Granular Activated Carbon (GAC)

.webp)

Buy Granular Activated Carbon (GAC)

Key Characteristics Of granular activated carbon (GAC)

Physical Properties:

- Particle size typically ranges from 0.2 to 5 mm in diameter

- Common mesh sizes include 8x30, 12x40, and 20x50

- High surface area, often between 500 to 1500 m²/g

- Low bulk density, usually ranging from 0.4 to 0.7 g/cm³

Structural Features:

- Well-developed network of micro, meso, and macropores

- Pore volume typically ranges from 0.7 to 1.8 cm³/g

- Irregular particle shape allowing for efficient packing

Chemical Properties:

- pH generally between 6 to 11, depending on activation method

- Ash content usually less than 15%

- Moisture content typically below 5%

Performance Attributes:

- Iodine number ranging from 600 to 1200 mg/g

- Methylene blue adsorption value between 150-300 mg/g

Thermal Properties:

- Ignition temperature above 400°C

- Thermal conductivity around 0.1-0.2 W/m·K

related types of activated carbon

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 300-650 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Activation Method: Steam/gas activation at high temperatures

- Pore Structure: Microporous-dominated, uniform pore distribution

- Environmental Profile: Chemical-free, low ash content

- Primary Applications: Gas-phase adsorption, drinking water purification

- Activation Method: Chemical activation (e.g., H₃PO₄/ZnCl₂) at moderate temperatures

- Pore Structure: Mesoporous-rich, higher surface area

- Process Efficiency: Shorter activation time, 30-50% higher yield

- Post-Treatment: Acid-washing required to remove residues

- Functionalization: Loaded with active agents (e.g., I₂/Ag/KOH)

- Targeted Adsorption: Enhanced capture of specific pollutants (e.g., Hg⁰/H₂S/acid gases)

- Customization: Chemically optimized for target contaminants

- Core Applications: Industrial gas treatment, CBRN protection

Benefits

High Adsorption Capacity

GAC boasts an impressive iodine value of up to 1300 mg/g, indicating exceptional adsorption capabilities for a wide range of contaminants.

Versatile Particle Sizes

Available in multiple mesh sizes (48, 816, 510, 612, 830, 2040), allowing for customization to specific application needs.

Low Moisture Content

With moisture content <5%, GAC ensures efficient adsorption and minimal interference in treatment processes.

Adjustable pH

Customizable pH values (6.5-9) to suit various environmental conditions and treatment requirements.

High Purity

Low ash content (<2.5%) guarantees high purity and minimal impurities, enhancing overall performance.

Diverse Applications

Suitable for various uses including sewage treatment, waste gas treatment, gold refining, and high-end water purification.

Superior Raw Material

Produced from high-quality coconut shells, offering excellent hardness and durability for extended service life.

Applications

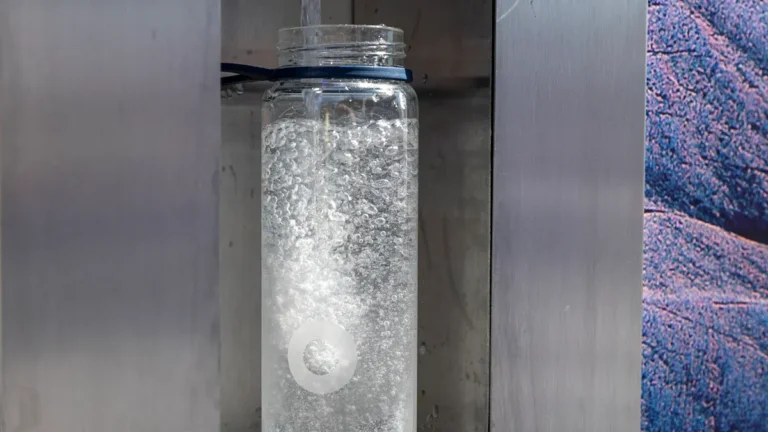

Water Treatment

Gas Treatment

Gold Recovery

Food Industry

shipping service

20kg/bag;25kg/bag;500kg / bag

Customized customer branded bags or other weight bags

Shipped by sea and air.

Sample delivery method: DHL, FedEx, etc.

FAQ

Packaging & Transportation Desiccant

Silica gel desiccants are necessary to protect products in transit and storage. Silica gel desiccants are packaged in breathable sachets or canisters, and manage humidity in shipping containers, cartons, and crates. Silica gel absorbs moisture in the ambient air, and prevents condensation, mold, metal corrosion, and damage to moisture sensitive materials. Silica gel is perfect for electronics, machinery, art, and paper products, to ensure items arrive in the right condition no matter what climate change may have occurred during the logistics of global transport.

Electronics Industry

Silica gel is well known for its moisture control properties in electronic manufacturing and storage. Proper protection of sensitive components is critical, especially in packaging of items such as circuit boards, semiconductors, or optical devices. By using silica gel in sealed packages, or sealed cabinets, electronics are kept in low-humidity environments. This reduces the risks of unforeseen damage to components from oxidation, electrical shorts, and performance failures of any kind. The properties of silica gel, non-corrosive, dust-free, and safe for direct contact with delicates parts, ensures safe shipping and handling from factoryels in an unopened condition.

Pharmaceutical Industry

Silica gel provides vital moisture prevention in medicine bottles, diagnostic kits and as a component of medical device packaging. Silica gel satisfies FDA and pharmacopeia requirements and protects tablets, capsules, and laboratory reagents from both moisture-driven degradation and elevated moisture levels. Importantly, silica gel acts to stabilize humidity levels in sealed environments extending shelf-life, sterility, and therapeutic effectiveness or viability. Silica gel packets not only work well to smooth out humidity changes, but they are also transparent which allows a visual inspection. Furthermore, cobalt-free silica gel packets pose no toxicity issues in deliberately sensitive applications.

Food Industry

Silica gel provides vital moisture prevention in medicine bottles, diagnostic kits and as a component of medical device packaging. Silica gel satisfies FDA and pharmacopeia requirements and protects tablets, capsules, and laboratory reagents from both moisture-driven degradation and elevated moisture levels. Importantly, silica gel acts to stabilize humidity levels in sealed environments extending shelf-life, sterility, and therapeutic effectiveness or viability. Silica gel packets not only work well to smooth out humidity changes, but they are also transparent which allows a visual inspection. Furthermore, cobalt-free silica gel packets pose no toxicity issues in deliberately sensitive applications.

Related Blog