Activated carbon is a very porous material. It is made to catch unwanted things from water, air, and other stuff. Its sponge-like shape has millions of tiny holes. These holes give it a big surface area for adsorption. In this process, molecules stick to the carbon’s surface. This lets it trap dirt, smells, and chemicals. Many industries use activated carbon. Water treatment, food and drink, medicine, and air cleaning all use it. They use it to take out bad things and make products better.

Key Takeaways

Activated carbon has lots of tiny holes. These holes trap dirt, chemicals, and smells from water and air. Its big surface area helps it catch many things. The holes come in different sizes. This makes it good at trapping many contaminants. There are four main forms of activated carbon. These are powdered, granular, extruded, and bead. Each form works best for certain cleaning jobs. Activated carbon is made from things like coconut shells, wood, coal, and farm waste. What it is made from changes how it works. Physical and chemical activation methods make the pores. These methods help carbon adsorb more impurities. Used activated carbon can be cleaned and used again. This saves money and cuts down on waste. Activated carbon is used in many places. It helps clean water, air, food, farms, mines, and medicine. Picking the right type and form depends on what needs cleaning. It also depends on the job and system needs.

How It Works

Adsorption

Activated carbon uses adsorption to clean things. In adsorption, molecules from liquids or gases stick to the carbon’s surface. This is not the same as absorption, where things soak inside a material. Activated carbon acts like a magnet for dirty stuff. It pulls out bad things from water or air and keeps them on its surface. How well this works depends on the carbon’s shape, especially its surface area and how many holes it has.

Surface Area

Activated carbon has a very large surface area for its size. One gram can have more than 3,000 square meters of surface. This big area gives lots of spots for bad stuff to stick. Scientists found that more surface area means more molecules can be trapped. Treatments like oxidation can make the surface area even bigger and help the carbon work better. Both the amount and how easy it is to reach the surface area matter for catching impurities.

Porosity

Porosity means there are many tiny holes and channels inside activated carbon. These holes come in different sizes. Micropores trap small molecules. Mesopores catch bigger organic compounds. Macropores can even hold tiny living things. Having all these types of holes lets activated carbon remove many kinds of contaminants. How the carbon is made, including what it’s made from and how it’s activated, changes the size and number of holes. More holes mean more places for molecules to stick, so the carbon works better.

Why It’s Effective

Activated carbon works really well because of its special structure and chemical features. Its large surface area and different pore sizes give it many places for adsorption. The surface also has special chemical groups that grab and hold different molecules. This helps it remove things like organic chemicals, chlorine, and some heavy metals from water and air.

Studies show activated carbon works better than other adsorbents like rice husk and sawdust. For example, it can hold onto contaminants like chromium (Cr(VI)) for longer and remove more of them. The table below shows how well different adsorbents work:

Adsorbent | Breakthrough Time Range (min) | Cr(VI) Removal Efficiency (%) |

|---|---|---|

Activated Carbon | 37.71 – 66.32 | |

Rice Husk | 6.13 – 12.04 | 31.07 – 56.56 |

Sawdust | 5.93 – 11.85 | 31.19 – 52.96 |

Activated carbon can take out many kinds of contaminants, such as:

Organic compounds like solvents, pesticides, and industrial chemicals

Chlorine and chloramines from water

Disinfection byproducts like trihalomethanes (THMs)

Some heavy metals, like lead (with special filters)

Note: How well activated carbon works depends on the type used, how long water or air touches it, and what contaminants are there.

The mix of big surface area, different pore sizes, and chemical attraction makes activated carbon a great choice for cleaning water, air, and other things.

Types and Forms

Powdered

Powdered Activated Carbon (PAC) has very tiny particles. These are usually between 10 and 50 micrometers. The small size gives PAC a high surface area. This helps it grab contaminants quickly. Water plants add PAC to mix basins or water intakes. They also use it in clarifiers. The fine particles catch small molecules fast. This makes PAC good for quick impurity removal.

Norit NV is a big company that makes PAC. Their PAC is used in many industries. PAC works well in carbon block filters. It is also used for emergency water treatment. It acts fast and can be added when needed. PAC is also used in food and drink processing. It helps remove bad tastes and smells.

Tip: PAC is great for treating water when there is sudden contamination.

Form of Activated Carbon | Particle Size | Surface Area | Typical Applications |

|---|---|---|---|

Powdered (PAC) | 10–50 µm | Very high | Rapid mix basins, clarifiers, carbon block filters, emergency use |

Granular

Granular Activated Carbon (GAC) has bigger particles than PAC. These are usually 0.42 to 0.84 millimeters. GAC has less outside surface than PAC. But it lets water and air flow through easily. GAC is used in water treatment, air purification, and deodorization. It is good at removing organic compounds, chlorine, and VOCs.

Norit NV makes GAC in different sizes. This helps fit many filter systems. Cities, homes, and factories use GAC. It is strong and works well for a long time. GAC can be cleaned and used again. This makes it useful for big jobs.

Common uses for GAC:

Drinking water filters

Aquarium filters

Cleaning industrial gases

Controlling smells in wastewater

Form of Activated Carbon | Particle Size | Surface Area | Typical Applications |

|---|---|---|---|

Granular (GAC) | 0.42–0.84 mm | High | Water treatment, air filtration, deodorization, gas purification |

Extruded (Pelletized)

Extruded Activated Carbon (EAC) is made into small cylinders. These are between 0.8 and 130 millimeters wide. EAC is made by mixing powdered carbon with a binder. Then it is shaped into even pellets. EAC has high mechanical strength and makes little dust. This makes it good for cleaning gases. The cylinder shape lets air or gas move easily. This means there is a low pressure drop in the filter.

Industries use EAC in CTO filters. These are for cleaning air and gases. Norit NV makes EAC to be strong and work well. EAC lasts long and keeps its shape. It is a top pick for places with lots of use or fast flow.

Note: EAC’s strong build helps it work well in tough places like chemical plants and big air cleaning systems.

Form of Activated Carbon | Particle Size/Shape | Surface Area | Typical Applications |

|---|---|---|---|

Extruded (EAC) | Cylindrical, 0.8–130 mm | High | Gas phase filtration, CTO filters, industrial air cleaning |

Bead

Bead activated carbon (BAC) is a special kind of activated carbon. It comes as small, round beads. These beads are between 0.35 and 0.80 millimeters wide. The beads offer a uniform size and shape. This helps them work well in filters. The round beads pack together evenly. This lets water or air move through easily. The design stops clogging and keeps pressure low. BAC is good for systems that run all the time.

BAC provides a high surface area and consistent porosity. Each bead has thousands of tiny holes. These holes catch things like organic chemicals, smells, and some heavy metals. The even size of the beads makes the whole filter work well. BAC does not break apart easily. It lasts a long time, even in tough jobs.

Note: People pick bead activated carbon because it is strong and can be cleaned many times.

Norit NV is a big company that makes BAC. Their BAC is very pure and works well. Norit NV’s BAC is used to clean water and air. Their products take out bad tastes, smells, and chemicals from drinking water. BAC also grabs VOCs and gases in air cleaning.

Typical applications for bead activated carbon include:

Water purification: BAC is used in city water plants, home filters, and fish tanks. The beads take out chlorine, pesticides, and other organic stuff.

Air and gas treatment: Factories use BAC to clean gases and stop bad smells. The beads work in packed bed filters and gas masks.

Pharmaceutical and food industries: BAC helps clean ingredients and remove colors or tastes from products.

Solvent recovery: BAC beads catch and save useful solvents in chemical plants.

Feature | Benefit |

|---|---|

Uniform bead shape | Even flow, less clogging |

High mechanical strength | Long lifespan, resists breakdown |

Consistent porosity | Reliable adsorption of contaminants |

Easy regeneration | Can be cleaned and reused |

BAC can be cleaned and used again. This makes it good for the environment. Cleaning the beads means less waste and lower costs. The round shape also makes it easy to handle and fill filters.

Production

Raw Materials

Activated carbon is made from carbon-rich raw materials. Companies pick the source based on what they need. The most used materials are coconut shell, wood, coal, and agricultural waste. Each one gives activated carbon special traits. These traits change how dense, hard, or ashy it is. They also change the size and shape of its pores.

Coconut Shell

Coconut shell activated carbon is very hard and dense. It has little ash and almost no heavy metals. Most of its pores are micropores. This makes it great for dechlorination and water treatment. Coconut shell chars activate faster than other farm sources. Their special makeup helps this happen. Fast activation means more micropores form. These tiny pores trap small contaminants well.

Wood

Wood-based activated carbon is less hard and dense than coconut shell or coal. It has more ash. It has lots of mesopores and macropores. These help remove big organic molecules. Wood-based carbon is used for decolorization. It is also used in food processing, pharmaceuticals, and drinking water purification.

Coal

Coal activated carbon is strong and dense. It has more ash and some heavy metals. Its pores are both mesopores and micropores. This helps it adsorb gases like volatile organic compounds (VOCs) and hydrogen sulfide. Coal-based carbon is best for industrial waste gas treatment and air purification.

Property | Coconut Shell Activated Carbon | Coal Activated Carbon | Wood Activated Carbon |

|---|---|---|---|

Density | Very high (0.48 – 0.58 g/cc) | High (0.38 – 0.48 g/cc) | Low (0.25 – 0.30 g/cc) |

Hardness | Very high (≥98%) | High (90-95%) | Low (≥85%) |

Ash Content | Very low (max 3%) | High (max 10%) | Very high (max 15%) |

Porosity | Predominantly micropores | More mesopores and some micropores | More mesopores and macropores |

Wettability | Very high | Normal | Low |

Heavy Metals | Not traceable | Present | Low |

Best Applications | Dechlorination, water treatment | Odor removal, industrial waste gas treatment | Decolorization, removal of macromolecular organics |

Activation Methods

There are two main activation methods for making activated carbon. These are physical activation and chemical activation. The method changes the pore size, surface area, and how well it adsorbs.

Physical

Physical activation has two steps. First, carbonization burns the material. This opens up pores between carbon plates. Next, activation uses gases like steam or carbon dioxide. The carbon is heated to high temperatures (500–1000 °C). Oxygen in the gases reacts with carbon. This makes carbon monoxide and carbon dioxide. These gases leave and make more pores. The result is a very porous structure with different pore sizes. Physical activation is good for the environment. It does not use chemicals and lets makers control the pores.

Chemical

Chemical activation uses chemicals like phosphoric acid. Makers soak the raw material in the chemical. Then they heat it at lower temperatures (400–700 °C). Chemical reactions make phosphate bridges. These bridges help form the pores. After heating, the carbon is washed to remove leftover chemicals. The final activated carbon has special pore sizes and surface chemistry. Chemical activation works well for wood and farm waste. It makes carbons with more mesopores and macropores.

Sustainability Note:

Using waste like farm leftovers and city trash to make activated carbon helps manage waste. It also lowers disposal costs. Activated carbon from waste cleans air and water. This gives new value to old materials. Physical activation is better for nature. Used carbon can be cleaned and used again. This makes it last longer. Scientists keep working to make recycling better and cut waste. Activated carbon is a smart and green choice for many jobs.

Activated Carbon Properties

High Surface Area

Activated carbon has a very large surface area. This helps it catch many kinds of contaminants. Most activated carbon has between 600 and 1200 square meters per gram. Some special types can reach up to 2800 square meters per gram. These special types are not used every day. The big surface area gives more places for molecules to stick. This makes activated carbon great for cleaning water, air, and other things. Many industries use it because of this feature.

Porosity

Porosity means there are lots of tiny holes inside activated carbon. These holes come in different sizes. Each size helps with adsorption in its own way:

Micropores and mesopores are very small. They help the carbon catch natural organic matter and small molecules.

Macropores are bigger. They help bacteria grow in biological filters. These bacteria break down contaminants and clean water more.

Having all three types of pores lets activated carbon remove many impurities. The mix of pore sizes is important for chemical and biological cleaning.

Tip: Pick activated carbon with the right pore sizes for the contaminants you want to remove.

Chemical Stability

Activated carbon is very stable in many places. Its structure keeps it safe from most chemicals. It works well even after being used for a long time. Activated carbon does not react much with water, acids, or bases. This means it can be used in tough jobs and pollution control. It also does not break down easily in wet conditions. This helps it last longer in filters and treatment systems. Its strength and resistance make it a good choice for cleaning and protecting the environment.

Regeneration

Regeneration lets used carbon be used again after it traps contaminants. This process brings back the carbon’s ability to adsorb, so it saves money and helps the environment. Many industries use regeneration to keep carbon working well and to cut down on waste. There are different ways to do this, like using heat, chemicals, or both together. Each way has its own good points.

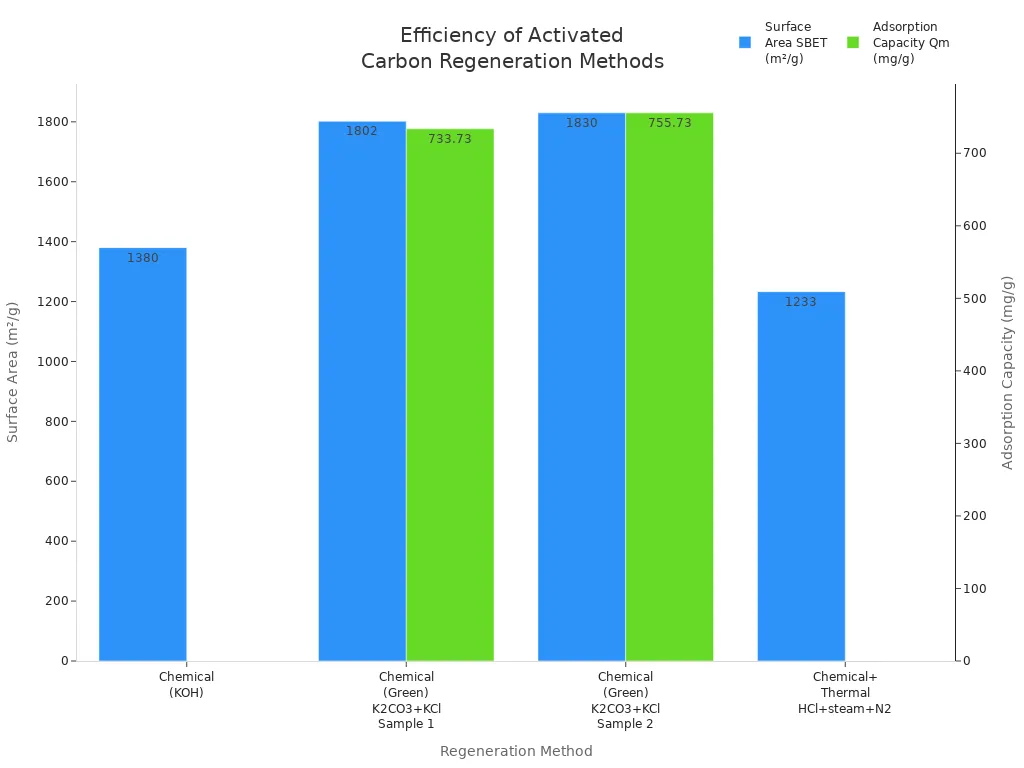

Thermal regeneration uses very high heat to get rid of trapped substances. Superheated steam is a special thermal method that works well. It uses hot water vapor at 500°C for one hour. This makes the carbon cleaner and more efficient than just using chemicals. Chemical regeneration uses things like potassium hydroxide (KOH) or safer chemicals such as potassium carbonate (K2CO3) and potassium chloride (KCl). These chemicals help make more surface area and better adsorption, but some can be dangerous or harmful. Using both chemical and thermal methods together can make even more surface area and more holes, so the carbon works better.

Activating Agent(s) | Efficiency Metrics (Surface Area SBET, m²/g) | Adsorption Capacity (Qm, mg/g) | Notes | |

|---|---|---|---|---|

Thermal | – | Widely used industrially | N/A | Most extensively used industrial method |

Chemical | KOH | Up to 1380 m²/g | N/A | High surface area but corrosive and environmentally challenging |

Chemical (Green) | K2CO3 + KCl | Increased SBET from 3 & 592 to 1802 & 1830 | 733.73 & 755.73 | Green chemicals, high carbon yield (73%), reusable agents, less hazardous |

Chemical + Thermal | Oxalic acid + thermal air | Improved surface area and porosity | N/A | Two-step regeneration more effective than single-step |

Chemical + Thermal | HCl washing + steam + N2 | Increased SBET from 838 to 1233 | N/A | Enhanced surface area by combined chemical and thermal treatment |

Other Chemicals | NaOH, H3PO4, ZnCl2 | N/A | N/A | Effective but corrosive/toxic, costly protective measures needed |

Regeneration is good for the environment in many ways. Recycling used carbon means less new carbon is needed, so fewer resources are used and less waste is made. Thermal regeneration destroys the trapped contaminants, so the carbon can be safely used again. This helps companies save money and follow rules about waste. Regeneration also keeps waste out of landfills, supports recycling, and keeps carbon working well through many uses.

Tip: Regenerating carbon saves money and helps protect the environment by making less landfill waste and lowering the carbon footprint.

Description | |

|---|---|

Disposal Cost & Liability | Regenerated carbon eliminates costs and liabilities related to spent carbon disposal. |

Virgin Carbon Demand | Recycling reduces the need to purchase fresh carbon, lowering resource consumption. |

Contaminant Destruction | Thermal regeneration destroys adsorbed contaminants, enabling safe reuse and reducing waste volume. |

Regulatory Compliance | Recycling helps meet waste reduction regulations such as RCRA and Executive Orders. |

Economic Savings | Annual savings reported due to reduced disposal and purchase costs. |

Regeneration keeps carbon useful and eco-friendly for cleaning water, air, and in factories. Being able to bring back adsorption and use carbon again makes regeneration very important for taking care of the environment today.

Activated Carbon Applications

Water Treatment

Activated carbon is very important in water treatment. It takes out many contaminants from water. These include organic compounds, chlorine, pesticides, and PFAS. Granular activated carbon (GAC) filters work well for removing PFAS. New GAC filters can take out 92% to 100% of PFAS from drinking water. As the filter gets older, it does not work as well. Changing how fast water moves through the filter can help it keep working. Water plants, homes, and factories use activated carbon. It makes water taste better and removes bad smells. It also helps keep water safe to drink. Using this technology helps protect people’s health. It lowers the amount of harmful chemicals in water and makes it cleaner for daily use.

Tip: Change or clean activated carbon filters often to keep them working well for water purification.

Air & Gas Treatment

Activated carbon is used a lot to clean air and gases. Its tiny holes trap VOCs, odors, and other pollutants. This happens through adsorption. Studies show these filters can remove over 90% of VOCs. They can also cut smoke smells by 85% or more indoors. Activated carbon filters lower ozone levels by up to 90%. How well they work depends on how much carbon is in the filter. It also depends on how long air touches the carbon and the type of filter. Pellet filters have more activated carbon. They last longer and clean better than thin filters. It is important to check and replace filters on time. This stops them from getting full and keeps the air clean.

Activated carbon filters make indoor air healthier by taking out bad gases and smells.

New Energy

Activated carbon helps new energy technology, especially for gas storage. It acts as a porous adsorbent for methane. When it is wet, it helps form methane clathrate hydrates in its pores. This lets it store more methane than when it is dry. Tests show wet activated carbon can hold 6 to 17 mol of methane per kilogram. Dry carbon can hold up to 36 mol per kilogram. The amount stored depends on the material and conditions. These storage methods need cold temperatures and high pressure. This makes it hard to use in natural gas cars and trucks. Even with these problems, activated carbon is still a good choice for clean energy storage.

Using activated carbon in new energy helps make fuel storage better and more sustainable.

Food & Beverage

The food and beverage industry must keep products safe and pure. Companies use special filters to take out things they do not want. This helps make food and drinks taste and look better. Activated carbon is important for this job. It grabs and holds onto bad stuff, colors, and smells in liquids and ingredients.

Different types of carbon are used for different jobs. Coconut shell carbon is good for oils and drinks because it is very pure and works well. Wood carbon is picked for making wine clear and cleaning sugar. Powdered carbon is fast at cleaning liquids. Granular carbon is used in big factories for steady filtering. New ideas like tiny powders and nano-carbons help with clean and organic foods. Rules say harmful things like mycotoxins, pesticides, and heavy metals must be removed. Using carbon helps companies follow these rules and keep people safe.

Purpose of Use | Type Used | Regulatory/Quality Aspect | |

|---|---|---|---|

Water Treatment | Remove chlorine, chloramines, pollutants | Not specified | Ensures water meets food safety standards |

Fruit Juice Production | Remove unwanted taste and color | Selection based on effectiveness | Enhances taste and appearance, meets quality requirements |

Beer, Wine, Spirits | Remove fusel alcohols, methanol, sulfur, organics | Chemically or steam-activated | Ensures product consistency and safety |

Sweeteners | Dechlorination, remove flavor/color impurities | Chemically or steam-activated | Ensures purity and quality of sweeteners |

Glycerin Purification | Remove colors, odors, fatty acids | Granular and powdered | Ensures high-quality glycerin |

Edible Oils | Remove toxins (e.g., PAHs), color modification | Not specified | Removes carcinogens, ensures safety |

Citric Acid, MSG, Gelatin | Decolorization, deodorization, impurity removal | Granular and powdered | Meets purity and safety standards |

Food makers pick food-grade carbon to meet tough safety rules. This keeps food and drinks safe, tasty, and legal.

Agriculture

Farmers and water workers use carbon materials to clean farm water. These carbons come from things like waste hemp, sugarcane molasses, and old tires. They are very good at taking out pesticides from water. For example, hemp carbon can remove pesticides like acetamiprid and atrazine. Carbon from old tires can take out 70-90% of chemicals such as methoxychlor and methyl parathion.

Granular carbon and carbon fabric are the main types used on farms. Carbon fabric has lots of tiny holes and a big surface area. It can remove up to 92% of some pesticides in tests and about 50% in real farm water. Water moves through carbon fabric quickly, so it does not clog like other filters. These tools help keep crops safe, stop chemicals from running off, and make farm water cleaner.

Using waste carbon is a green way to fight farm pollution.

Carbon fabric and granular carbon work fast and well to remove pesticides.

These materials help farmers follow rules and keep water clean.

Metal Mining

Mining companies use carbon to get gold from ore. In the Carbon-in-Leach process, carbon acts like a sponge. It grabs gold-cyanide complexes from the mix. Coconut shell granular carbon helps get 12-18% more gold than coal carbon. Using carbon in this process gets over 95% of the gold, which is much better than other ways.

The carbon used in mining must be very hard and have little ash. Acid-washed carbon can reach up to 99.5% elution and uses less cyanide. Closed systems with coconut shell carbon keep recovery high and help stop dirty water from leaving the mine. Special carbons with changed surfaces help get gold from hard ores. Using good carbon saves money, works better, and is better for the environment.

Carbon-in-Leach with carbon gets over 95% of the gold.

Coconut shell carbon works better and is more earth-friendly.

Carbon that can be used again saves money and helps the planet.

Medical

Doctors use special carbon materials for many treatments. These materials help in emergencies and wound care. They also help with some stomach problems. Doctors use them to treat poisoning from drugs or chemicals. The carbon traps toxins in the stomach and intestines. This stops toxins from getting into the blood. This method is safe for many poisonings. But it does not work for every substance.

Healthcare workers use carbon dressings for wounds. These dressings soak up bacteria and bad smells. Some dressings have silver with carbon to heal faster. Studies show these dressings help wounds heal quickly. They also keep wounds clean. The World Health Organization says medical carbon is very important. It is needed in hospitals around the world.

Common medical uses include:

Treating poisonings from drugs like phenobarbital and carbamazepine

Managing some cases of diarrhea, indigestion, and flatulence

Using carbon dressings for chronic wounds, especially when combined with silver

Supporting gastrointestinal decontamination in hospitals

Note: Medical carbon does not work for poisonings caused by strong acids, bases, iron, lithium, arsenic, methanol, ethanol, or ethylene glycol. Doctors choose when to use it based on each patient’s needs.

Chemical

Factories use carbon materials to keep products clean. These materials help remove unwanted chemicals. They also protect machines and help companies follow safety rules. Factories use carbon to clean water and catch harmful gases. Carbon helps keep catalysts working longer. In medicine making, carbon keeps places clean and stops contamination.

The table below shows how different industries use carbon and what benefits they get:

Industry Process | Use of Carbon Material | Benefits in Product Purity / Process Efficiency |

|---|---|---|

Oil and Gas Refining | Removal of sulfur and nitrogen compounds; capture of VOCs; treatment of process water; catalyst protection; product purification | Improves product quality by removing contaminants; prolongs catalyst life; ensures regulatory compliance; enhances product stability |

Chemical Processing | Adsorption of hazardous chemicals to prevent environmental release | Enhances safety and environmental compliance |

Pharmaceutical Processing | Adsorption of toxins and pollutants to maintain sterile environments and prevent contamination | Enhances product purity and safety |

Food and Beverage | Removal of unwanted chemicals, odors, and microorganisms | Ensures safety, quality, and regulatory compliance of food and beverages |

Radioactive Gas Removal | Adsorption of radioactive iodine and organic iodides in nuclear plants | Protects workers and environment; ensures safety |

Companies pick carbon materials because they target certain contaminants. They also help save money and meet tough rules. These materials help make safer products. They protect workers and the environment.

Choosing Activated Carbon

Application Needs

Picking the right carbon starts with knowing what you need. Each job, like cleaning water or air, needs different features. The kind of contaminant and how much is present matter a lot. The place where you use the carbon also changes what works best. For example, to remove organic chemicals from water, you need carbon with lots of surface area and small pores. Gas filters work better with bigger pores and strong carbon.

Some important things to think about are:

Surface area and pore size decide what and how much can be trapped.

Surface chemistry helps the carbon grab certain molecules.

The form, like granular, powdered, or extruded, fits the job and if it’s for liquid or gas.

Rules and how the system runs, like flow speed and when the filter gets full, also matter.

Tip: Always pick carbon that matches the contaminants and how you plan to use it for the best results.

Type Selection

The shape and size of carbon affect how well it works for each job. The table below shows common types and what they are used for:

Form | Particle Size Range | Application Phase | Key Properties | Typical Use Case |

|---|---|---|---|---|

Powdered (PAC) | 5 to 150 Å (very small) | Liquid | Fast adsorption, flexible dosing | Water treatment, emergency use |

Granular (GAC) | 0.2 mm to 5 mm | Liquid & Gas | Durable, regenerable, easy handling | Drinking water, air purification |

Extruded (EAC) | 1 mm to 5 mm pellets | Gas | High strength, low dust, robust | Industrial gas filtration |

Bead | Not specified | Not specified | Uniform shape, consistent porosity | Specialized filtration systems |

What you need, like if it’s for liquid or gas, the size of the particles, and if you want to reuse the carbon, all help you choose. PAC is good for liquids because it is fine and easy to use. EAC is best for tough gas jobs.

Cost Factors

Cost is more than just the price you pay at first. Where the carbon comes from, how it is made, and how well it works all change the total cost. Carbons made from wood or coal are cheaper but may need to be replaced more often. Better carbons last longer and work better but cost more at the start. Reactivated carbon is a smart choice because it saves money and is better for the planet.

Other things that change the price are:

If there are not enough raw materials, like coconut shells or coal, prices go up.

More energy use and new rules can make making carbon cost more.

Shipping problems and world supply issues can make prices change a lot.

Companies might raise prices if raw materials cost more or rules change.

Note: Reactivated carbon can cost 20-30% less than new carbon and helps the environment.

Activated carbon is great at catching impurities and making things cleaner. Its many tiny holes and different shapes help in water, air, food, and factories.

Many industries use it to filter and clean things well.

Now, making activated carbon uses more renewable materials, which is better for nature.

Cleaning and reusing it means less waste and helps the planet.

More people want eco-friendly products, so the market is growing and rules are getting tougher.

People and companies can pick activated carbon to make things safer, healthier, and better for the environment.