Food Desiccant

Buy Food Desiccant

Industry Challenges

Food Safety & Regulatory Compliance

- Ensuring non-toxic, food-grade materials meeting stringent global regulations (e.g., FDA, EU).

- Preventing chemical migration or contamination from desiccants to food products.

Product Integrity & Performance

- Maintaining physical integrity (no rupture/leakage) throughout harsh supply chains.

- Balancing material limitations (absorption capacity/rate, environment suitability) for specific food types/applications.

- Achieving necessary performance while meeting safety and space constraints.

Packaging Integration & User Safety

- Designing for seamless incorporation within diverse packaging formats without compromising function.

- Preventing accidental consumer ingestion/misuse through clear labeling and robust design.

- Maintaining packaging integrity and consumer appeal.

Sustainability Evolution

- Addressing pressure to develop eco-friendly solutions (biodegradable/recyclable materials, reusable formats).

- Reducing environmental footprint without sacrificing essential safety or performance standards.

Why Choose Our Desiccants

Food Safety Certified Materials

All products strictly comply with global food-grade standards for direct and indirect contact applications.

Enhanced Moisture Protection

Engineered for superior absorption efficiency across varying storage conditions and food types.

Product Integrity Assurance

Robust packaging prevents desiccant leakage while maintaining physical integrity throughout supply chains.

Sustainable Design Options

Available formats minimize environmental footprint without compromising performance requirements.

Technical Application Support

Tailored selection guidance ensures optimal performance for specific product moisture sensitivity profiles.

Usage

Packaged Dry Snacks & Cereals

Usage Overview

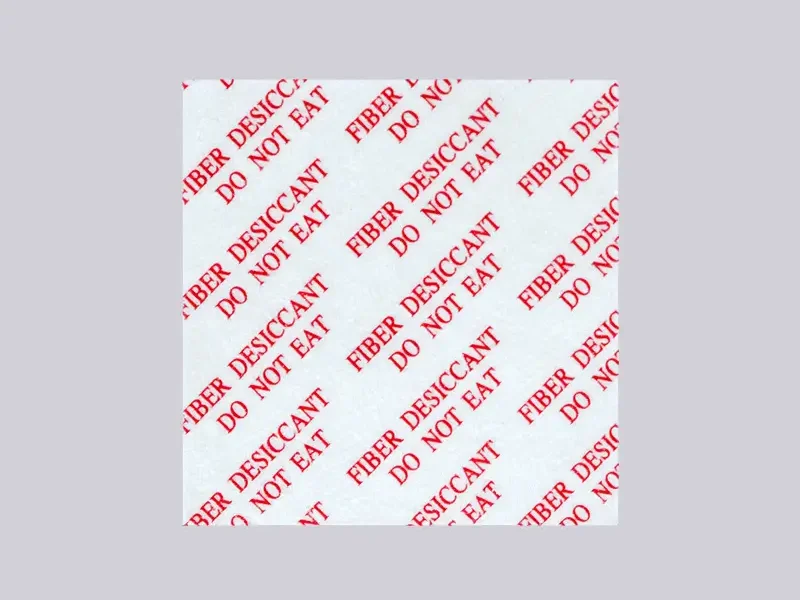

Silica gel or fiber desiccant sachets are inserted into bags/boxes of chips, crackers, and cereals to maintain crispness during storage and distribution.

Key Advantages

- Silica gel prevents texture degradation by absorbing ambient moisture

- Fiber desiccant offers high transparency for consumer visibility

- Maintains seasoning adhesion and prevents clumping

- Minimizes staleness without altering food flavor

Baked Goods & Confectionery

Usage Overview

Montmorillonite (clay) desiccant canisters or fiber packets are placed in bread, cake, and candy packaging to control surface moisture.

Key Advantages

- Montmorillonite effectively controls sugar crystallization in chocolates

- Prevents hardening of gummies and soft candies

- Inhibits mold growth on moisture-rich baked goods

- Fiber desiccant provides lint-free protection for delicate items

Spices & Powdered Ingredients

Usage Overview

Attapulgite (clay mineral) or silica gel packets are embedded in spice jars and powder packaging to prevent moisture absorption during storage.

Key Advantages

- Attapulgite maintains flowability in hygroscopic powders

- Prevents caking and clumping of salt/sugar crystals

- Preserves volatile flavor compounds in herbs

- Silica gel protects moisture-sensitive functional ingredients

Dried Meats & Jerky

Usage Overview

Silica gel and montmorillonite desiccants are used in jerky packaging to maintain controlled moisture levels during shelf life.

Key Advantages

- Maintains desired chewiness without overdrying

- Prevents bacterial growth in protein-rich products

- Extends product stability without preservatives

- Preserves flavor integrity during temperature fluctuations

Premium Tea & Coffee

Usage Overview

Fiber desiccants or specialty silica gel packets are used in coffee bags and tea canisters to preserve aromatic compounds.

Key Advantages

- Fiber material prevents flavor contamination

- Maintains precise moisture equilibrium

- Protects delicate volatile oils from degradation

- Lint-free performance for ground products

Bulk Commodity Storage

Usage Overview

Calcium chloride or magnesium chloride units are hung in shipping containers and silos for grains, coffee, or frozen foods during transit.

Key Advantages

- Controls condensation during temperature changes

- Prevents mold formation in high-humidity environments

- Deliquescent properties absorb liquid moisture

- High-capacity protection for extended transit times

FAQ

Packaging & Transportation Desiccant

Silica gel desiccants are necessary to protect products in transit and storage. Silica gel desiccants are packaged in breathable sachets or canisters, and manage humidity in shipping containers, cartons, and crates. Silica gel absorbs moisture in the ambient air, and prevents condensation, mold, metal corrosion, and damage to moisture sensitive materials. Silica gel is perfect for electronics, machinery, art, and paper products, to ensure items arrive in the right condition no matter what climate change may have occurred during the logistics of global transport.

Electronics Industry

Silica gel is well known for its moisture control properties in electronic manufacturing and storage. Proper protection of sensitive components is critical, especially in packaging of items such as circuit boards, semiconductors, or optical devices. By using silica gel in sealed packages, or sealed cabinets, electronics are kept in low-humidity environments. This reduces the risks of unforeseen damage to components from oxidation, electrical shorts, and performance failures of any kind. The properties of silica gel, non-corrosive, dust-free, and safe for direct contact with delicates parts, ensures safe shipping and handling from factoryels in an unopened condition.

Pharmaceutical Industry

Silica gel provides vital moisture prevention in medicine bottles, diagnostic kits and as a component of medical device packaging. Silica gel satisfies FDA and pharmacopeia requirements and protects tablets, capsules, and laboratory reagents from both moisture-driven degradation and elevated moisture levels. Importantly, silica gel acts to stabilize humidity levels in sealed environments extending shelf-life, sterility, and therapeutic effectiveness or viability. Silica gel packets not only work well to smooth out humidity changes, but they are also transparent which allows a visual inspection. Furthermore, cobalt-free silica gel packets pose no toxicity issues in deliberately sensitive applications.

Food Industry

Silica gel provides vital moisture prevention in medicine bottles, diagnostic kits and as a component of medical device packaging. Silica gel satisfies FDA and pharmacopeia requirements and protects tablets, capsules, and laboratory reagents from both moisture-driven degradation and elevated moisture levels. Importantly, silica gel acts to stabilize humidity levels in sealed environments extending shelf-life, sterility, and therapeutic effectiveness or viability. Silica gel packets not only work well to smooth out humidity changes, but they are also transparent which allows a visual inspection. Furthermore, cobalt-free silica gel packets pose no toxicity issues in deliberately sensitive applications.

Related Blog