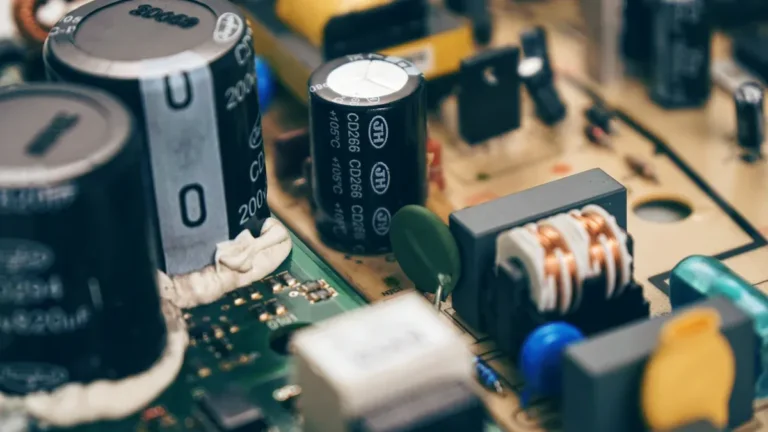

Condensador de carbón superactivado

.webp)

Buy Super Capacitor Activated Carbon

Industry Challenges for Activated Carbon in Supercapacitors

Energy Density Limits

- AC offers terrific power density and long cycle life but has an inevitable disadvantage in storing less energy per unit volume/weight than battery technologies. Therefore, increasing energy density without diminishing power or lifetime constraint is indeed challenging.

Consistency & Sourcing

- Achieving reproducibility in AC properties throughout a large batch (surface area, pore structure distribution) from precursor materials that are derived from nature can be quite difficult. Deviations in batch variations will affect the predictability of the voltage response and cannot be assumed the same.

Electrode Processing and Fabrication

- The complexity of integrating high-surface-area AC powders into structurally robust and conductive electrodes with acceptable accessibility of enough electrolyte, involves complex slurry processing and coating techniques. It is also difficult to ensure sufficient adhesion in an electrode with a large thickness, as well as avoiding cracking.

Performance Compromises

- Often, optimizing pore size for maximal ion movement (power), conflicts with maximizing surface area in order to maximize charge storage (energy). Striking a compromise between the two competing designs for specific applications is not a trivial exercise.

Environmental & Processing Implications

- When producing high-performance AC, the synthesis often involves energy-intensive processes or use of environmental contaminants. Managing waste streams from AC production processes, and developing true sustainable, scalable production routes from waste products are significant ongoing implications.

Recyclability

- Recovering and reusing AC out of end-of-life supercapacitors is complicated by logistical and technical challenges.

tipos de carbón activado relacionados

-r8fslg51nt6wgjtvh6yldxb1gtkgm3lpe0oq1akgog.webp)

- Valor de yodo: 600-1200

- Tamaño de malla: 1×4/4×8/8×16/8×30/12×40/20×40/20×50/30×60/40×70 (Más tamaños a petición)

- Densidad aparente: 400-700

-r8fsli0q1h9h3rr567ruiwtynlb71ht629zozuhoc0.webp)

- Valor de yodo: 500-1300

- Tamaño de malla:0,9-1mm/1,5-2mm/3-4mm/6mm/8mm(Más tamaños a petición)

- Densidad aparente: 450-600

-r8fslbfupn0gui0p8mxgjghqhw7mjm31pdfamwrfjk.webp)

- Valor de yodo: 500-1300

- Luz de malla: 150/200/300/350 (Más luces a petición)

- Densidad aparente: 450 - 550

-r8fsle9da54btbwls65c8xs4a1tq6pe8prdr2qn90w.webp)

- Valor de yodo: 400-800

- Tamaño de malla: 100×100×100 mm/100×100×50 mm (densidad celular personalizada bajo pedido)

- Densidad aparente: 350-450

- Diámetro interior:1,5-8 mm

- Valor de yodo: 700-1200 mg/g

- Superficie 700-1200 m²/g

- Densidad aparente: 320-550 kg/m³

- Valor de yodo: 700-1200 mg/g

- Superficie 700-1200 m²/g

- Densidad aparente: 320-550 kg/m³

- Valor de yodo: 700-1200 mg/g

- Superficie 700-1200 m²/g

- Densidad aparente: 300-650 kg/m³

- Valor de yodo: 700-1200 mg/g

- Superficie 700-1200 m²/g

- Densidad aparente: 320-550 kg/m³

- Método de activación: Activación por vapor/gas a altas temperaturas

- Estructura de los poros: Microporosa-dominada, distribución uniforme de los poros.

- Perfil medioambiental: Sin productos químicos, bajo contenido en cenizas

- Aplicaciones principales: Adsorción en fase gaseosa, purificación de agua potable

- Método de activación: Activación química (por ejemplo, H₃PO₄/ZnCl₂) a temperaturas moderadas.

- Estructura de los poros: Mesoporoso-rico, mayor área superficial

- Eficiencia del proceso: Menor tiempo de activación, mayor rendimiento 30-50%

- Tratamiento posterior: Lavado con ácido para eliminar residuos

- Funcionalización: Cargado con agentes activos (por ejemplo, I₂/Ag/KOH).

- Adsorción selectiva: Captura mejorada de contaminantes específicos (por ejemplo, Hg⁰/H₂S/gases ácidos).

- Personalización: Químicamente optimizado para los contaminantes objetivo

- Aplicaciones principales: Tratamiento de gases industriales, protección QBRN

Por qué utilizar nuestro carbón activado

Exceptional Material Consistency:

Our stringent manufacturing controls guarantee the uniformity of surface area, pore size distribution, and particle morphology from batch-to-batch. As a result, we offer predictable electrode performance, and easier integration into existing manufacturing systems.

Enhanced Electrochemical Performance:

Our engineered dual hierarchical porosity (micro-meso-macro pores) maximize the ion-accessible surface area while supporting fast ion diffusion, providing our electrodes with very high power density and energy density.

Improved Long-Term Stability:

By using advanced surface purification, we minimize the unstable oxygen functional groups and metallic impurities on our surface to minimize gas evolution during cycling, thus improving device lifetime, and operational safety.

Customized Application Solutions:

Our surface chemistry and pore structures can be tuned and customized for specific electrolyte compatibility and to target performance measures (e.g., high power vs. high energy focus).

Sustainable and Scalable Copying Supply:

We use reliable precursors and optimized activation conditions to ensure our practice is environmentally responsible and offers reliable quality at scale and reasonable costs.

Proceso y tecnología

1. Primary Electrode Material in EDLC Supercapacitors

Resumen de la solución

Upon AC electrodes, charge is stored physically due to the mechanism of ion adsorption at the electrode/electrolyte interface. AC electrodes have high surface area and tunable pore subnetworks (micro/mesopores) which could help with the number of accessible ions as well as the overall charge storage capacity.

Principales ventajas

- High surface area enables massive charge storage capacity through double-layer formation.

- Rapid ion adsorption/desorption supports ultrafast charge/discharge cycles and high power density.

- Physical charge storage ensures exceptional cycling stability and longevity.

- Broad operating temperature range suits diverse environmental conditions.

2. Biomass-Derived Sustainable Electrodes

Resumen de la solución

Biomass precursors undergo carbonization and chemical activation (e.g., KOH, self-activation) to produce AC with tailored pore hierarchies and heteroatom doping (O, N). This enhances conductivity and pseudocapacitance.

Principales ventajas

- Waste valorization reduces environmental impact and raw material costs.

- Self-doped heteroatoms (e.g., N/O from biomass) improve wettability and introduce pseudocapacitance.

- Hierarchical pores (macro/meso/micropores) facilitate ion buffering and rapid diffusion.

- Lower activation temperatures in some methods reduce energy consumption.

3. Composite Electrodes with Transition Metal Hydroxides

Resumen de la solución

AC acts as a conductive scaffold for metal hydroxides, mitigating their poor conductivity and stacking issues. The composite leverages both double-layer capacitance (AC) and reversible faradaic reactions (hydroxides).

Principales ventajas

- Energy density boost via combined charge storage mechanisms.

- Enhanced conductivity from the AC framework enables efficient electron transport.

- Suppressed electrode stacking exposes more active sites for redox reactions.

- Improved cycle life due to structural stability from AC support.

4. Post-Filling for High Volumetric Performance

Resumen de la solución

Macro/mesopores in AC are filled with carbonizable agents (e.g., tannic acid), followed by carbonization. This increases density while preserving microporous charge storage sites.

Principales ventajas

- Higher electrode density elevates volumetric capacity without sacrificing porosity.

- Retained rate capability ensures performance under high current loads.

- Optimized pore utilization balances ion diffusion and charge storage.

5. Surface Functional Group Engineering for Gas Suppression

Resumen de la solución

High-temperature treatment removes surface groups (e.g., carboxyl, quinone). Mixed-acid purification further reduces impurities (e.g., Fe), minimizing gas generation.

Principales ventajas

- Reduced gas evolution extends device lifespan and safety.

- Higher purity lowers internal resistance and improves conductivity.

- Stabilized electrochemical interface enhances cycling reliability.