Fiber Desiccant

Buy Fiber Desiccant

Fiber desiccant is an eco-friendly, moisture absorbing material consisting of cellulose fibers derived from plants, with a high capacity for adsorption up to 100% of its weight in a thin and flexible form. Because of the porous structure of the fibers, fiber desiccant has rapid humidity control and very efficient space utilization for its size, making it ideal for narrow spaces where traditional desiccants might not fit. Fiber desiccant is also non-toxic, all-natural, and biodegradable, compliant with the FDA, EU, and direct food contact regulations (i.e. 21 CFR 176.170) and has a very low dust release; thereby, it can protect sensitive products when also providing desiccant protection.

Applications of Fiber Desiccant

Fiber desiccant is a fantastic choice for many food-contact applications because of its cellulose-based material that is FDA compliant. It can be made into ultra-thin sheets or unique shapes and can be inserted into snack bags, spice jars, or supplement bottles to absorb moisture to reduce clumping and spoilage. Fiber desiccant has a superior absorbency rate (100% of its weight), and it will keep foods like chips, crackers, and dried fruits crispy without dealing with chemical migration. And unlike white silica gel (which is not biodegradable), fiber desiccant fits very well with sustainable packaging ideals, with a biodegradable material that provides compostable protection in compliance with EU Regulation 10/2011 and FDA (21 CFR 176.170 ) compliance. Fiber desiccant is especially appropriate for clean-label options, and works well with organic products, since it helps prevent mold growth while maintaining the integrity of flavor during distribution.

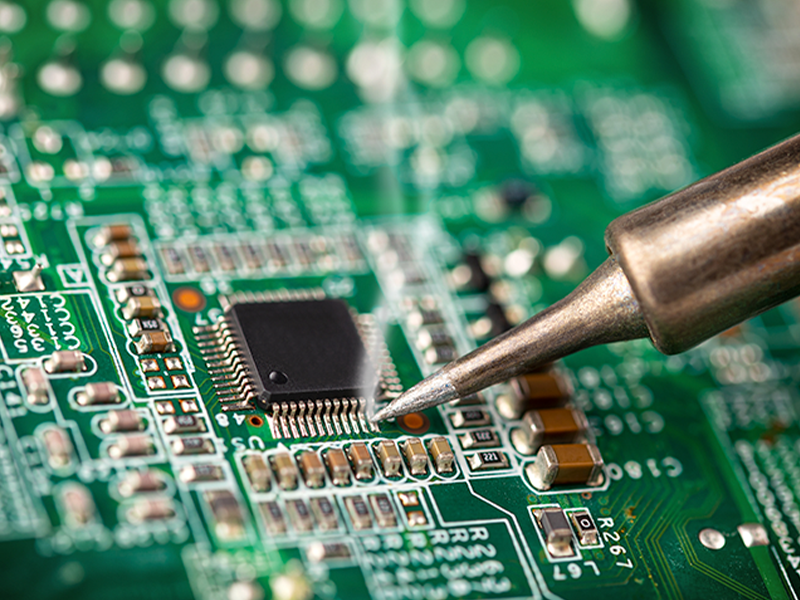

This ultra-slim desiccant can be used to protect sensitive electronics and can fit into very space constrained packaging. It has an ultra-slim profile (0.3-1mm thickness) to fit underneath the screen of a smartphone, inside the camera module of a cell phone, and inside a tray of microchips where traditional desiccants cannot fit. Made up of non-dusting cellulose fibers, the desiccants will not leave particles on circuit boards, and will rapidly adsorb any moisture to protect against condensation damage, especially during global shipping. Some versions are ESD safe to protect against static discharge, and custom die cut shapes can be designed to fit specific product geometries. The ultra-slim desiccant is particularly important in consumer electronics, medical device and semiconductor packaging that requires humidity control without added thickness and weight.

Pharmaceutical Industry

Fiber desiccant is a necessary moisture protection part of medical device packaging. The use of Fiber desiccant complies with test procedures in USP <671> and ISO 11607. Fiber desiccant maintains sterility for AML blister packs, diagnostic kits, and surgical instrument trays. The cellulose fiber material is non-linting and does not generate particulate, providing cleanroom compliant conditions. Fiber desiccant has high moisture absorption capacity, ensuring drug stability. Fiber desiccant can be produced and packed in ultra-thin formats that can be added within pill bottles and do not affect contemplated dose volume. The cellulose fiber desiccant composition is biocompatible and can be put in direct contact with implants. Custom die-cut shapes can be made to match device geometry, plus, Fiber desiccants can be produced and sterilized using gamma rays. Fiber desiccants are an essential moisture control component for temperature sensitive biologics and hygroscopic medications that require precise humidity control.

Apparel & Textiles

The fiber desiccant is perfect for protecting luxury apparel and footwear against mildew without diminishing their presentational qualities. When sewn into folded garments or the linings of shoes, fiber desiccant is only 0.5mm thick, and it will not be visible while absorbing moisture during transport and storage. The cellulose fibers are natural and absorb moisture odorlessly, making them ideal for silks, leathers, and wools. The cellulose fibres are safe and will not bleed dyes, and cellulose is also biodegradable, so it’s also accepted under the sustainable fashion umbrella. Fiber desiccant can be custom cut to fit handbag pockets or hat boxes. The product can be reactivated and reused, which is a great sustainable way to prevent mold growth on valuable couture or vintage textiles, and when you’re storing seasonal goods without the hassle of bulk.

Automotive Industry

Moisture-sensitive precision components in space-limited automotive environments require protection, specifically from water condensation. The polyfiber desiccant is die-cut to match the geometry of sensor housings, ECU modules, infotainment systems, and other confined spaces. It prevents electrical failures due to moisture condensation, during storage or transporting in an enclosed space. The very thin (≤1mm) profile is located behind the dash assembly or integrated into headlamp assembly without interfering with other electronic components. Additionally, there are ESD-safe versions available to protect other types of sensitive circuitry and components. The related temperature performance is -40°C to 100°C, for applications from arctic (or sub-arctic) testing to transport in the extreme heat of the desert. The non-corrosive nature of the fiber desiccant includes vibration resistance, and allows for the expansion of component life by controlling micro-environments in hybrid and electric vehicles where moisture damage risks are greater.

Why you choose us

Space-Efficient Protection

Ultra-thin design (0.3-1mm) fits seamlessly in confined spaces where traditional desiccants cannot be used.

Direct Food/Pharma Compliance

FDA, EU, and RoHS certified for direct contact with food, pharmaceuticals, and electronics ensuring non-toxic protection.

Eco-Conscious Performance

100% biodegradable plant-based cellulose with compostable disposal aligns with sustainability goals.

Precision Customization

Die-cut to exact specifications for unique enclosures in electronics, medical devices, and luxury goods.

Contamination-Free Operation

Dust-free and non-linting properties protect sensitive components in cleanrooms and precision assemblies.

Related Blog

Compare fiber desiccant and silica gel desiccant for moisture control, safety, cost, and eco-friendliness...

Fiber desiccant offers superior moisture absorption, eco-friendly materials, and safe use for food, medicine,...

No posts found