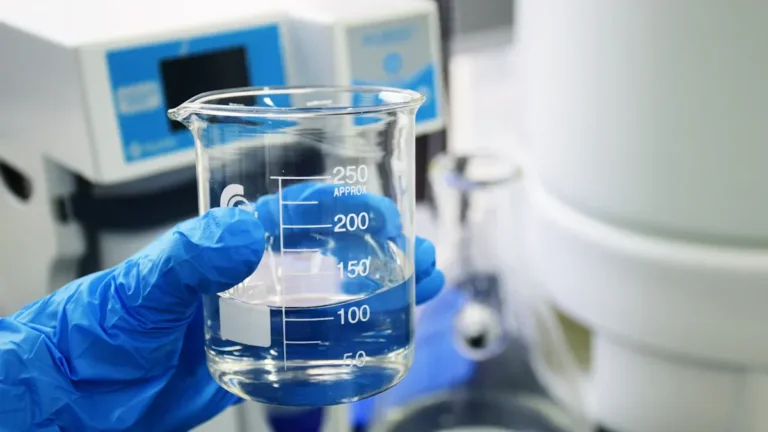

Metal Removal Activated Carbon

.webp)

Buy Metal Removal Activated Carbon

Industry Challenges

Selectivity Constraints

- Activated Carbons have differing adsorption efficacy when removing various metals (e.g., improved removal of lead but low removal of copper/iron).

- Chemically modified MRAC concentrates its efficacy, but is ultimately also limited when treating complex multi-metal streams as in mixing mining effluents that contain gold, silver, zinc or nickel.

Competitive Interference

- Non-target ions (calcium, organic compounds) compete with heavy metals (cadmium, copper) for adsorption sites in industrial wastewater.

- pH fluctuations further disrupt binding stability and ion selectivity.

Regeneration Limitations

- Recovering precious metals (silver, gold-cyanide complexes) via acid washing is inefficient.

- Incomplete impurity removal (iron/calcium salts) and reduced metal recovery rates occur during regeneration cycles.

Material Degradation

- Repeated regeneration diminishes porosity and functional group effectiveness.

- Pore blockage from oils/organics or chemical degradation necessitates frequent carbon replacement.

Hazardous Waste Management

- Spent carbon loaded with toxic metals requires specialized hazardous waste disposal.

- Sustainable regeneration technologies remain underdeveloped, creating logistical and environmental burdens.

related types of activated carbon

-r8fslg51nt6wgjtvh6yldxb1gtkgm3lpe0oq1akgog.webp)

- Iodine Value: 600-1200

- Mesh Size: 1×4/4×8/8×16/8×30/12×40/20×40/20×50/30×60/40×70 (More size on request)

- Apparent Density: 400-700

-r8fsli0q1h9h3rr567ruiwtynlb71ht629zozuhoc0.webp)

- Iodine Value: 500-1300

- Mesh Size:0.9-1mm/1.5-2mm/3-4mm/6mm/8mm(More size on request)

- Apparent Density: 450-600

-r8fslbfupn0gui0p8mxgjghqhw7mjm31pdfamwrfjk.webp)

- Iodine Value: 500-1300

- Mesh Size: 150/200/300/350 (More size on request)

- Apparent Density: 450 – 550

-r8fsle9da54btbwls65c8xs4a1tq6pe8prdr2qn90w.webp)

- Iodine Value: 400-800

- Mesh Size: 100×100×100mm/100×100×50mm (Custom cell density on request)

- Apparent Density: 350-450

- Bore Diameter:1.5-8mm

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 300-650 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Activation Method: Steam/gas activation at high temperatures

- Pore Structure: Microporous-dominated, uniform pore distribution

- Environmental Profile: Chemical-free, low ash content

- Primary Applications: Gas-phase adsorption, drinking water purification

- Activation Method: Chemical activation (e.g., H₃PO₄/ZnCl₂) at moderate temperatures

- Pore Structure: Mesoporous-rich, higher surface area

- Process Efficiency: Shorter activation time, 30-50% higher yield

- Post-Treatment: Acid-washing required to remove residues

- Functionalization: Loaded with active agents (e.g., I₂/Ag/KOH)

- Targeted Adsorption: Enhanced capture of specific pollutants (e.g., Hg⁰/H₂S/acid gases)

- Customization: Chemically optimized for target contaminants

- Core Applications: Industrial gas treatment, CBRN protection

Why Use Our Activated Carbon

Superior Adsorption Selectivity:

For precious and heavy metals due to engineered surface functional groups.

Enhanced Mechanical Durability :

Minimizes carbon loss during regeneration cycles in harsh mining environments.

Optimized Pore Structure :

Maximizes metal-loading capacity while resisting pore blockage from organic contaminants.

Sustainable Regeneration Capability

Maintains high performance through multiple thermal/reactivation cycles.

Proven Efficiency

In complex multi-metal streams like acid mine drainage and mineral processing effluents.

Process and Technolog

1. Precious Metal Recovery from Mining Wastewater

Solution Overview

Activated carbon adsorbs residual gold, silver, and other valuable metals from mineral processing wastewater (e.g., cyanide tailings). Parameters like carbon type, pH, and flow rate are optimized to maximize metal recovery.

Key Advantages

- Selective adsorption: Targets low-concentration precious metals (e.g., 0.3 g/t gold) even in complex wastewater streams.

- Resource circularity: Transforms waste (e.g., tailings) into a metal resource, aligning with sustainable mining practices.

- Process flexibility: Tunable via carbon modification (e.g., acid-washed or OMC carbons) to enhance metal-binding capacity.

2. Heavy Metal Remediation in Acid Mine Drainage

Solution Overview

Acid-modified activated carbon treats Sb²⁺, As, and other heavy metals in mining-impacted soils or acidic pit water. A two-stage adsorption process at optimized pH (e.g., pH 5) immobilizes metals via surface complexation.

Key Advantages

- Multi-metal capture: Simultaneously immobilizes Sb (up to 97%) and As (up to 67%) by suppressing Fe(III) reduction and DOM shuttling in flooded soils.

- Enhanced material properties: Acid modification increases surface area and acidic functional groups, improving adsorption kinetics.

- Regulatory compliance: Reduces Sb²⁺ to <0.02 mg/L, meeting surface water Class III standards.

3. Soil Remediation for Mining-Impacted Areas

Solution Overview

Activated carbon amendments reduce mobilization of Sb and As in flooded mine soils by adsorbing dissolved organic matter (DOM), which inhibits microbial Fe(III) reduction and subsequent metal release.

Key Advantages

- Risk mitigation: Lowers bioavailability and leaching of toxic metals, preventing entry into the food chain.

- Long-term stability: Maintains metal immobilization under anaerobic conditions typical of flooded mine sites.

- Material superiority: Outperforms biochar in DOM adsorption due to higher microporosity and surface functionality.

4. Advanced Carbon Modifications for Enhanced Performance

Solution Overview

Oxidatively Modified Carbon (OMC) or MMT-impregnated carbon are engineered for superior gold adsorption. OMC mimics graphene oxide's structure for high gold-cyanide affinity, while MMT-carbon enables full thermal regeneration.

Key Advantages

- Superior capacity: OMC exceeds commercial carbons in gold adsorption due to GO-like surface chemistry; MMT-carbon achieves 100% desorption with thiosulfate.

- Eco-regeneration: MMT decomposes completely into gases, eliminating secondary waste.

- Renewable material: Coconut shell-based carbons offer high microporosity (>85% surface area), mechanical strength, and low ash content.