Desiccant Applications

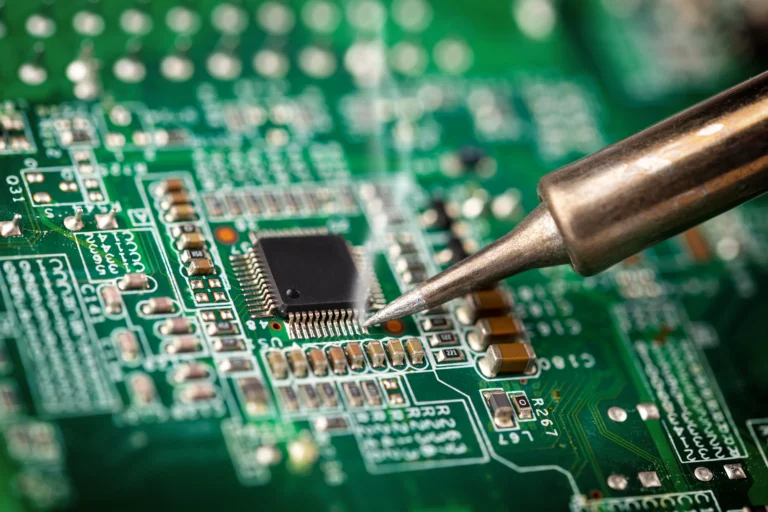

Desiccants are important components for ensuring product moisture protection during packaging, transport, and storage. In shipping and logistics desiccants are vital to protecting cargo, preventing corrosion, mold, and condensation in containers. In electronics, desiccants are used to protect sensitive components from failure, caused by environmental moistures, during transportation or long-term storage. In the food industry, desiccants can help to preserve shelf-life of packaged dry goods, spices, and snacks by preventing clumping, spoilage, and microbial growth.

Household desiccants (which often include hanging bags or boxes) help control dampness in closets, wardrobes, and storage places that protect clothing and textiles. Pharmaceuticals are happy users of desiccants in order to preserve the stability of drug products and comply with regulatory requirements for drug stability. In the automotive and military sectors, desiccants protect parts, equipment, and ammunition from corrosion. In construction, desiccants help to prevent moisture damage to building materials during storage and in sealed spaces (like insulation panels).

Related Blog