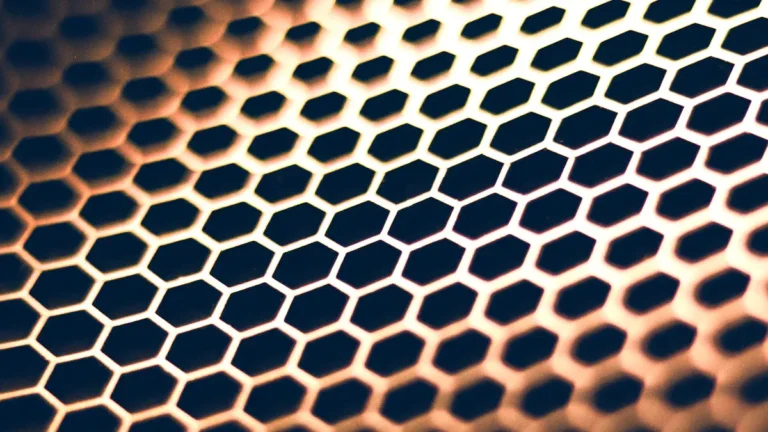

Honeycomb Activated Carbon

.webp)

Buy Honeycomb Activated Carbon

Key Characteristics Of Honeycomb Activated Carbon

Structure:

- Distinctive honeycomb-shaped configuration

- Uniform, parallel channels throughout the material

Manufacturing Process:

- Produced using advanced activated carbon preparation technology

- Undergoes strict quality control from raw material selection to finished product

Raw Materials:

- May be derived from various sources such as coconut shells, wood, or coal

- Selection of high-quality raw materials ensures product stability

Quality Assurance:

- Meets national standards and international certifications

- Undergoes rigorous testing at every production stage

Customization:

- Can be tailored to meet specific customer requirements

- Part of a diverse product portfolio to suit various applications

Environmental Considerations:

- Produced with a focus on environmental protection and sustainability

- Designed to be environmentally friendly and non-toxic

related types of activated carbon

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 300-650 kg/m³

- Iodine Value: 700-1200 mg/g

- Surface Area: 700-1200 m²/g

- Apparent Density: 320-550 kg/m³

- Activation Method: Steam/gas activation at high temperatures

- Pore Structure: Microporous-dominated, uniform pore distribution

- Environmental Profile: Chemical-free, low ash content

- Primary Applications: Gas-phase adsorption, drinking water purification

- Activation Method: Chemical activation (e.g., H₃PO₄/ZnCl₂) at moderate temperatures

- Pore Structure: Mesoporous-rich, higher surface area

- Process Efficiency: Shorter activation time, 30-50% higher yield

- Post-Treatment: Acid-washing required to remove residues

- Functionalization: Loaded with active agents (e.g., I₂/Ag/KOH)

- Targeted Adsorption: Enhanced capture of specific pollutants (e.g., Hg⁰/H₂S/acid gases)

- Customization: Chemically optimized for target contaminants

- Core Applications: Industrial gas treatment, CBRN protection

Benefits

Advanced Production Technology

Utilizes international leading activated carbon preparation technology, ensuring superior performance and consistent quality in honeycomb structures.

Versatile Applications

Ideal for various uses, particularly excelling in waste gas treatment and air purification processes.

Customizable Solutions

Offers personalized product solutions to meet specific customer needs, optimizing performance for unique applications.

Environmental Compliance

Meets international environmental standards (such as REACH, RoHS), supporting customers' environmental protection goals.

Strict Quality Control

Undergoes rigorous testing from raw material selection to finished product, ensuring compliance with national and international standards.

Enhanced Adsorption Efficiency

Unique honeycomb structure provides a large surface area and uniform channels, maximizing adsorption capacity and gas flow distribution.

Sustainable Development

Aligns with green environmental protection concepts, contributing to reduced environmental impact and supporting sustainable practices.

Applications

Gas Treatment

Water Treatment