Desiccant For Electronics

Buy Desiccant For Electornics

Desiccants in the electronics industry are broadly categorized in two ways: by the primary core desiccant material they are constructed with, and/or by their physical form/application method. The three main categories of desiccants include Silica Gel (high moisture capacity and high stability desiccant usually used for circuit boards and IC chips or packaged devices), Clay/Montmorillonite (low cost packaging solution for critical level packaging environments), and Composite (combination of desiccant materials for enhanced performance even if situations get moist or for sensitive SMT components). Forms include loose bulk desiccant (for bulk, large containers), desiccant bags (wire bai are par for the course for all electronics packaging), desiccant cards (flat products like displays), and desiccant canisters (sealed enclosure).

Industry Challenges

Material Compatibility & Purity

- Ensuring desiccants prevent contamination (e.g., chloride-induced corrosion from CaCl₂/MgCl₂, or dust from clay/mineral options like montmorillonite/diatomite) and meet stringent electronics cleanroom requirements.

Precision Humidity Control

- Meeting the ultra-low humidity thresholds demanded by miniaturized components and processes (e.g., preventing "popcorning" in SMT reels), requiring highly effective desiccants (e.g., silica gel, specialized composites) beyond basic clay/minerals.

Operational & Environmental Resilience

- Maintaining performance stability across the electronics supply chain's variable humidity/temperature conditions during global transit/storage, preventing premature saturation.

Physical Integration & Form Factor

- Designing desiccant solutions (e.g., slim fiber-based units, custom shapes) that fit within constrained packaging spaces without sacrificing capacity or introducing handling issues like dust.

Why Choose Our Desiccants

Engineered to prevent ionic contamination

And maintain material compatibility, especially critical for sensitive semiconductors and circuitry.

Precisely calibrated for demanding electronics environments

Meeting stringent moisture control requirements for applications like SMT reel protection.

Optimized physical formats minimize dust generation

And enable seamless integration, even in tightly packed devices like displays or optical components.

Delivers consistent, reliable performance across complex global supply chains

Maintaining protection through varying transit and storage conditions.

Offers tailored solutions

Using our diverse range (silica gel, CaCl₂, MgCl₂, montmorillonite, diatomite, fiber) for specific electronics challenges.

Usage

Silica Gel Desiccant For Transformer Breather

Usage Overview

Our silica gel desiccant is specifically engineered for transformer breathers to protect vital equipment from damaging moisture. The high-purity beads feature a vivid color indicator that changes from orange to green upon saturation, providing a clear, visual signal for maintenance.

Key Advantages

- Its performance is well-understood and trusted by industry professionals worldwide for critical transformer applications.

- It features a sharp and definitive color change from deep blue to vivid pink upon saturation.

- This minimizes breakdown and dust formation, which prevents clogging of the breather mesh and ensures consistent airflow for optimal long-term performance.

- This formulation provides a highly efficient and economical solution for protecting valuable transformer assets.

Related Products

Integrated Circuits (ICs) & Semiconductor Wafers

Usage Overview

Silica gel desiccants are predominantly used in hermetically sealed moisture barrier bags to protect bare dies and wafers during storage and transit.

Key Advantages

- High Purity Protection: Prevents ionic contamination critical for semiconductor integrity

- Chemically Inert: Will not react with sensitive metallization layers

- Low Dust Emission: Maintains cleanroom standards during handling

- Precise Humidity Control: Maintains ultra-low RH levels to prevent oxidation

Printed Circuit Board Assemblies (PCBAs)

Usage Overview

Montmorillonite clay desiccants are embedded in SMT reel packaging to protect exposed copper traces before soldering, while fiber-based desiccants shield assembled boards during shipping.

Key Advantages

- Vibration Resistance: Clay desiccants remain intact during reel transport

- Conformability: Fiber desiccants contour around components without stress

- Dust-Free: Fiber variants eliminate particulate contamination risk

- Rapid Moisture Lock: Prevents "popcorning" during reflow soldering

Consumer Electronics (Smartphones/Laptops)

Usage Overview

Silica gel packets and diatomite desiccants are placed inside product boxes to prevent condensation during global shipping, while calcium chloride units protect devices in tropical warehouses.

Key Advantages

- Non-Toxic Safety: Silica gel poses no risk if accidentally contacted

- High Capacity Absorption: Calcium chloride handles humidity spikes in containers

- Space-Efficient: Diatomite variants fit behind batteries and screens

- Corrosion Prevention: Protects connectors and metal components

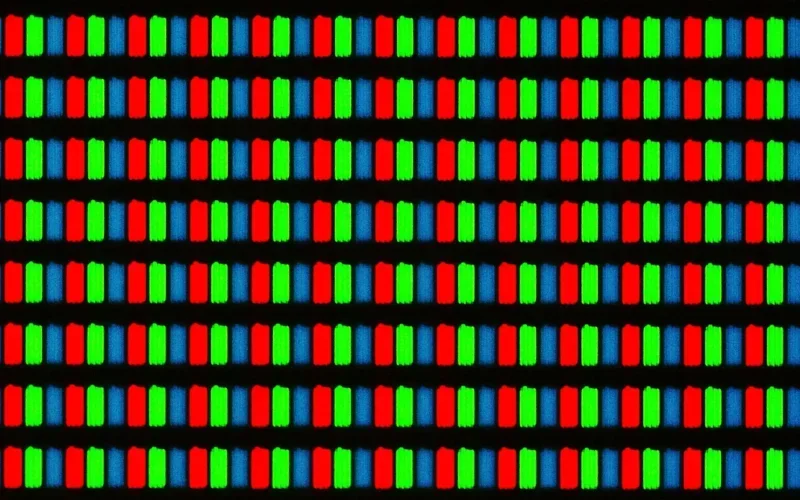

Display Panels (LCD/OLED)

Usage Overview

Magnesium chloride composite cards are laminated between panel layers to absorb outgassing moisture during manufacturing, while fiber desiccants line protective films.

Key Advantages

- Anti-Outgassing: Magnesium chloride combats moisture release from adhesives

- Delamination Prevention: Maintains bonding integrity of optical layers

- Ultra-Thin Profile: Fiber desiccants integrate invisibly into displays

- Mura Defect Reduction: Prevents humidity-induced image distortion

Optical Components (Lenses/Sensors)

Usage Overview

Magnesium chloride or silica gel canisters are sealed within optical device housings (e.g., cameras, LiDAR) to maintain dry internal environments during operation and storage.

Key Advantages

- Fog Prevention: Eliminates internal lens condensation

- VOC Adsorption: Composites reduce haze-causing volatiles

- Corrosion Resistance: Protects delicate mirror coatings

- Long-Term Stability: Performs consistently across temperature cycles

FAQ

All-in-One Solution

Find all the tools you’ll need to create advanced websites in one place. Stop waisting time searching for solutions.

Advanced Tools

Add more power to Elementor using our creative elements and make your projects look prettier than ever before.

Nonstop Updates

We strive to innovate when it comes to functionality. Our mission is to be the best, come and join the ride.

24/7 Dedicated Support

Each and every one of our customers receives personalised assistance from our dedicated support team.