Utiliza Carbón activado para biogás para capturar las sustancias nocivas del biogás antes de que llegue a sus máquinas. Este paso se denomina purificación del biogás. Mantiene los motores seguros y mejora el combustible. El biogás bruto contiene sustancias como sulfuro de hidrógeno, amoníaco, siloxanos y compuestos orgánicos volátiles. Estas cosas pueden oxidar o dañar su equipo.

Eliminar estos elementos nocivos hace que su sistema sea más seguro y ayuda a que funcione mejor.

Principales conclusiones

La limpieza del biogás es importante para eliminar elementos nocivos como el sulfuro de hidrógeno y el amoníaco. De este modo, las máquinas son más seguras y aprovechan mejor la energía.

Elegir el carbón activo adecuado es muy importante. Algunos tipos funcionan mejor para ciertas cosas malas, así que elija el carbón que se adapte a su biogás.

Comprobar y cambiar los filtros de carbón activado a menudo. Si percibe malos olores o los filtros le resultan pesados, significa que debe cambiarlos. Así mantendrá su sistema funcionando bien.

El uso de dos filtros permite que su sistema siga funcionando. Un filtro puede funcionar mientras usted cambia el otro. Esto significa que su sistema no tiene que detenerse.

Un buen mantenimiento, como la búsqueda de fugas y la comprobación del flujo de gas, mantiene la seguridad y el buen funcionamiento del sistema de biogás.

Conceptos básicos de la purificación del biogás

Por qué purificar el biogás

Debes biogás limpio antes de utilizarlo en motores o calderas. Purificar el biogás le ayuda a obtener más energía de él. También mantiene sus máquinas a salvo de daños. La eliminación de sustancias nocivas hace que el gas sea bueno para diferentes máquinas. Si no depura el gas, sus equipos pueden resultar dañados. El sulfuro de hidrógeno puede oxidar las piezas metálicas. El gas sucio puede hacer que los motores funcionen mal. También puede tener problemas con el funcionamiento de sus máquinas.

Consejo: Limpiar el biogás le ayuda a cumplir las leyes de seguridad. Muchos lugares tienen normas para el metano, las impurezas y el agua en el biogás. Es necesario eliminar el agua y las sustancias nocivas, como el sulfuro de hidrógeno y los compuestos orgánicos volátiles, para cumplir estas normas.

He aquí las principales razones para limpiar el biogás:

Mantenga la seguridad de motores, calderas y vehículos

Asegúrate de que el gas sirve para muchos usos

Si te saltas la limpieza del biogás, podrías tener:

Mala calidad del gas y escaso rendimiento

Problemas para que los motores funcionen con suavidad

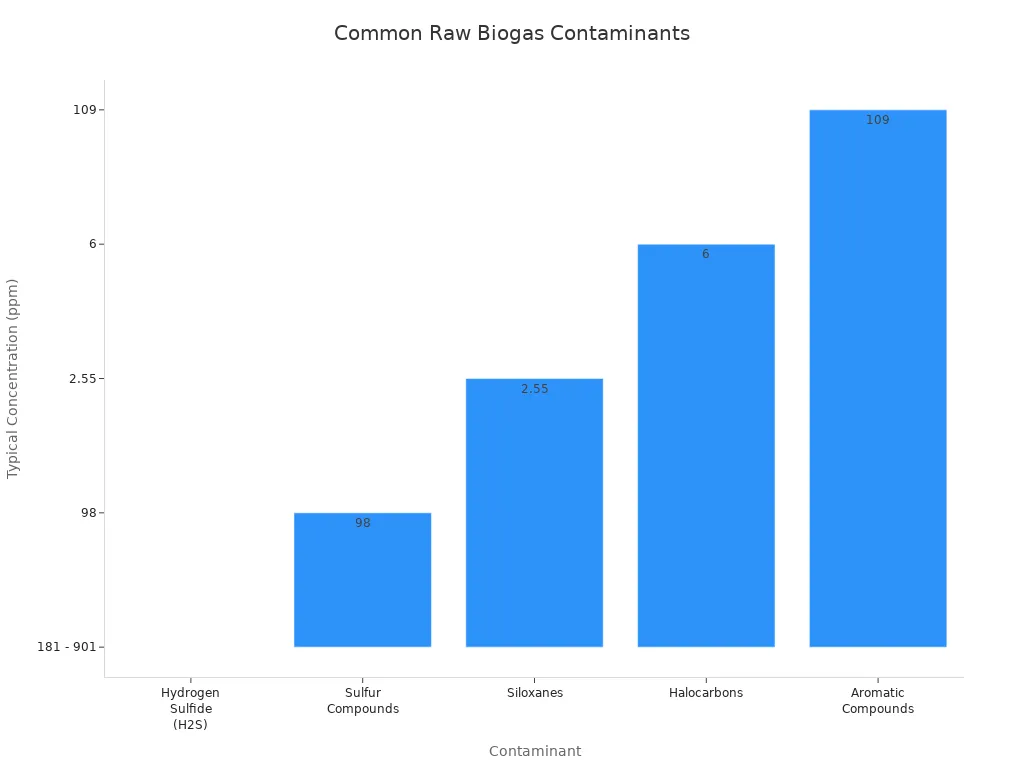

Contaminantes comunes

El biogás es principalmente metano y dióxido de carbono. También contiene pequeñas cantidades de sulfuro de hidrógeno, amoniaco, siloxanos y compuestos orgánicos volátiles. El sulfuro de hidrógeno es muy peligroso. Es venenoso y puede dañar sus máquinas. El La Junta de Recursos del Aire de California dice estas cosas malas puede producir sustancias tóxicas al quemar biogás. Esto puede dañar tus máquinas y contaminar el aire.

Contaminante | Riesgo para los equipos | ¿Por qué eliminar? |

|---|---|---|

Sulfuro de hidrógeno | Corrosión, toxicidad | Proteger los motores, la seguridad |

Amoníaco | Suciedad, olores | Mejorar la calidad del aire |

Siloxanos | Depósitos duros | Evitar daños en el motor |

COV | Contaminación, olores | Cumplir las normas de emisiones |

Agua/humedad | Óxido, mala combustión | Garantizar la eficacia |

Es necesario limpiar el biogás para deshacerse de estas sustancias nocivas. Los grupos de seguridad comprueban si se cumplen las normas para un uso seguro. Hoy en día es habitual mejorar el biogás para cumplir las normas del biometano.

Tipos de carbón activado para biogás

Criterios de selección

Cuando elija carbón activado para biogás, debe pensar en algunas cosas. El tipo de carbón activado que elija cambia la eficacia con la que limpia el biogás. Cada tipo tiene su propia capacidad de adsorción, superficie y densidad. Es necesario adaptar el carbón adecuado a las sustancias nocivas del biogás.

A continuación se muestra una tabla con algunos tipos comunes de carbón activado para biogás y cómo son:

Tipo de carbón activado | Índice de yodo (mg/g) | Superficie (m²/g) | Densidad aparente (kg/m³) |

|---|---|---|---|

Carbón activado de cáscara de nuez | 700-1200 | 700-1200 | 320-550 |

Carbón activado a base de carbón | 700-1200 | 700-1200 | 300-650 |

Carbón activado a base de madera | 700-1200 | 700-1200 | 320-550 |

Carbón activado granular (CAG) | 600-1200 | N/A | 400-700 |

Carbón activado granulado | 500-1300 | N/A | 450-600 |

Carbón activado en polvo | 500-1300 | N/A | 450-550 |

Carbón activado en forma de panal | 400-800 | N/A | 350-450 |

Carbón activado de cáscara de coco | 700-1200 | 700-1200 | 320-550 |

También deberías fijarte en estas cosas:

El tipo de carbón activado para biogás (en polvo, granulado, peletizado)

Los contaminantes exactos que desea eliminar

La temperatura, la presión y la humedad del lugar donde se utiliza

Cuánto tiempo quiere que dure el carbón antes de cambiarlo

La fuerza de los grandes sistemas

El tamaño de los poros del carbón activado para biogás es muy importante. Los poros ayudan a atrapar las sustancias nocivas por adsorción. Las superficies más grandes y los tamaños de poro adecuados ayudan a que el carbono funcione mejor. Por ejemplo, el sulfuro de hidrógeno se elimina mejor con carbones que tienen muchos mesoporos y microporos. Esta configuración ayuda a atrapar más contaminantes y hace que el filtro dure más.

Consejo: El carbón activo granulado es resistente y funciona bien para limpiar biogás todo el tiempo. El carbón en polvo funciona rápido, pero puede que tengas que cambiarlo más a menudo.

Aplicación en sistemas de biogás

Para limpiar el biogás se utiliza carbón activo de diferentes formas. El carbón activo granulado se utiliza mucho para eliminar compuestos orgánicos volátiles. El carbón granulado proporciona un buen tiempo de contacto y no ralentiza mucho el gas. Algunos carbones se fabrican para captar el sulfuro de hidrógeno y el amoníaco.

Tipo de carbón activado | Descripción de la aplicación |

|---|---|

Carbón activado granular (CAG) | Elimina bien los COV para limpiar siempre el biogás. |

Pellets extruidos | Proporciona una buena presión y tiempo de contacto para la limpieza con gas. |

Grados impregnados | Hecho para atrapar cosas como H₂S y NH₃. |

Se colocan filtros de carbón activado de biogás en la línea de gas después de que el biogás bruto salga del digestor. El gas pasa por el lecho de carbono. Los contaminantes se adhieren al carbón por adsorción. El carbón activado para biogás puede capturar más contaminantes que otros elementos como la sílice o las zeolitas. Se consigue una mejor eliminación del sulfuro de hidrógeno, el dióxido de carbono y otras impurezas.

El carbón activado para biogás no cuesta mucho. Le ayuda a ahorrar dinero, sobre todo si su planta está en un lugar que no dispone de mucho dinero. Puede utilizar otros materiales baratos, pero el carbón activado para biogás le ofrece la mejor combinación de poder de limpieza, precio y flexibilidad.

Nota: La eficacia de la adsorción depende del tipo de carbón, del tamaño de los poros y de cómo se utilice. Compruebe siempre qué necesita su sistema antes de elegir su carbón activo para biogás.

Desulfuración de biogás y eliminación de contaminantes

Eliminación de sulfuro de hidrógeno (H2S)

Debe eliminar el sulfuro de hidrógeno del biogás. Esto se debe a que el sulfuro de hidrógeno es muy perjudicial. Puede oxidar las piezas metálicas y romper los motores. También puede causar problemas de seguridad. Si no elimina el sulfuro de hidrógeno, la combustión del gas puede producir humo tóxico. Eliminarlo mantiene sus máquinas seguras y le ayuda a cumplir las normas del aire.

El carbón activado se utiliza para eliminar el h2s. Esto funciona tanto para sistemas de biogás grandes como pequeños. La separación del H2S se produce cuando el gas atraviesa el carbón activado. El carbón agarra el H2S y lo retiene en su superficie. Algunos carbones activados pueden incluso convertir el H2S en azufre seguro.

He aquí cómo el carbón activado elimina el H2S del biogás:

Tipo de mecanismo | Descripción |

|---|---|

Adsorción física | El carbono retiene el H2S en su superficie con fuerzas débiles. |

Reacciones químicas | El carbono transforma el H2S en azufre por oxidación. |

Se puede mejorar la adsorción de h2s utilizando productos químicos especiales. El yoduro de potasio ayuda a convertir el H2S en azufre sólido. Por ejemplo, el carbón activado impregnado de KI utiliza esta reacción:H2S + ½ O2 → S + H2O

Esta reacción le ayuda a obtener mejores resultados.

Puede conseguir altos índices de eliminación con los pasos adecuados. Por ejemplo:

El biocarbón en astillas puede eliminar más de 98% de H2S.

El carbón activado fabricado a 450°C y activado a 750°C puede retener unos 98 mg de H2S por gramo.

La separación del H2S funciona mejor si se controla la humedad y el pH. Una humedad elevada y un pH cercano a 8 favorecen el proceso. El uso de carbón activado con óxidos metálicos, como el potasio o el hierro, puede hacer que la adsorción de h2s sea aún mejor.

Consejo: Compruebe siempre el carbón activado. Cuando se llene de azufre, deberá cambiarlo o limpiarlo. Esto mantiene su desulfuración de biogás funcionando bien.

COV, siloxanos y otras impurezas

También hay que eliminar otros elementos nocivos del biogás. Se trata de compuestos orgánicos volátiles, siloxanos, amoníaco y, a veces, dióxido de carbono. Cada uno de ellos puede dañar sus máquinas o el medio ambiente.

El carbón activado ayuda a eliminar estas impurezas. Funciona atrapando las moléculas en su superficie. En el caso de los siloxanos, el carbón activo puede atraparlos antes de que lleguen a los motores. Los estudios demuestran que el carbón activado comercial puede eliminar los siloxanos como el D4 muy bien. Incluso puede limpiar el carbono y volver a utilizarlo. El uso de hierro con oxidación avanzada le ayuda a recuperar el carbono.

El amoníaco y los COV también se adhieren al carbón activado durante la separación del h2s. La eliminación de estas impurezas mantiene su gas limpio y protege sus máquinas. Si su biogás tiene muchas impurezas, es posible que necesite carbón activado especial o añadir óxidos metálicos para ayudarle.

Aquí hay una tabla que muestra lo que afecta a la adsorción de H2S y otras impurezas:

Principales resultados | Descripción |

|---|---|

Influencia de los óxidos metálicos | Los óxidos metálicos como el potasio, el hierro y el cobre ayudan a eliminar mejor el H2S. |

Quimisorción frente a fisisorción | La quimisorción funciona mejor para el azufre que la fisisorción. |

Superficie y volumen de poros | Más superficie y poros más grandes significan mejor adsorción. |

Si tiene muchas impurezas, es posible que su carbón activado no funcione tan bien. Mucho H2S, COV y siloxanos juntos significan que debe comprobar su carbón más a menudo. Es posible que tenga que sustituirlo más rápidamente.

Nota: Una buena desulfuración del biogás y la eliminación de impurezas le ayudan a reducir las emisiones, proteger los motores y mantener su sistema en funcionamiento durante más tiempo.

Si sigue los pasos adecuados y mantiene limpios los filtros, se asegurará de que su biogás sea seguro y esté listo para su uso.

Instalación y funcionamiento de sistemas de carbón activado para biogás

Pasos de la instalación

Debe seguir unos sencillos pasos para colocar filtros de carbón activado para biogás. Una buena configuración ayuda a que su sistema de purificación funcione bien. He aquí una guía sencilla para la mayoría de los proyectos de biogás:

Elija el carbón activado adecuado

Existen cuatro tipos principales para el uso del biogás:Carbón activo impregnado de yoduro de potasio

Carbón activo impregnado alcalino

Carbón impregnado de carbonato alcalinotérreo

Carbón activo catalítico

Cada tipo funciona mejor con determinadas sustancias nocivas. Por ejemplo, los grados de yoduro de potasio ayudan a eliminar el sulfuro de hidrógeno.

Dimensionar correctamente el filtro

Asegúrate de que el filtro es lo suficientemente grande. Si es demasiado pequeño, se llenará rápidamente. El filtro debe ajustarse a las necesidades de su sistema.Configurar la disposición del filtro

Utilice dos filtros en su sistema de biogás. Un filtro funciona mientras el otro espera. De este modo, puede cambiar de filtro sin detener el sistema. Su biogás sigue funcionando.Instale el filtro en la línea de gas

Coloque el filtro de carbón activado después del digestor. Colóquelo antes de que el gas vaya a los motores u otras unidades. Asegúrese de que el gas se mueve uniformemente a través del lecho de carbón.Comprobación de fugas y conexiones seguras

Revisa todas las tuberías y juntas. Apriételas para evitar fugas. Las fugas pueden hacer que tu sistema de depuración funcione peor.

Consejo: Siga siempre las normas de seguridad para el biogás. Utilice guantes y mascarillas cuando toque el carbón activado. Mantenga la zona abierta al aire fresco.

Funcionamiento y control

Después de instalar el filtro, debe hacer funcionar y vigilar su sistema. Un buen funcionamiento y comprobación ayudan a que su sistema de biogás funcione lo mejor posible.

Parámetros operativos clave

Es necesario controlar algunas cosas para que el sistema siga funcionando. La siguiente tabla muestra los aspectos más importantes del biogás:

Parámetro | Influencia en el rendimiento |

|---|---|

Caudal | Controla la capacidad del carbón para adsorber contaminantes |

Temperatura | Cambia la cantidad de carbono que puede eliminar el gas |

Presión | Ayuda al carbón a atrapar más impurezas |

Mantenga un caudal constante. Si el gas se mueve demasiado rápido, el carbón no puede atrapar todo lo malo. Vigile la temperatura. Un calor elevado puede hacer que el carbón funcione peor. Mantenga la misma presión para obtener los mejores resultados.

Técnicas de control

Es necesario saber cuándo el carbón activado está lleno. Una forma es medir la resistencia eléctrica en el lecho de carbón. Esta prueba muestra dónde está el frente de adsorción. Cuando la resistencia cambia, el carbón se está llenando. Puede adivinar cuándo cambiar el filtro.

Técnica de control | Descripción |

|---|---|

Medición de la resistencia eléctrica | Mide la resistencia en diferentes puntos en el lecho de carbono para seguir la saturación |

También puede utilizar sensores de gas para comprobar si hay sulfuro de hidrógeno después del filtro. Si ves más de estos, el carbón está lleno.

Nota: Anote siempre cuándo cambia los filtros y comprueba la calidad del gas. Esto le ayudará a planificar y detener los problemas en su sistema de biogás.

Consejos para un rendimiento y una seguridad óptimos

Cambie el carbón activado antes de que se llene. Esto mantiene su sistema funcionando bien.

Utilice dos filtros para que su sistema funcione todo el tiempo.

Mantén la zona limpia y seca para evitar accidentes.

Enseñe a su equipo formas seguras de actuar y qué hacer en caso de emergencia.

Si sigue estos pasos, su sistema de biogás funcionará bien y de forma segura. Protegerá sus máquinas y sacará el máximo partido a su biogás.

Mantenimiento en aplicaciones de biogás

Sustitución del filtro

Tienes que cambiar filtros de carbón activo para que su sistema de biogás funcione bien. Con el tiempo, estos filtros se llenan de sustancias nocivas y dejan de funcionar correctamente. Si espera demasiado, su sistema puede empezar a oler mal o incluso estropearse.

Una buena forma de saber cuándo debe cambiar el filtro es observar si se produce una penetración de sulfuro de hidrógeno. Esto significa que el filtro ya no puede eliminar los gases nocivos. Debe cambiar el filtro en cuanto lo detecte.

Condición | Acción |

|---|---|

Sustituir o reactivar el filtro |

Hay otros signos que indican que necesita un filtro nuevo:

Usted oler algo parecido a aguas residuales de su sistema de biogás.

El filtro se siente más pesado, lo que significa que ha absorbido agua y cosas malas.

Los malos olores que antes desaparecían empiezan a volver.

El filtro se ha utilizado durante todo su tiempo.

Firma | Descripción |

|---|---|

Si vuelven los malos olores, el filtro está lleno. | |

Aumento de peso | Un filtro pesado significa que ha absorbido agua y contaminantes. |

Caducidad | Cambie los filtros después del tiempo indicado por su proveedor. |

Consejo: Siga siempre el programa de cambio de filtros de su proveedor. Esto le ayudará a detener los problemas antes de que empiecen.

Cuando tire los filtros viejos, piense en la Tierra. El carbón activo usado puede causar problemas si lo depositas en un vertedero. Puede hacer gases de efecto invernadero como el metano y el dióxido de carbono. Tirarlo de forma incorrecta también puede contaminar el aire y perjudicar a las personas, sobre todo allí donde las normas de vertido no son estrictas.

Depositar el carbón activo usado en vertederos puede generar gases de efecto invernadero.

Las malas formas de tirarlo pueden contaminar el aire y perjudicar a las personas.

Los lugares con normas poco estrictas sobre vertederos tienen problemas mayores.

Solución de problemas

A veces su sistema de limpieza de biogás no funciona bien. Si huele algo mal, compruebe primero los filtros. Un olor fuerte suele significar que el filtro está lleno. Si el filtro se siente pesado o el gas no es tan bueno, cámbielo de inmediato.

Si sigue teniendo problemas después de cambiar el filtro, busque fugas en las tuberías o piezas sueltas. Asegúrese de que el gas se desplaza uniformemente por el lecho filtrante. Anote cuándo cambia los filtros y revisa el sistema. Esto le ayudará a encontrar los problemas y solucionarlos más rápidamente.

Nota: Realizar comprobaciones periódicas mantiene su sistema de biogás seguro y en buen estado de funcionamiento. Protege sus máquinas y obtiene los mejores resultados de su proceso de limpieza.

Puede mejorar su biogás utilizando carbón activado. Esto ayuda a eliminar las sustancias nocivas y mantiene tus máquinas seguras. La siguiente tabla muestra cómo ayuda el carbón activado a su sistema:

Beneficio | Descripción |

|---|---|

Prolonga la vida útil de los equipos | Detiene el óxido y el daño de las cosas malas en el gas. |

Mejora la calidad del biogás | Proporciona más energía para un mejor uso en los procesos de mejora del biogás. |

Reduce los costes de mantenimiento | Necesita menos limpieza y le ahorra dinero. |

Las revisiones periódicas y el cuidado del sistema contribuyen a su buen funcionamiento.. Para obtener los mejores resultados, prueba estos consejos:

Utilice prefiltros para atrapar la suciedad antes del filtro principal.

Controla la velocidad a la que se mueve el gas y el tiempo que está en contacto con el carbono.

Compruebe el gas a menudo y cambie los filtros cuando sea necesario.

Un biogás más limpio le ayuda a trabajar con seguridad y mantiene sus máquinas en funcionamiento durante más tiempo.