Imagine you walk onto a construction site. You see puddles on the floor. The insulation looks wet. This is a big problem for your project. Moisture can hurt building materials. It can break equipment. It can slow down your work. Many experts in the Essiccante per l'industria delle costruzioni field say water causes most problems. Almost 90% of issues come from water. You see these problems everywhere:

85% of buildings get water damage at some time.

45% of buildings have leaks when checked.

Moisture causes more than $1 billion in damage each year.

You need tools to stop moisture. You want to keep your project safe. This guide will show you how to use desiccants step by step.

Punti di forza

Desiccants are important for keeping moisture low at building sites. They help keep materials and tools safe from water harm.

Pick the right desiccant for your project’s needs. Think about things like wetness, heat, and what you want to keep safe.

Desiccant dehumidifiers work well when it is cold. They help dry things faster and stop mold from growing.

Check and take care of your desiccants often. Change them only when they look worn out or dirty.

Using desiccants can help you save time and money. They make drying faster and lower the chance of water damage.

Essiccante per l'industria delle costruzioni

What Is a Desiccant

When you want to keep a building site dry, you might see the term construction industry desiccant. A desiccant is a material that takes moisture out of the air. You use it to keep building materials and equipment safe from water damage. In construction, it is important to keep things dry for safety and quality.

Desiccants work in two main ways. Some use adsorption, which means water sticks to their surface. Others use absorption, where water goes inside the material and changes form. Silica gel and activated alumina use adsorption. Calcium chloride uses absorption and turns water into liquid brine. These methods help control humidity and stop problems like mold or rust.

Suggerimento: There are many commercial desiccants you can pick from. Always check how they work at the molecular level. Some desiccants, like silica gel, have a big surface area. This lets them hold more water and work faster.

Here is a table that shows the most common types of commercial desiccants used in construction:

Tipo di essiccante | Descrizione | Usage in Construction |

|---|---|---|

A strong desiccant that absorbs lots of moisture. | Used often in construction. | |

Absorbs a lot of water and turns it into liquid brine. | Good for big moisture control jobs in construction. |

Specialty desiccant suppliers often suggest these products for large projects. When you buy desiccants, ask about their absorption or adsorption method. This helps you choose the right product for your needs.

Desiccants have special features that make them useful in the construction industry desiccant market. Here is a table that explains these features:

Proprietà | Descrizione |

|---|---|

Porosità | The amount of empty space in the desiccant, which affects how much moisture it can take in. |

Superficie | The total area that can hold moisture, which affects how well it works. |

Pore Size Distribution | The different sizes of pores, which change how fast moisture goes in and out. |

Chemical Composition | The materials that make up the desiccant, which affect how well it works and if it fits with other things. |

Resistenza meccanica | How well the desiccant can handle stress without breaking, which matters for construction. |

Moisture Capacity | The most water vapor the desiccant can hold, shown as a percent of its weight. |

Efficienza | How fast and well it lowers moisture in the air. |

Thermal Stability | How well it stays together at high temperatures, which is important for reuse. |

Compatibilità chimica | If the desiccant can be near other materials without causing problems. |

You want desiccants with strong mechanical strength and high moisture capacity. Specialty desiccant suppliers can help you find the best ones for your project.

Why Use Desiccants in Construction

Moisture causes many problems on a construction site. Regular heating systems do not remove enough water from the air. This makes concrete and other materials take longer to dry. You might see delays or mold if you do not use good moisture control.

Desiccant dehumidifiers help you control moisture better. They work well even when it is cold and do not freeze. You can use them to make very dry air, which dries wet materials faster. This helps you avoid delays and keeps your project moving.

Here are some reasons to use commercial desiccants in construction:

Desiccants take moisture out of the air even when humidity is low.

They work at low temperatures, so you can use them all year.

They make dry air that dries wet materials quickly.

They lower humidity and vapor pressure, which stops mold.

Desiccant dehumidifiers are more reliable than HVAC systems for moisture control.

Nota: Specialty desiccant suppliers often suggest desiccant dehumidifiers for big projects. These machines use commercial desiccants to keep the air dry and protect your materials.

You save time and money when you use construction industry desiccant solutions. Desiccant dehumidification lowers the relative humidity and dew point. This makes concrete and other surfaces dry faster. You can put in flooring sooner and lower the risk of mold. Other methods, like heating or cooling, do not remove enough water and can cause delays.

When you pick commercial desiccants from specialty desiccant suppliers, you get products made for tough construction jobs. These products help you keep quality high and your project on track.

Moisture Control Methods

Desiccant Dehumidification

It is hard to control moisture on a construction site. Desiccant dehumidifiers help lower humidity in many climates. These machines have a spinning desiccant wheel that takes water from the air. They work better than mechanical dehumidifiers when it is cold or the dew point is low. You will not see water made during use, so they work even in freezing weather.

Here is a table that shows how desiccant dehumidification and mechanical dehumidification are different:

Caratteristica | Desiccant Dehumidification | Mechanical Dehumidification |

|---|---|---|

Process | Uses a spinning desiccant wheel to take water from air. | Pulls wet air over a cold coil to make water. |

Temperature Efficiency | Works well in cold and low dew points. | Saves more energy when it is hot (about 30°C). |

Water Production | No water is made, so it works in freezing weather. | Water forms and is taken out of the air. |

Application | Good for special jobs like flood cleanups. | Used often for normal humidity control. |

Think about energy use before picking desiccant dehumidifiers. From May to September, they use about 60.5% of their yearly energy. The most energy is used in August, when it is most humid. Desiccant dehumidifiers dry wet materials fast and help stop mold. This keeps your project on time and your work high quality.

Suggerimento: Use more than one way to control moisture. Stop moisture from getting in, stop it from building up, and remove it. These steps work together to stop damage from moisture.

Material and Equipment Protection

You need to keep moisture-sensitive products and electronic parts safe from water damage. Desiccant dehumidifiers protect building materials in storage and in closed spaces like insulation panels. You also use desiccant to stop rust and corrosion on metal.

Here is a table that shows how desiccant helps protect against moisture:

Fonte | How Desiccant Protects |

|---|---|

Building Materials | Stops water damage in storage and closed spaces |

Metal Surfaces | Stops water drops, so no rust or corrosion |

Enclosed Spaces | Lowers humidity, keeping metal parts safe |

Desiccant breathers show real results. For example:

Deeter Foundry reached its goals for moisture and dirt, making things cleaner.

An oilseed company made breathers last 25% longer and saved on repairs.

An Oregon hay farm waited longer between fluid changes and saved $15,000 a year.

You can stop damage from moisture and keep your materials and equipment in good shape. Using desiccant lowers the chance of mold, rust, and other problems. You also save money on repairs and keep your project moving.

Types of Desiccants

You have many types of desiccants to pick for your project. Each one helps control moisture in its own way.

Gel di silice

Silica gel is a very common desiccant in construction. You might see it in small packets or in bigger amounts for large jobs. Silica gel has lots of tiny holes, so it can hold lots of water. It can take in up to 40% of its weight in water when it is humid. This makes it a good choice for keeping things dry.

Here is a table that shows why silica gel is special:

Proprietà | Descrizione |

|---|---|

High Specific Surface Area | The tiny holes let it take in more water. |

Moisture Adsorption | Can hold up to 40% of its weight in water. |

Chemical Stability | It does not react with most things and stays stable. |

Non-Toxicity | Safe to use near people and in many places. |

Versatilità | Comes in different forms, even ones that change color. |

Silica gel costs more than some other types. But you can use it again, so it saves money over time.

Argilla

Clay desiccant is natural and good for the environment. It is a cheap way to control moisture. Clay can take in water about 50% better than silica gel. It is safe, not poisonous, and easy to use. You do not need special tools to use clay desiccant.

Advantage/Limitations | Dettagli |

|---|---|

Cost-effective | Cheaper than silica gel, good for saving money. |

Natural and Eco-friendly | Made from clay, breaks down in nature. |

Elevata capacità di assorbimento | Takes in water well, even better than silica gel. |

Safe for Sensitive Applications | Not poisonous and does not cause rust. |

Easy to Use | Simple to use and handle. |

Moisture Release at Low Temps | Might let out water if it gets too cold. |

Clay desiccant works best when it is not too cold. If you need to control water in freezing places, try something else.

Cloruro di calcio

Calcium chloride is a strong desiccant for big jobs. Use it when you need to get rid of lots of water fast. Calcium chloride can take in up to 300% of its weight in water. After it takes in water, it turns into a gel, so you do not have to worry about leaks.

Calcium chloride works great when it is very humid.

It keeps things safe when you store or ship them.

It takes in water much faster than other desiccants.

⚠️ Safety Tip: Always wear gloves and safety glasses with calcium chloride. It can bother your skin, eyes, and lungs. If it touches your skin or eyes, wash with water and get help if you need it.

You can buy desiccants with calcium chloride for big projects. It costs less than silica gel and is good for large areas.

How to Use Desiccants

Selection Guide

You must pick the right desiccant for your project. First, think about what your job needs. Look at how big the area is. Check what materials you want to protect. Think about how wet or humid the place is. Desiccant dehumidifiers work best when it is very humid. They help with both types of heat in the air. These machines can save more energy than old methods. Sometimes, they use up to 7.7% less energy. You also spend less money because they cost less to run than cooling and heating.

When picking a desiccant, remember these things:

Pick a desiccant that matches the materials you want to keep safe.

Make sure it works for your site’s temperature and humidity.

Think about how long you need things to stay dry.

Check if it is safe for workers and the environment.

Choose one that fits your budget and project size.

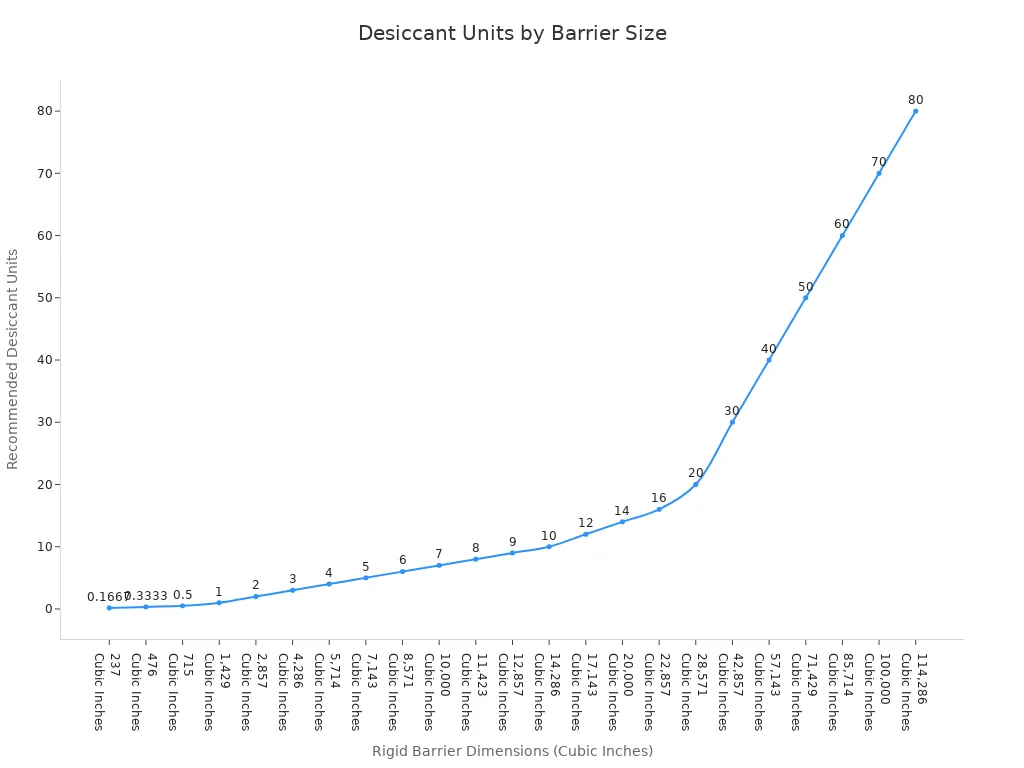

You also need to know how much desiccant to use. The table below shows how many units you need for different sizes. This helps you use the right amount.

Rigid Barrier Dimensions | Units Req. |

|---|---|

237 Cubic Inches | 1/6 |

476 Cubic Inches | 1/3 |

715 Cubic Inches | 1/2 |

1,429 Cubic Inches | 1 |

2,857 Cubic Inches | 2 |

4,286 Cubic Inches | 3 |

5,714 Cubic Inches | 4 |

7,143 Cubic Inches | 5 |

8,571 Cubic Inches | 6 |

10,000 Cubic Inches | 7 |

11,423 Cubic Inches | 8 |

12,857 Cubic Inches | 9 |

14,286 Cubic Inches | 10 |

17,143 Cubic Inches | 12 |

20,000 Cubic Inches | 14 |

22,857 Cubic Inches | 16 |

28,571 Cubic Inches | 20 |

42,857 Cubic Inches | 30 |

57,143 Cubic Inches | 40 |

71,429 Cubic Inches | 50 |

85,714 Cubic Inches | 60 |

100,000 Cubic Inches | 70 |

114,286 Cubic Inches | 80 |

Application Steps

You can use desiccant dehumidifiers and other products in many ways. They work for storage, moving things, and drying out spaces. Follow these steps to get good results:

Check the area or container before you start. Look for holes, check door seals, and make sure it is dry.

Pick the right desiccant for your materials and the place.

Figure out how much desiccant you need for the space and cargo.

Put the desiccant in the best spots. Spread it out so it can soak up water from everywhere.

Close up the area tightly. This keeps outside water from getting in and helps keep things dry.

Watch the conditions. Use tools to check if the desiccant is working.

💡 Suggerimento: Always follow the maker’s instructions. This helps you avoid mistakes and keeps your stuff safe from rust and damage.

You can use these steps for many jobs. They help protect building materials in storage, keep equipment safe when moving, or dry out wet places. Desiccant dehumidifiers work well for all these uses.

Monitoraggio e manutenzione

You should check your desiccant often to make sure it still works. Some desiccants can be used again and again for many years. Most last as long as the box or container, which can be 10 to 15 years or more. You do not need to replace them unless they get dirty or broken.

Punto chiave | Dettagli |

|---|---|

Regenerable Desiccant | You can use these many times without losing much power. |

Expected Lifespan | Most last for years, often as long as the cabinet (10-15 years or more). |

Replacement Indicators | You rarely need to replace them; most problems come from other parts, not the desiccant. |

Common Failures | Heaters, fans, or seals may break more often than the desiccant itself. |

Contamination or Damage | Change the desiccant if it gets dirty or broken. |

🛠️ Nota: If you see rust, mold, or high humidity, check your desiccant right away. Replace it if it looks used up or broken.

Common Mistakes and How to Avoid Them

People sometimes make mistakes when using desiccant dehumidifiers and other products. These mistakes can cause rust or bad moisture control. Here are some common mistakes and how to stop them:

Common Mistakes | Descrizione |

|---|---|

Inlet feed velocities | Do not use speeds lower than 3 fpm or higher than 5 fpm. This can cause trouble. |

High differential pressures | Running units at high pressure can make the desiccant wear out faster. |

Topping off desiccant beds | Do not put old desiccant at the bottom when adding new. |

Mixing different manufacturers | Do not mix products from different companies in the same unit. |

Inaccurate loading procedures | Always use the right steps for your job. |

Do not test desiccants where temperature and humidity change a lot. This can give you bad results.

Always test in a steady place to get good results.

⚠️ Safety Tip: Wear gloves and safety glasses when using desiccant products, especially calcium chloride. This keeps your skin and eyes safe.

Desiccant dehumidifiers and other products help you control water, stop rust, and protect your materials. Use them the right way to keep your project on track and keep your work high quality.

You can keep your construction project safe if you use desiccants correctly. Desiccants help things dry faster and stop problems before they start. They also keep mold from growing. Paints and adhesives work better and last longer when you control moisture.

You do not have to wait as long for things to dry, so you save money on repairs.

Using desiccants can cut the chance of mold by more than half.

There are fewer times you need to come back and fix things after finishing.

Benefici | Descrizione |

|---|---|

Efficient Curing | Materials dry on time, so your project stays on schedule. |

Structural Protection | Desiccants stop damage and help you spend less on repairs. |

Energy Savings | You use less energy because moisture is controlled better. |

When you control moisture, buildings become stronger and last longer. Try these steps to get better results on every job.