Automotive Desiccant

Buy Automotive Desiccant

Industry Challenges

Product Integrity & Safety

- Addressing risks of contamination, corrosion (especially from chlorides like CaCl₂/MgCl₂), dust release, and material compatibility with sensitive components (electronics, metals, optics).

Operational & Performance Demands

- Maintaining consistent moisture absorption efficiency under extreme conditions (temperature fluctuations, vibration, prolonged exposure) and achieving precise moisture control tailored to diverse component requirements.

Sustainability & Compliance

- Meeting strict environmental regulations (REACH/ELV), avoiding hazardous substances, reducing waste, and balancing recyclability/fiber-based options with traditional material performance.

Integration & Supply Chain Complexities

- Ensuring effective packaging integration (preventing rupture, enabling airflow), dust-free handling (esp. clays/powders), batch-to-batch quality consistency, and traceability across the supply chain.

Why Choose Our Desiccants

Engineered Material Safety

guarantees zero corrosive contamination risk to sensitive electronics and metals, eliminating component degradation concerns.

Optimized Performance Stability

delivers reliable moisture absorption under extreme automotive temperature ranges and vibration conditions.

Full Environmental Compliance

ensures adherence to REACH/ELV and hazardous substance restrictions while advancing sustainability initiatives.

Integrated Dust and Contamination Control

maintains optical clarity in headlights and upholstery integrity during interior dehumidification.

Application-Tailored Formulations

provide precise moisture control solutions for critical systems like airbags, ECUs, and fuel components.

Usage

Electronic Control Units (ECUs) and Sensors

Usage Overview

Desiccants are embedded in sealed ECU housings and sensor compartments to prevent moisture damage to circuitry during vehicle operation and storage.

Key Advantages

- Non-reactive silica gel maintains stable electrical properties without corroding contacts

- Fiber desiccants provide vibration-resistant moisture control without dust generation

- Molecular sieves ensure ultra-low humidity levels critical for microchip performance

- Corrosion-free protection extends component lifespan and prevents intermittent failures

Airbag Systems

Usage Overview

Desiccants are integrated into airbag modules and inflator assemblies to prevent humidity-induced degradation of pyrotechnic materials during long-term storage.

Key Advantages

- Stabilizes chemical propellants by maintaining critical moisture thresholds

- Montmorillonite and attapulgite provide reliable absorption at high temperatures

- Prevents false deployment signals caused by moisture-triggered circuit corrosion

- Ensures deployment reliability throughout the vehicle's operational lifespan

Headlight Assemblies

Usage Overview

Desiccant packets are installed inside headlamp and taillight assemblies to prevent fogging of optical surfaces during temperature fluctuations.

Key Advantages

- Silica gel and calcium chloride effectively prevent condensation on lenses

- Non-clouding absorption maintains optimal light transmission efficiency

- High moisture capacity prevents repeated fogging throughout seasonal changes

- Fiber-based options eliminate visible dust particles in the optical chamber

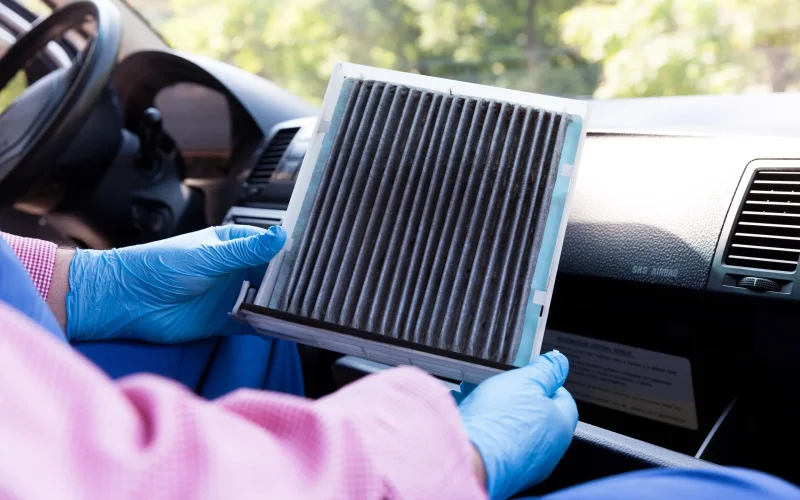

Vehicle Interior Dehumidification

Usage Overview

Rechargeable desiccant canisters or hanging packets actively absorb excess moisture from cabin air to maintain occupant comfort and prevent internal damage.

Key Advantages

- Removes musty odors caused by mold/mildew in upholstery and carpeting

- Prevents condensation on windshields and windows during humid conditions

- Protects in-cabin electronics (infotainment systems, displays) from humidity damage

- Preserves leather seat integrity by maintaining optimal humidity levels

- Calcium chloride and fiber desiccants offer rapid absorption without toxic emissions

Vehicle Shipping and Storage

Usage Overview

Desiccant units are placed inside cabin and cargo areas during ocean transit and long-term storage to prevent mold growth and metal corrosion.

Key Advantages

- Magnesium chloride and calcium chloride provide rapid humidity reduction

- Montmorillonite clay delivers sustained protection during multi-month transit

- Prevents musty odors and upholstery degradation in sealed environments

- Fiber desiccants absorb moisture without staining interior surfaces

- Maintains paint and trim integrity during humidity exposure

Fuel System Components

Usage Overview

Specialty desiccants protect fuel pumps, injectors, and tank sensors from moisture-related failures due to ethanol-blended fuels.

Key Advantages

- Prevents phase separation in ethanol-blended fuels by removing water

- Maintains lubricity in fuel pumps to prevent premature wear

- Reduces microbial growth in fuel tanks during seasonal storage

- Silica gel options won't contaminate fuel systems if packets rupture