Medical Use Desiccant

Buy Medical Use Desiccant

Industry Challenges

egulatory & Safety Compliance

- Meeting strict global regulations (FDA, EMA) for biocompatibility, safety (e.g., USP Class VI), and purity.

- Ensuring minimal leachables/extractables and comprehensive traceability.

- Proving safety for direct contact with drugs/devices, critical for all types (silica, montmorillonite, fiber, Ca/Mg chlorides).

Material Performance & Integrity

- Maintaining ultra-high material purity across all desiccant types to prevent product contamination.

- Ensuring compatibility with protected products (e.g., avoiding corrosion from chlorides like CaCl₂/MgCl₂, dusting from clays like attapulgite/montmorillonite).

- Preventing physical degradation (e.g., breakage, dusting) that could harm devices/drugs.

Packaging & Process Requirements

- Developing robust packaging (e.g., Tyvek® for silica gel, fiber) that withstands sterilization (gamma, ETO, e-beam) without failing.

- Minimizing linting/dust generation during handling and use (particularly relevant for clay desiccants vs. fiber).

- Ensuring packaging integrity maintains sterility barrier and desiccant function.

Validation & Performance Assurance

- Accurately calculating required desiccant capacity/correct type for diverse products and climate conditions.

- Demonstrating consistent and predictable adsorption performance across the product shelf life.

- Validating performance under real-world conditions with complex protocols.

Why Choose Our Desiccants

Enhanced Regulatory Assurance

Our desiccants consistently meet and exceed stringent global standards (FDA, EMA, USP/EP) for purity, biocompatibility, and safety documentation.

Superior Material Compatibility

Engineered to prevent contamination, corrosion, and interaction risks across all types (silica, chlorides, clays, fiber) with sensitive medical products.

Guaranteed Performance Reliability

Delivers predictable, high-efficiency moisture adsorption under diverse and extreme storage or transport conditions.

Comprehensive Supply Chain Support

Provides consistent quality, reliable availability, and technical expertise tailored to complex medical industry needs.

Optimized Safety & Cleanliness

Features minimized dusting, breakage, and leachables, ensuring physical and chemical safety for critical applications.

Usage

Pharmaceutical Packaging (Vials, Blister Packs)

Usage Overview

Desiccants (primarily silica gel and molecular sieves) are integrated into pharmaceutical packaging to protect moisture-sensitive drugs, tablets, and capsules from degradation.

Key Advantages

- Stability Maintenance: Prevents hydrolysis and maintains chemical integrity of active pharmaceutical ingredients

- Extended Shelf Life: Creates optimal low-humidity environments for hygroscopic medications

- Regulatory Compliance: USP/EP-grade silica gel meets pharmacopeia standards for direct drug contact

- Clean Operation: Non-dusting fiber desiccants prevent contamination in automated blister packing lines

Medical Device & Instrument Protection

Usage Overview

Montmorillonite, attapulgite, and silica gel canisters protect surgical tools, electronic equipment, and optical devices during sterilization, storage, and shipping.

Key Advantages

- Corrosion Prevention: Clay desiccants (montmorillonite/attapulgite) absorb moisture that causes metal instrument rust

- Electronics Safeguarding: Silica gel protects sensitive circuitry in diagnostic machines from humidity damage

- Physical Resilience: Non-friable formats resist breakage during device handling and transportation

- Sterilization Compatibility: Desiccant packaging maintains integrity after gamma/ETO sterilization cycles

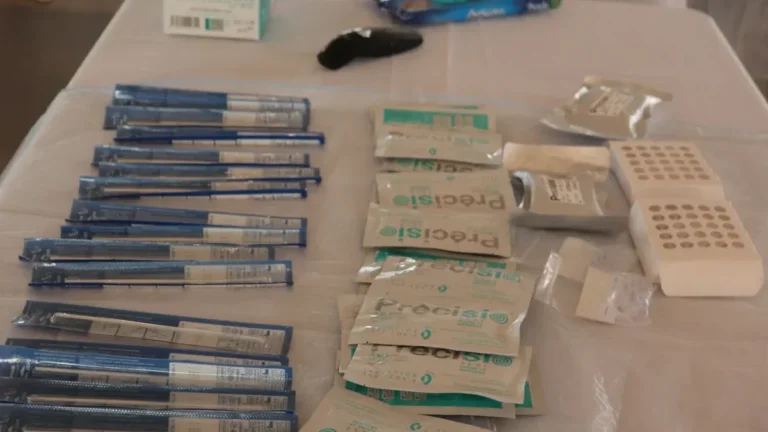

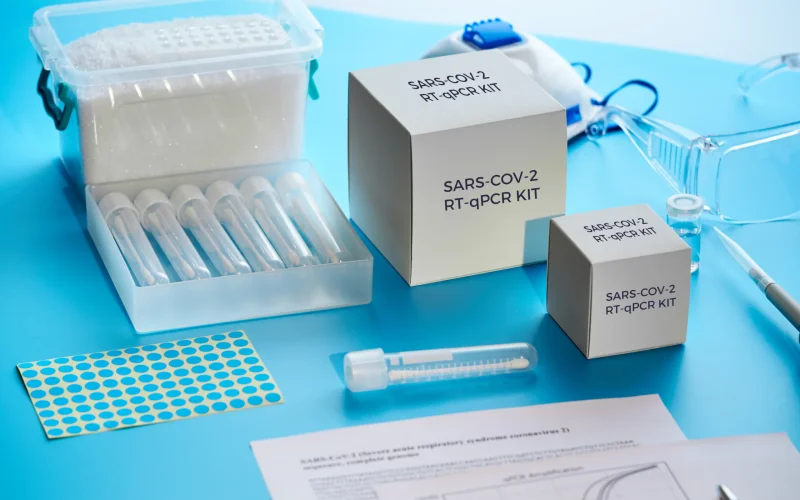

Diagnostic Reagent & Test Kit Preservation

Usage Overview

Silica gel and fiber desiccants preserve accuracy of diagnostic strips, reagents, and lateral flow test kits in hermetically sealed pouches.

Key Advantages

- Moisture-Sensitive Protection: Prevents premature activation of enzyme-based reagents

- Low Particulate: Fiber desiccants eliminate dust interference with microfluidic test components

- Uniform Performance: Provides consistent humidity control across varying temperature conditions

- Compact Integration: Slim-profile sachets fit within small test kit packaging without compromising function

Implantables & Sterile Barrier Systems

Usage Overview

High-purity calcium chloride (CaCl₂), magnesium chloride (MgCl₂), and silica gel maintain dry environments in sterile barrier packaging for implants and single-use devices.

Key Advantages

- Biocompatibility Assurance: Ultra-pure chlorides prevent leachables in direct implant contact scenarios

- High-Capacity Protection: Calcium chloride provides superior moisture absorption in long-term storage

- Temperature Resilience: Magnesium chloride maintains adsorption efficiency at elevated temperatures

- Sterility Maintenance: Compatible with all sterilization methods without generating endotoxins