The uses of activated carbon pellets

Activated carbon pellets purify air, water, and gases, remove odors, and support industrial, agricultural, and home filtration needs efficiently.

Activated carbon pellets purify air, water, and gases, remove odors, and support industrial, agricultural, and home filtration needs efficiently.

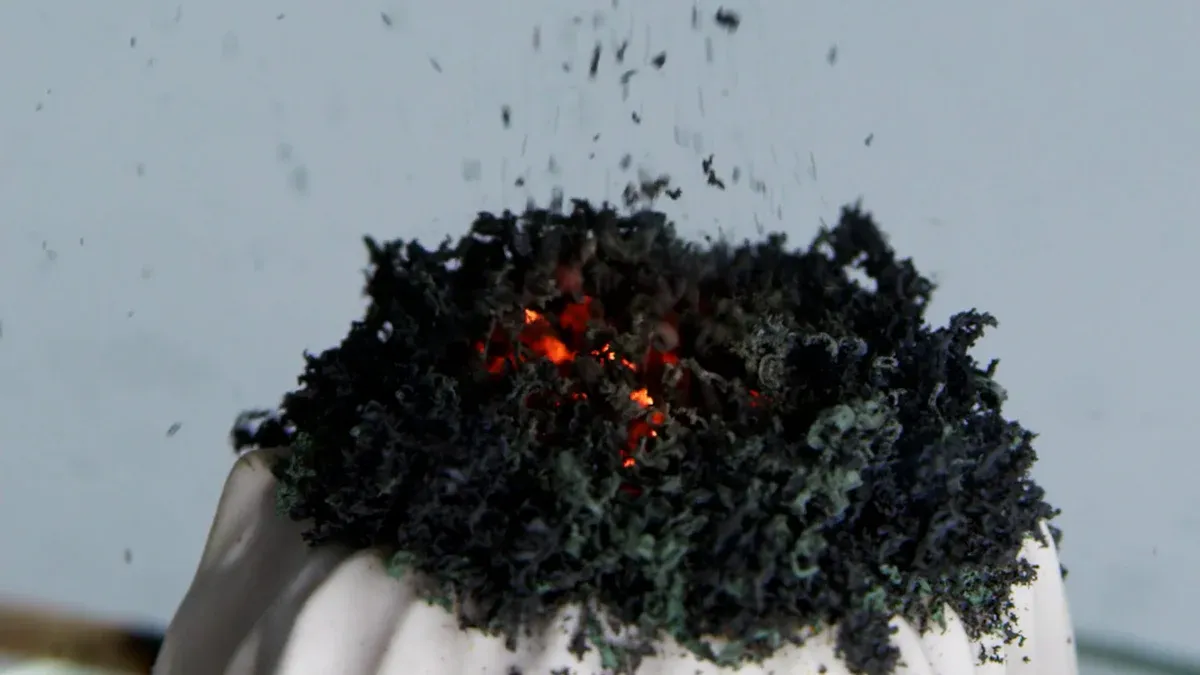

Fabricación de pastillas de carbón activado mediante la preparación de materias primas, la mezcla de aglutinantes, la extrusión, la carbonización y la activación para una adsorción óptima.

Amine impregnated activated carbon is a filter with amine groups that efficiently captures CO2, ammonia, and toxic gases for air purification.

KOH impregnated activated carbon removes acidic gases and contaminants from air and water, offering efficient purification for industrial and environmental use.

Copper impregnated activated carbon combines copper compounds with activated carbon to enhance contaminant removal, odor control, and antimicrobial action.

Manufacture granular activated carbon by selecting raw materials, carbonizing, activating, washing, drying, sizing, and packaging for optimal adsorption.

Impregnation activated carbon involves adding chemicals to enhance pollutant removal, improving selectivity and adsorption for air and water purification.

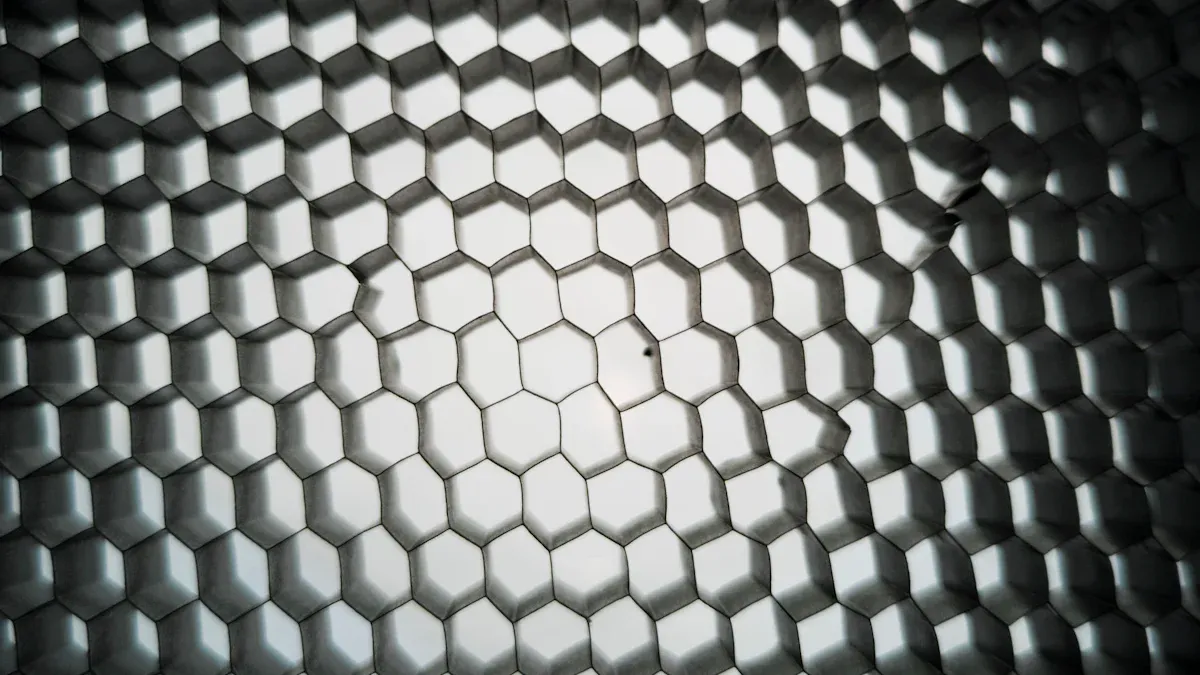

Granular activated carbon removes contaminants by adsorbing them in its porous structure, making it effective for water and air purification.

Granular activated carbon is a filtration material that removes chemicals and impurities from water and air, improving safety and taste in various applications.