You use medical grade desiccant to protect medicines and devices from water in the air. Even a little moisture can cause big problems. Products might stick together or tests might not work right. More people want Essiccante per uso medico because the healthcare field faces these dangers.

Risk Type | Descrizione |

|---|---|

Manufacturing | Too much water can make products stick. This can hurt how they look and slow down making them. |

Stoccaggio | Wet air can cause things to break down or grow germs. It can also ruin packaging. |

Imballaggio | Water can make powders stick when filling. This can hurt the quality of the product. |

Nutraceuticals | Wet places can make products turn out different each time. It can also slow down how fast they are made. |

Diagnostic Kits | Some parts soak up water and can change if wet. This can make test results wrong. |

Punti di forza

Medical grade desiccants keep medicines and devices dry. They stop moisture from getting in. This helps prevent spoilage. It also keeps the product good to use.

Pick the right desiccant for your product. Silica gel works for many things. Molecular sieves are best when you need things very dry.

Make sure your desiccant follows safety rules. Look for FDA regulations and ISO certifications. This keeps products and people safe.

Use the right amount of desiccant in your package. Too much or too little can hurt the product or waste materials. Test desiccants in real storage places.

Follow good steps when using desiccants. Seal packages fast after adding desiccants. This helps keep everything dry.

What Is a Medical Grade Desiccant

A medical grade desiccant keeps medicines and devices safe from water. These desiccants are in many healthcare products. They stop water from causing damage. Using the right desiccant helps prevent spoilage and clumping. It also stops germs from growing.

Key Features

You should check for certain features when picking a medical grade desiccant. These features help your products stay safe and work well:

Regulatory compliance means the desiccant follows FDA safety rules.

Quality control shows the desiccant is made in a good facility.

Medical grade desiccants use different materials. Each material works best for certain needs. Here is a table to show the most common types:

Material | Properties and Applications |

|---|---|

Gel di silice | Highly absorbent, non-toxic, inert; ideal for sensitive product packaging. |

Essiccanti argillosi | Environmentally friendly, effective moisture absorption, but less capacity than silica gel. |

Setacci molecolari | Very low humidity control, used in industrial applications requiring precise moisture levels. |

Carbone attivo | Absorbs odors and chemicals, also aids in moisture control for various industrial uses. |

Silica Gel + Activated Carbon | Combines moisture absorption with odor control, useful in packaging and purification. |

Silica Gel + Molecular Sieve | Enhanced moisture control for sensitive products needing very dry environments during storage or transport. |

Tip: Pick the right desiccant for your product. Silica gel is good for most medicines. Molecular sieves are better for things that need very dry air.

Safety Standards

Your medical grade desiccant must meet strict safety rules. These rules keep products and people safe. Look for these important things:

ISO 15378:2017 means the facility meets global packaging rules.

A Type III Drug Master File with the USFDA helps with use in the US.

Following 21 CFR, RoHS, and HACCP adds more safety.

Groups like the FDA and EMA check many things before they allow a medical grade desiccant. Here is a table that shows what they look for:

Key Considerations | Descrizione |

|---|---|

Material Safety | Desiccants must be non-toxic and non-reactive. |

Packaging Integrity | Desiccant packaging should prevent leakage and contamination. |

Compliance Documentation | Proper documentation is required to demonstrate regulatory compliance. |

Choosing a desiccant that meets these rules helps keep patients safe. It also protects your products from harm and loss.

How They Work

Moisture Absorption

Medical grade desiccants help keep products safe from water in the air. They pull water out from inside sealed packages. Each kind of desiccant has its own way to take in water. Here is a table that shows how some types work:

Tipo di essiccante | Mechanism of Absorption |

|---|---|

Chemical Desiccants | Bind water through chemical reactions, often with metal oxides, and generate heat. |

Trap water on their surface using tiny pores, a process called surface adsorption and capillary condensation. | |

Setacci molecolari | Selectively trap water molecules based on size and polarity, working well even at low humidity. |

Silica gel and molecular sieves are used in medicine packaging a lot. These materials react to how much water is in the air. If the air is wet, they soak up more water. If the air is dry, they keep the water they already have. This keeps the inside of the package dry and steady.

Suggerimento: Desiccant canisters are small but strong. You can use them to keep bottles and packs dry.

Product Protection

Medical grade desiccants do more than just take in water. They help protect medicines and devices in many ways. Keeping water away stops lots of problems:

Tablets and powders do not stick together.

The main parts of medicines stay safe.

Products do not break down or change.

Germs are less likely to grow inside the package.

Desiccants also help products last longer. They control water and oxygen in the package. This keeps medicines and devices safe from rust and damage. For example, USP/EP-grade silica gel follows strict rules, so it is safe to use with drugs. By keeping things dry, desiccants help products stay safe, work well, and last longer.

Types of Medical Grade Desiccant

Ci sono different types of medical grade desiccant. Each type is good for certain uses. Here are some common kinds you might see:

Gel di silice

Gel di silice is a very popular choice. You can find it in small packets in medicine bottles. It soaks up water and keeps things dry. Silica gel is safe to use with food and medicine. It is not poisonous. You can use it again by heating it to dry it out.

Vantaggi | Disadvantages |

|---|---|

Moisture absorption efficiency may vary compared to other desiccants | |

Non corrosivo | |

Non tossico | |

Rigenerabile | |

Versatile |

Some packs use Tyvek or Wisesorb and are filled with silica gel. These packs do not have cobalt chloride or ink. This helps keep your products safe.

Setaccio molecolare

Molecular sieves are good when you need very dry air. They can make the air inside a package almost free of water. They work fast and hold water tightly, even when it is cold. You often see them in packages for sensitive drugs.

Molecular sieves hold water better than silica gel or clay.

They let you dry things without losing other important parts.

Tipo di essiccante | Ideal Applications | |

|---|---|---|

Setacci molecolari | Stringent moisture control | |

Gel di silice | Moderato | Wide range of uses |

Moderato | General moisture control | |

Cloruro di calcio | Alto | Bulk applications |

You might find molecular sieves in special paper or canisters for medicine bottles.

Argilla Montmorillonite

Montmorillonite clay is a natural and green choice. It soaks up water well and is safe for food and medicine. This clay is not harmful to the earth. It is not poisonous. Companies use it to help the planet and cut down on waste.

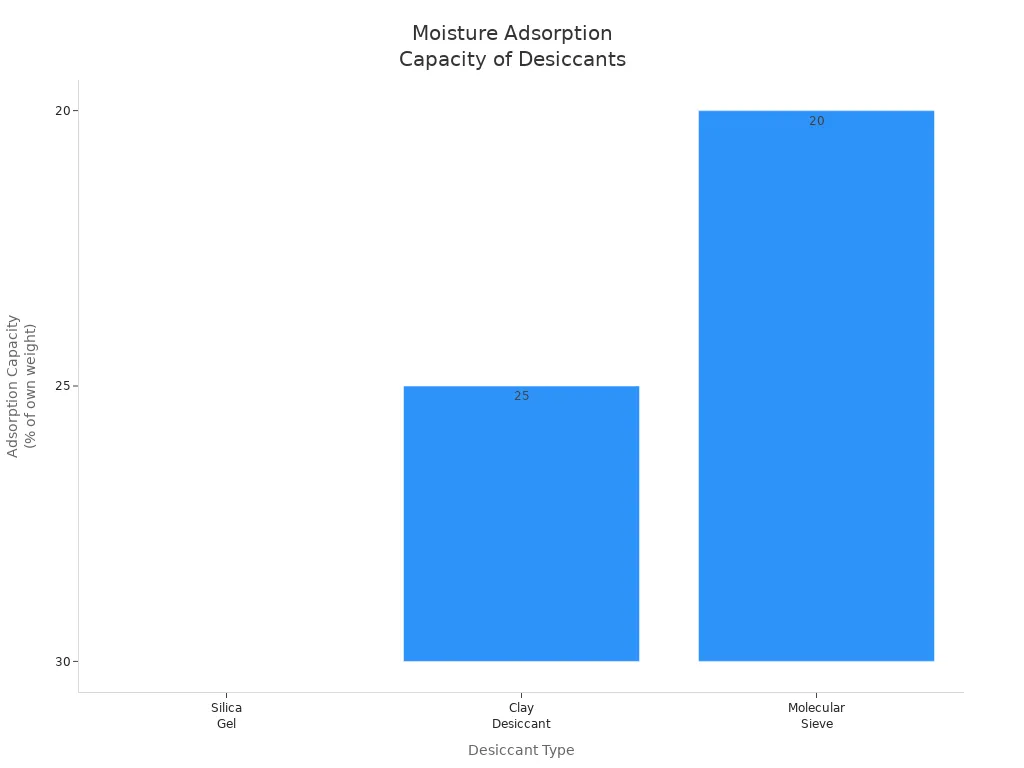

Tipo di essiccante | RH Range of Peak Efficiency | Adsorption Capacity (at 50% RH, 25°C) | Thermal Stability | Dust Generation |

|---|---|---|---|---|

Gel di silice | 40-70 % RH | ≈ 30 % of its own weight | Up to 149 °C (300 °F) | Very low |

Clay Desiccant | 30-60 % RH | ≈ 25 % of its own weight | Drops sharply above 50 °C (122 °F) | Moderate if crushed |

Setaccio molecolare | 0-30 % RH | ≈ 20 % of its own weight (but very fast kinetics) | Up to 260 °C (500 °F) | Negligible |

Tip: Pick packs that do not have cobalt chloride or ink. This helps keep your products and people safe.

You can get montmorillonite clay in Tyvek bags and other green packs.

Choosing Desiccants

Picking the essiccante giusto is very important. You must think about what you want to keep safe. You also need to know how much space you have. Think about how long you need things to stay dry. The right choice keeps medicines and devices safe.

Packaging and Dosage

È necessario match the desiccant to your package and product. Here are some things to think about:

Product Sensitivity: Ask if your product needs very dry air. Some medicines and devices need extra dryness.

Packaging Type: Look at your package. Bottles, blister packs, and pouches need different desiccant shapes. Canisters and packets fit in bottles. Flat packs work better in pouches.

Shelf Life: Think about how long your product will sit on the shelf. The desiccant must work the whole time.

Storage Conditions: Check where you will store and ship your product. Some desiccants work better in hot or wet places.

Dosage Calculation: Use the right amount of desiccant. Too little will not protect your product. Too much wastes money. Think about the package size, how much water your product has, and how much air gets in.

Space and Placement: Make sure there is enough room for the desiccant. Put it where it works best.

Tip: Seal your package right after adding the desiccant. This keeps outside water from getting in.

Desiccants keep the inside of your package dry. They stop water vapor from causing clumps, mold, or changes in how medicine dissolves. Do not reuse a desiccant unless you know it is still safe.

Compliance and Testing

You must follow strict rules when using a medical grade desiccant. Different places have their own rules. Here is a table that shows the main agencies and rules:

Region | Regulatory Agency | Standard |

|---|---|---|

US | FDA | US FDA standards |

UE | EMA | EU GMP standards |

Global | ISO | ISO certifications |

You must make sure your desiccant meets these rules. This means checking that it is safe and pure. It should be made in a good place. You should also test your desiccant in real situations. Testing helps you know if it still works. If you use the wrong kind or amount, your product might not stay safe. Problems can include product breakdown, weak medicine, or recalls.

Note: Always use desiccants approved for direct contact with medicines or devices. This keeps your product and people safe.

Application Examples

You can find medical grade desiccant in many healthcare products. Here are some real examples:

Pill bottles have silica gel packets to keep tablets dry.

Blister packs use small strips to stop water from getting in.

Diagnostic kits have desiccant packs to protect test strips.

Medical devices, like glucose meters, use desiccants to stop rust and keep electronics working.

Pharmaceutical companies have fewer product returns after using desiccants. Some see up to a 15% drop in returns from water problems. This shows how important desiccants are for keeping products safe.

You should always follow best practices when using desiccants:

Pick the right type for your product and storage place.

Use the right amount for your package and expected water.

Test the desiccant in your real storage and shipping place.

Seal products fast after adding the desiccant.

Never reuse desiccants unless they are made safe again.

Desiccants help protect medicines and devices. They keep products safe, stable, and ready for patients.

You help keep medicines and devices safe by picking the right medical grade desiccant. These desiccants help drugs last longer and stay strong. This helps make sure the products are good to use. If you follow safety rules and check for changes, you can stop recalls and problems.

Controlling moisture all the time keeps products safe and helps patients. You also help the planet by choosing green packaging and new ideas. Watching these things closely makes things better for patients and healthcare groups.