The activated carbon manufacturing process involves several crucial steps, including carbonization, activation, washing, drying, sizing, and packaging. The specific approach to making activated carbon varies depending on the raw material used. Common raw materials include coconut shell, coal, wood, and nut shells. For example, Coconut Shell Activated Carbon and Nut Shell Activated Carbon are produced by heating the material at high temperatures with limited oxygen. In contrast, Coal-Based Activated Carbon and Wood Based Activated Carbon require specialized activation techniques to develop distinct pore structures. Controlling heat and activation agents precisely is essential in the activated carbon manufacturing process. Manufacturers select equipment and process parameters based on the type of activated carbon they aim to produce and its intended application.

Raw Material | Carbonization Process | Activation Method | Resulting Pore Structure | Typical Applications |

|---|---|---|---|---|

Coal-Based Activated Carbon | Heated at high temperature under oxygen-deficient conditions | Physical activation (steam, CO2) | Mainly micropores to large pores | Water treatment, industrial gas purification |

Coconut Shell Activated Carbon | Heated at high temperature in oxygen-deficient environment | Physical activation (steam) | Mainly microporous | Water and air purification |

Wood Based Activated Carbon | Heated in oxygen-deficient environment, chemically activated | Chemical activation (acid impregnation) | Rich mesoporous and macroporous structure | Decolorization, gas adsorption |

Key Takeaways

Activated carbon is made by heating things like coconut shells, coal, or wood. The steps are carbonization, activation, washing, drying, sizing, and packaging.

Physical activation uses steam or carbon dioxide at high heat. This makes small pores and is good for the environment. Chemical activation uses acids at lower heat. It makes even pores but needs a lot of washing.

Picking the right raw material changes the quality, cost, and use of activated carbon. Coconut shells make hard, long-lasting carbon. Coal gives different pore sizes. Wood is renewable and has good medium-sized pores.

Special machines like rotary kilns, washing units, dryers, and sizing machines are used. They help heat, clean, dry, and size the carbon for good quality.

Quality control tests check iodine value, pH, ash content, and strength. These tests make sure the activated carbon works well and is safe. It can be used for water, air, food, and industry.

Activated carbon comes in granular, powdered, and bead forms. Each type is best for jobs like cleaning water, removing pollution fast, or cleaning air.

Makers should control the process, keep machines working, and follow safety and environmental rules. This helps make good and eco-friendly activated carbon.

Using the right type and size of activated carbon for each job is important. It helps clean better and saves money and resources.

Activated Carbon Manufacturing Process

Steps Overview

The activated carbon manufacturing process changes raw materials into porous carbon. There are several main steps in this process. Each step is important for the quality of the final product.

Carbonization

Manufacturers start by picking and preparing raw materials like coconut shells, coal, or wood. They clean and dry these materials to get rid of dirt and water. During carbonization, the material is heated without much oxygen at 600°C to 900°C. This step removes gases and makes a basic pore structure. The carbonized material, called char, is used for the next steps.

Activation

Activation is the most important part of the activated carbon manufacturing process. In this step, the char is treated to make more pores. Manufacturers use either physical or chemical activation. Physical activation uses hot steam or carbon dioxide at 800°C to 1100°C. The steam reacts with the carbon and makes many small pores. Chemical activation uses things like phosphoric acid or zinc chloride at 400°C to 700°C. These chemicals help make more pores in the carbon. The method chosen depends on the raw material and what kind of activated carbon is needed.

Washing & Drying

After activation, the activated carbon is washed and dried. Washing gets rid of leftover chemicals, ash, or other things. Water or mild acids are often used for washing. Good washing is needed for activated carbon used in water or food. Drying removes water and gets the product ready for the next steps.

Sizing & Packaging

The last steps in the activated carbon manufacturing process are sizing and packaging. Machines grind and sift the activated carbon to get the right size. Having the right size is important for things like water cleaning or air filters. After sizing, the activated carbon is packed in containers that keep out moisture.

Tip: Keeping the size the same and packing carefully helps the activated carbon work well during shipping and storage.

Physical vs. Chemical Activation

Manufacturers use two main ways to activate carbon: physical activation and chemical activation. Each way has its own good and bad points.

Physical activation uses high heat and gases like steam or carbon dioxide. This happens at 800°C to 1100°C. The gas reacts with the carbon and makes small pores. This way does not need chemical washing, so it is better for the environment. But it can make less product and the pores may not be even.

Chemical activation uses things like phosphoric acid or zinc chloride at lower heat, usually 400°C to 700°C. The chemicals go into the raw material and help make even pores. Chemical activation usually makes activated carbon with more surface area and takes less time. But it needs a lot of washing to remove chemicals, which can cost more and hurt the environment.

Aspect | Physical Activation | Chemical Activation |

|---|---|---|

Activation Agents | Steam, CO2 | Phosphoric acid, ZnCl2 |

Temperature Range | 800–1100°C | 400–700°C |

Porosity Development | Smaller, less uniform pores | Highly porous, uniform structure |

Environmental Impact | No chemical residues | Requires washing, potential pollution |

Cost | Lower | Higher (due to chemicals and washing) |

Activation Yield | Lower | Higher |

Typical Use | Waste-derived carbons, water treatment | High-porosity carbons, specialty applications |

The way manufacturers choose depends on the raw material, pore size wanted, cost, and the environment.

Equipment Used

The activated carbon manufacturing process needs special equipment for good results. The rotary kiln is the main machine for carbonization and activation. This round furnace turns slowly and heats the material evenly. For chemical activation, manufacturers use tanks to mix raw materials with chemicals before heating.

Washing units clean out leftover chemicals and ash after activation. Drying ovens or air dryers take out water. Grinding and sifting machines make sure the activated carbon is the right size. At the end, automatic packaging systems keep the finished product safe from water and dirt.

Note: Taking care of the equipment helps keep the activated carbon manufacturing process safe and the product high quality.

Raw Materials for Activated Carbon

Many different raw materials are used to make activated carbon. The material chosen changes how the final product works and how much it costs. Manufacturers pick what is easy to get, not too expensive, and fits what they want the activated carbon to do. The most used materials are coconut shells, nut shells, coal, and wood. Each one has its own special benefits in making activated carbon.

Coconut Shell & Nut Shell

Coconut shell activated carbon and nut shell activated carbon are very popular in Asia Pacific. These shells are good for making activated carbon for many reasons:

They have lots of cellulose and hemicellulose, which help make strong pores.

They do not have much ash or water, so the quality is better.

They have a lot of fixed carbon, which helps in making more activated carbon.

Silicon in the shells helps them adsorb things better.

Nut shells are tough, strong, and last a long time.

Manufacturers use coconut shell based activated carbon to clean water and air. Nut shell activated carbon is good for taking out bad gases, removing color, and getting rid of smells in factories. Coconut shell activated carbon has small macropores, so it can adsorb a lot.

Note: If there are not enough coconut shells or nut shells, it can be hard to make enough activated carbon. This can also make prices go up, especially where many people want it.

Coal

Coal-based activated carbon is the most used type in the world. Manufacturers like coal because it is easy to find, not too costly, and works well for cleaning water. The main types used are bituminous and sub-bituminous coals. These coals react well and have lots of pores, which is important for good activated carbon.

Some things that change how coal-based activated carbon works are:

The type and size of the coal

What chemicals are in the coal

How it is activated (with chemicals or heat)

The temperature used for activation

Even low-rank coals with lots of ash can be used if the ash is removed. Coal that is activated with chemicals often has more surface area and can adsorb more than coal activated with heat. This makes coal-based activated carbon great for cleaning lots of water and treating gases in factories.

Type of Coal | Suitability for Activated Carbon | Typical Use Cases |

|---|---|---|

Bituminous | High | Water treatment, air purification |

Sub-bituminous | High | Industrial applications |

Lignite | Moderate | Specialty carbons |

Wood

Wood is a good, renewable material for making activated carbon. It keeps growing in nature and is made by many industries, so there is always more. Wood has natural pores, which helps make activated carbon that can adsorb a lot.

Manufacturers use leftover wood from factories to save money and help the environment. They use steam or chemicals to make even more pores in the wood-based activated carbon. This makes the product have a big surface area and work well.

Wood biomass has good pores for structure.

Using steam at high heat makes new pores and opens blocked ones.

Wood-based activated carbon is better for the environment than coal-based, and it helps manage waste.

Wood activated carbon is used to remove color, adsorb gases, and in special jobs where lots of mesopores are needed.

Coconut Shell Activated Carbon Manufacturing Process

Preparation

The coconut shell activated carbon manufacturing process starts with getting the raw materials ready. Workers at a coconut shell activated carbon plant pick only dry coconut shells. They want the best quality. They clean the shells and take off any dirt or trash. Then, they break the shells into small pieces. These pieces are about 2 to 5 millimeters big. Making the pieces small helps heat spread evenly in the next step. Good preparation helps the coconut shell activated carbon plant make the same product every time. It also helps the process work better.

Tip: Keeping the pieces the same size helps the carbonization process work well. It also helps make better pores in the final activated carbon.

Carbonization

After getting ready, the coconut shell activated carbon production goes to carbonization. In this step, the small coconut shell pieces are heated with very little oxygen. This takes out gases and leaves a material called char. The heat and other conditions in carbonization are very important for coconut shell activated carbon quality.

Scientists found that the best carbonization depends on the coconut type. For tall trees, the best phosphoric acid is 0.67 M with a pH of 2.07. The temperature should be between 450°C and 575°C. For dwarf trees, the best acid is 1 M with a pH of 1.98. The best temperature is about 575°C. If the temperature is too high, there is less product. But 575°C makes coconut shell based activated carbon that adsorbs very well. These facts help manufacturers choose the best settings for good coconut shell activated carbon.

Activation

The activation step changes the char into coconut shell activated carbon with lots of pores. Manufacturers use two main ways: steam activation and chemical activation. In steam activation, the char is heated to 800°C to 1100°C in a rotary kiln. Steam goes through the char and takes out gases. It also makes the pores bigger. This way makes coconut shell based activated carbon with a big surface area. It is great for cleaning water and air.

Chemical activation is another way. Here, the char soaks in chemicals like phosphoric acid. Then it is heated at lower temperatures, about 400°C to 700°C. This also makes more pores but uses less energy. Both ways make more surface area and pore space. These things are important for how well coconut shell activated carbon adsorbs. The choice between steam and chemical activation depends on what pore size is needed and how the product will be used.

Note: Steam activation works very well for coconut shell based activated carbon used in water treatment. It makes pores big enough to catch bad things in water.

Washing & Drying

After activation, workers wash the coconut shell activated carbon. They use clean water to remove chemicals and ash. This step makes sure the product is safe and pure. Sometimes, mild acids help get rid of tough residues. Washing also helps control the pH level. This is important for water purification.

Next, the material is dried. Workers use ovens or air dryers to take out extra water. Low moisture is needed for good quality and storage. Most grades must have less than 5% moisture. Powdered forms can have up to 15%. If the activated carbon is too wet, it does not work well. It can also spoil while being stored.

Strict checks happen during this stage. Each batch is tested for moisture, pH, ash, and adsorption. These tests make sure the product meets standards. They also help the product work well in real life.

Tip: Drying and storing the product right keeps coconut shell activated carbon safe from water and air. This helps it stay strong and useful.

Sizing & Packaging

After drying, workers crush and sift the activated carbon. They do this to get the right particle size. Mesh size is important for many uses. For example, 90% of the product should be between mesh sizes 4 and 8. Only 5% can be outside this range. Careful sizing helps the activated carbon work well in filters.

The plant checks important properties before packing. These are:

Hardness of at least 98%

Iodine number of 1100 mg/g or more

Ash content no higher than 5%

Moisture content about 5%

Density between 29 and 32 lbs/ft³

Workers use strong vinyl bags for packaging. Bags are usually 55 lb or 1,100 lb. Some customers want bulk packaging like big sacks or boxes. Workers seal the bags tightly to keep out water and dirt. They label each bag with batch number and product grade.

Property | Standard Value |

|---|---|

Mesh Size Distribution | 90% between 4–8 mesh |

Hardness | ≥ 98% |

Iodine Number | ≥ 1100 mg/g |

Ash Content | ≤ 5% |

Moisture Content | ≤ 5% |

Density | 29–32 lbs/ft³ |

Packaging Options | 55 lb, 1,100 lb vinyl bags |

⚠️ Safety Note: Wet activated carbon can lower oxygen in closed spaces. Workers must follow safety rules when handling and storing it.

Sizing and packaging help coconut shell activated carbon stay high quality. These steps make sure it meets standards and works well for users.

Coal Activated Carbon Manufacturing

Coal Types

Coal-based activated carbon is made from different kinds of coal. Manufacturers pick bituminous, sub-bituminous, or lignite coal for making it. Bituminous coal has lots of carbon and makes strong pores. This makes it good for cleaning water and for factories. Sub-bituminous coal costs less and still works well. Lignite coal has less carbon but can still work if processed right. The type of coal changes the pore shape, how much it can adsorb, and the final quality.

Carbonization

Carbonization is an important step in making coal-based activated carbon. In this step, workers heat coal without oxygen. This takes out gases and makes pores. How fast they heat, the temperature, the air, and the time all matter. Heating faster lets out more gas and takes less time. High heat, between 900°C and 1100°C, helps release gases like hydrogen and methane. The air must not have oxygen, so they use nitrogen to stop burning and control tar. Longer times help break down coal better and make more pores.

The table below shows the main things for coal carbonization:

Parameter | Description / Effect |

|---|---|

Heating rate | Changes how coal breaks down; faster rates make more gas and semi-coke. |

Temperature | High heat is needed; it changes gas release and syngas quality. |

Atmosphere | No oxygen (like N2) stops burning; it also changes tar. |

Time | More time helps break down coal and let out gases. |

Impregnation ratio (activation stage) | Changes the final activated carbon. |

Activation temperature and time (activation stage) | Change the pores and surface area. |

These things help control how gases leave, how cracks form, and how pores grow on the coal. If done right, the coal-based activated carbon will have strong adsorption.

Activation

Activation turns the carbonized coal into coal-based activated carbon with lots of pores. There are two main ways to do this:

Soak the coal in phosphoric acid, then heat it in nitrogen at 400–600°C for 1–3 hours.

Heat good coal at 900–1100°C with no oxygen.

Both ways take out gases and make more pores. Chemical activation makes even, tiny pores and helps it adsorb more. Physical activation at high heat also makes tiny pores and keeps the product stable in acids and bases. These steps change the coal’s structure, remove some groups, and make more pores. Coal-based activated carbon made this way can clean up to 90% of pollutants from water, including both organic and inorganic stuff.

Tip: Picking the best activation method helps make coal activated carbon that works well for many uses.

Washing & Drying

Washing and drying are very important for making pure coal activated carbon. Manufacturers use several steps to clean the product. First, they mix softened water with acid. This mixture goes into the bottom of the washing pool. It moves up through the carbon. Workers watch the acid strength, how long it sits, and the temperature. These things help get rid of bad stuff.

After the first wash, they might do it again. They repeat until most ash and metals are gone. When acid washing is done, the carbon gets an alkaline wash. This step removes any acid left over. Then, they rinse the carbon many times with clean water. This makes sure nothing is left on the carbon.

Manufacturers clean and reuse the washing water in a special system. This helps the environment and saves water. After washing, the carbon goes to drying. Workers use a drying furnace with different heat zones. This helps dry the inside and outside of each carbon piece. The finished coal activated carbon has little ash and is very pure.

Tip: Careful washing and drying make coal activated carbon cleaner. This helps it work better for cleaning water and air.

Sizing & Packaging

After drying, workers size and pack the coal activated carbon. They crush and sift the carbon to get the right size. Keeping the size the same helps meet what customers want.

Manufacturers put coal activated carbon in standard bags. Common bag sizes are 25 kg, 500 kg, 550 kg, and 600 kg. The 25 kg bags use strong plastic with a liner inside. This keeps the carbon dry and clean. Workers put these bags on pallets. Usually, they group 20 or 10 bags on each 500 kg pallet. They wrap the pallets to make big, safe bags.

For easy moving, two big bags go on a strong pallet. Forklifts can lift and move these safely. Special packing rooms help keep the product good and ship it on time. Many factories are close to big ports like Mumbai. This helps send coal activated carbon to other countries quickly.

🛡️ Note: Good sizing and packing keep coal activated carbon safe from water and damage when shipping and storing.

Wood Activated Carbon Manufacturing

Wood Selection

Manufacturers pick wood with lots of carbon for making activated carbon. Both hardwoods and softwoods can be used. The best wood has between 50% and 90% carbon. Wood has three main parts: hemicellulose, cellulose, and lignin. Lignin is about 15% to 35% of wood. It has a lot of carbon and makes the activated carbon strong. Cellulose and hemicellulose help build the structure for adsorption.

Wood biomass has many good points. It grows fast and can be cut often. This makes it cheap and easy to get. The mix of hemicellulose, cellulose, and lignin helps make activated carbon with a big surface area. It also creates many mesopores. These things make wood-based activated carbon great for cleaning water.

Tip: Picking wood with more lignin gives more carbon and makes the final product stronger.

Carbonization

During carbonization, workers heat wood chips with little oxygen. This step takes out gases and leaves char. Char is the base for activated carbon. The chemicals in the wood change how it breaks down and forms pores.

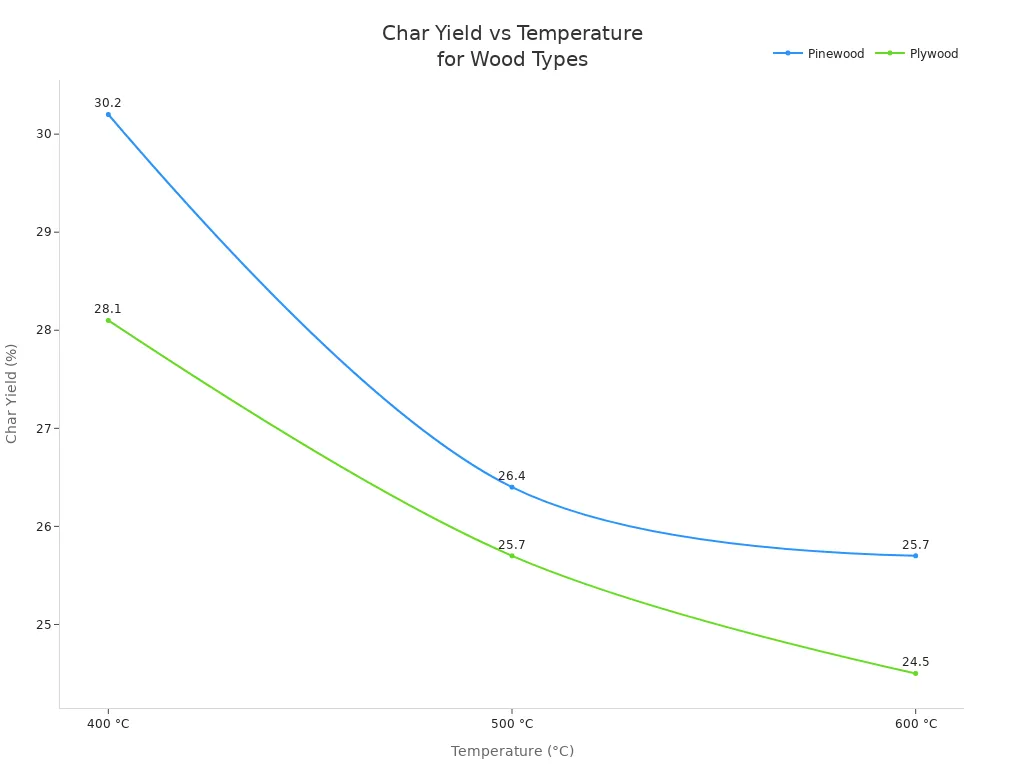

Scientists found that pinewood and plywood finish carbonizing at 500°C in 30 minutes. Heating at 10°C per minute and using nitrogen at 0.5 liters per minute works best. Raising the heat or time does not give more char. The table below shows the best carbonization settings for wood chips:

Wood Type | Temperature (°C) | Residence Time (min) | Heating Rate (°C/min) | N2 Flow Rate (L/min) | Char Yield (%) | Key Observation |

|---|---|---|---|---|---|---|

Pinewood | 500 | 30 | 10 | 0.5 | ~26.4 | Fully carbonized; char yield stable beyond 30 min and 500 °C |

Pinewood | 400 | 60 | 10 | 0.5 | 30.2 | Incomplete carbonization at lower temperature |

Pinewood | 600 | 60 | 10 | 0.5 | 25.7 | No significant improvement over 500 °C |

Plywood | 500 | 30 | 10 | 0.5 | 25.7 | Fully carbonized; extending time beyond 30 min has no effect |

Plywood | 400 | 60 | 10 | 0.5 | 28.1 | Incomplete carbonization at lower temperature |

Plywood | 600 | 60 | 10 | 0.5 | 24.5 | No significant improvement over 500 °C |

Activation

Manufacturers use two main ways to activate wood-based activated carbon. These are steam activation and chemical activation. Steam activation makes many small pores. Water molecules are tiny and move fast. They can reach the smallest pores easily. This method also adds special groups with oxygen. These groups help with adsorption.

Steam activation makes lots of micropores for adsorption.

Water molecules move fast and reach more pores.

The process adds groups that help with adsorption.

Chemical activation uses potassium hydroxide (KOH) at high heat, like 850°C. This makes activated carbon with a very large surface area, up to 3000 m²/g.

Other chemicals like phosphoric acid and zinc chloride can also activate wood. These are good for making mesoporous carbons.

Chemical activation with KOH at 850°C makes activated carbon that works well for water cleaning and supercapacitors. Steam activation is still the top choice for making microporous wood-based activated carbon.

Note: The activation method picked depends on what pore size is needed and how the product will be used.

Washing & Drying

Manufacturers wash and dry wood-based activated carbon with care. This process gets rid of things that should not be there. It also gets the product ready for many jobs. Every step makes the carbon cleaner and better.

Acid Washing: Workers treat the activated carbon with steam and hydrochloric acid. This step takes out ash and other unwanted stuff. Removing these things makes the carbon pure and helps it adsorb more. Good activated carbon is needed for medicine, food, and water cleaning. Acid washing helps the product meet tough rules for these uses.

Water Washing: After acid washing, workers wash the carbon with water. This step balances the pH and takes away leftover acid or dirt. Clean water runs through the carbon until the pH is safe and neutral. This helps the activated carbon work well for filtering and safety.

Drying: The last step is drying. Workers use ovens or air dryers to take out water from the activated carbon. The goal is to keep moisture below 10%. Less water helps the product stay good when stored or moved. Drying also makes packing easier and keeps the activated carbon fresh longer.

Tip: Washing and drying the right way help wood-based activated carbon work better. Clean and dry carbon does a great job in filters and other systems.

Sizing & Packaging

After drying, manufacturers size and pack the wood-based activated carbon. These steps help keep the product the same and high quality for buyers.

Workers grind and sift the activated carbon to get the right size. Most of the product, about 88–90%, goes through a 200 mesh screen. This makes sure the carbon works well for filtering and adsorbing.

The activated carbon is packed in regular sizes like 25 kg bags and 500 kg big sacks. Some buyers want special packaging for their needs.

The packaging keeps the carbon safe from water and dirt. Strong bags and sacks protect the product during shipping and storage.

Quality checks make sure every batch meets the needed standards before it leaves the factory.

🛡️ Note: Keeping the size the same and packing well helps wood-based activated carbon arrive safe and ready for tough jobs.

Equipment & Quality Control

Key Equipment

Manufacturers use special machines to make high-quality activated charcoal. Each machine does a different job in the process. Some machines get raw materials ready. Others help make sure the final product is good. The right machines help make activated charcoal that works well every time.

Equipment Type | Role in Activated Carbon Manufacturing |

|---|---|

Rotary Kilns (Direct- and Indirect-fired) | These kilns are the main heating machines. They turn things like coal, coconut husks, and wood chips into high-quality activated charcoal. Rotary kilns can also make old carbon ready to use again. |

Material Handling Systems | These systems move materials and products around the plant quickly. |

Exhaust Handling Equipment | This equipment takes care of gases made during heating. It helps follow environmental rules and keeps workers safe. |

Product Cooling Equipment | Cooling units lower the temperature after heating. This makes activated charcoal safe to handle and helps meet product rules. |

Other machines are important too. Washing units clean out things that should not be there. Drying ovens take out water. Sizing machines crush and sift the product to get the right size. All these machines work together to help manufacturers make high-quality activated charcoal for many jobs.

🛠️ Tip: Keeping machines in good shape helps make activated charcoal that is always high quality.

Quality Control

Manufacturers check every batch of high-quality activated charcoal carefully. They test important things to make sure it is safe and works well. These tests show that the product can adsorb a lot and is safe for water, food, and factories.

Parameter | What It Means & Why It Matters | Typical Values / Notes | How It Is Measured |

|---|---|---|---|

This shows how well the charcoal adsorbs small things. A higher number means it works better. | At least 800 mg/g for liquids; up to 1700 mg/g for very pure water. | Standard tests like ASTM D4607-2014 | |

pH | This tells if the charcoal is acidic or basic. The right pH helps with adsorption and safety. | Wood: 2-4 (can change to 3-8); Coal: 9-12 (can change to 7-9); Coconut shell: 8-10 | ASTM D3838-2005(2011) |

Methylene Blue | This test shows how well the charcoal removes medium-sized organic things. | Wood-based is usually best. | Standard test methods |

Specific Surface Area | This tells how much surface area is in each gram. More area means better adsorption. | 300-1500 m²/g depending on material and process. | BET method |

Ash Content | This shows how much leftover stuff is not carbon. Less ash means cleaner, better charcoal. | Lower is better. | ASTM D2866-2011 |

Strength | This shows how hard it is to break or crush the charcoal. Stronger charcoal lasts longer. | Coconut shell-based is usually strongest. | ASTM D3802-10 |

Manufacturers also look for heavy metals, CTC value, and molasses value. These tests help make sure the high-quality activated charcoal is safe and does its job. Testing often and following strict rules helps keep the product trusted and high quality.

✅ Note: Careful quality checks help keep users safe and make people trust high-quality activated charcoal.

Activated Charcoal Forms & Applications

Granular

Granular activated charcoal is a very common type. Manufacturers make it into uneven pieces from 0.2 to 5 millimeters. This type has a good mix of surface area and low pressure drop. The pieces are strong and do not break easily. They can be used again after cleaning. Water plants use granular activated charcoal to clean drinking water. Fish tanks also use it to keep water safe and clear. It helps clean groundwater by trapping bad chemicals and heavy metals.

The table below shows the main features and uses of granular activated charcoal:

Form | Particle Size | Mechanical Strength | Adsorption Rate | Typical Applications |

|---|---|---|---|---|

Granular Activated Charcoal | 0.2–5 mm | High | Moderate | Drinking water, aquariums, groundwater |

Granular activated charcoal works well for systems that run all the time. Its toughness makes it good for big jobs.

Powdered

Powdered activated charcoal has very tiny pieces, smaller than 0.1 millimeter. This type has a lot of outside area, so it can grab things fast. Workers can add powdered activated charcoal right into water or waste streams. It is easy to use when quick fixes are needed for taste or smell problems. Factories use it in batches to treat certain pollutants. Wastewater plants add it to remove bad chemicals quickly.

The table below lists the main features and uses of powdered activated charcoal:

Form | Particle Size | Surface Area | Adsorption Rate | Typical Applications |

|---|---|---|---|---|

Powdered Activated Charcoal | <0.1 mm | Very High | Fast | Taste/odor control, wastewater, batch processes |

People pick powdered activated charcoal when they need quick results and easy use. Its small size helps when fast cleaning is needed.

Bead

Bead activated charcoal is made as small, round balls. Manufacturers use special methods to make these beads. The beads make little dust and are very strong. When packed in filters, they let water or air flow evenly. This helps remove bad stuff well. Bead activated charcoal is used to clean gases, like taking out VOCs from factory air. Air cleaning systems and gas treatment plants like beads because they are steady and easy to handle.

The table below compares bead activated charcoal with other special types:

Form | Shape | Mechanical Strength | Pressure Drop | Typical Applications |

|---|---|---|---|---|

Bead Activated Charcoal | Spherical | High | Low | VOC removal, air purification, gas treatment |

Extruded Activated Charcoal | Cylindrical | High | Low | Industrial gas, VOC removal |

Honeycomb Activated Charcoal | Honeycomb | Very High | Very Low | Automotive, HVAC, energy-efficient gas treatment |

Bead activated charcoal gives steady results in tough places. Its round shape and strength make it great for cleaning air and gases.

Making activated charcoal in these shapes helps meet many industry needs. Each type has special benefits for jobs like water cleaning or air filtering.

Common Uses

Activated charcoal is used in many different industries. Its tiny holes help it trap and remove many kinds of pollution. Many companies use activated charcoal for cleaning and safety.

The biggest use for activated charcoal is in water cleaning. Water plants use it to take out chlorine, heavy metals, and bad chemicals from drinking water. Home filters also use activated charcoal to make water taste better and smell fresh. Factories that clean dirty water use it before putting water back into rivers or lakes.

Cleaning air and gases is another big job for activated charcoal. Factories and big buildings use it to catch bad smells, VOCs, and dangerous gases like hydrogen sulfide and radon. Hospitals and labs use air cleaners with activated charcoal to keep the air safe inside.

People who clean up the environment use activated charcoal for spills and dirty water. It can grab onto toxic chemicals, so it is important during chemical spills. Mining companies use activated charcoal to get gold and other metals from rocks.

Food and drink makers use activated charcoal in many ways. They use it to make juices, sweeteners, and oils clear and pure. It also helps take away bad tastes and smells. Winemakers and juice companies use it to make their products look and taste good.

Doctors use activated charcoal to help people who swallow poison or take too much medicine. Hospitals give it to patients because it sticks to harmful things in the stomach. Some medicines for upset stomachs and diarrhea also have activated charcoal.

Farmers use activated charcoal for animals and crops. They add it to animal food to help with digestion and lower toxins. It can also be used as a bug killer and to clean animal homes.

Many beauty and personal care products have activated charcoal. Toothpaste, shampoo, and face masks use it to soak up dirt and extra oil from skin and hair.

The table below shows the main ways activated charcoal is used in different jobs:

Industry/Application Area | Common Uses of Activated Charcoal |

|---|---|

Water Purification | Removal of chlorine, heavy metals, taste and odor compounds, organic pollutants |

Air and Gas Purification | VOC removal, odor control, hydrogen sulfide and radon removal |

Environmental Remediation | Spill cleanup, groundwater remediation, wastewater treatment |

Mining | Precious metal recovery (gold) |

Food and Beverage Processing | Decolorization, deodorization, purification of juices, oils, sugars |

Medical | Treatment of poisoning, overdoses, indigestion, diarrhea |

Agriculture | Livestock feed additive, pesticide, disinfectant, winemaking |

Cosmetics | Shampoos, toothpastes, face masks |

Industrial Gas Purification | Removal of acid gases, ammonia, aldehydes, mercury, radioactive iodine |

💡 Tip: Activated charcoal works best when you pick the right type for the job. Its shape and pore size matter for each use.

Comparing Activated Carbon Manufacturing Methods

Pros & Cons by Material

Manufacturers pick raw materials for activated carbon based on how well they work, how much they cost, and what they will be used for. Each material has good points and bad points.

People in the coconut shell activated carbon business like coconut shells because they are hard and have lots of tiny pores. This kind is great for cleaning water and treating dirty water. Coconut shell activated carbon lasts a long time and does not wear out fast. But, if there are not enough coconut shells, the price can go up.

Coal-based activated carbon has many different pore sizes. It is good for cleaning water in factories and treating wastewater. But, getting and using coal can hurt the environment.

Wood-based activated carbon has lots of medium-sized pores. It is very good at removing color and adsorbing gases. Wood grows back, so it is renewable. But, this kind of activated carbon is not as strong and can break more easily.

The table below shows the main good and bad points:

Material | Pros | Cons | Typical Use |

|---|---|---|---|

Coconut Shell | High hardness, long life, microporous | Supply issues, higher cost | Water treatment, wastewater |

Coal | Wide pore range, high adsorption | Environmental impact, variable quality | Water, wastewater treatment |

Wood | Renewable, good mesopores, lower cost | Lower strength, variable adsorption | Decolorization, gas, wastewater |

Picking the right material helps manufacturers make activated carbon that works best for cleaning water and wastewater.

Cost & Efficiency

How much it costs to make activated carbon and how well it works depends on the material, the process, and how much energy is used. The coconut shell activated carbon business often pays more for raw materials, but the product lasts longer, so it saves money over time. Coal and wood cost less at first, but they might need to be replaced more often.

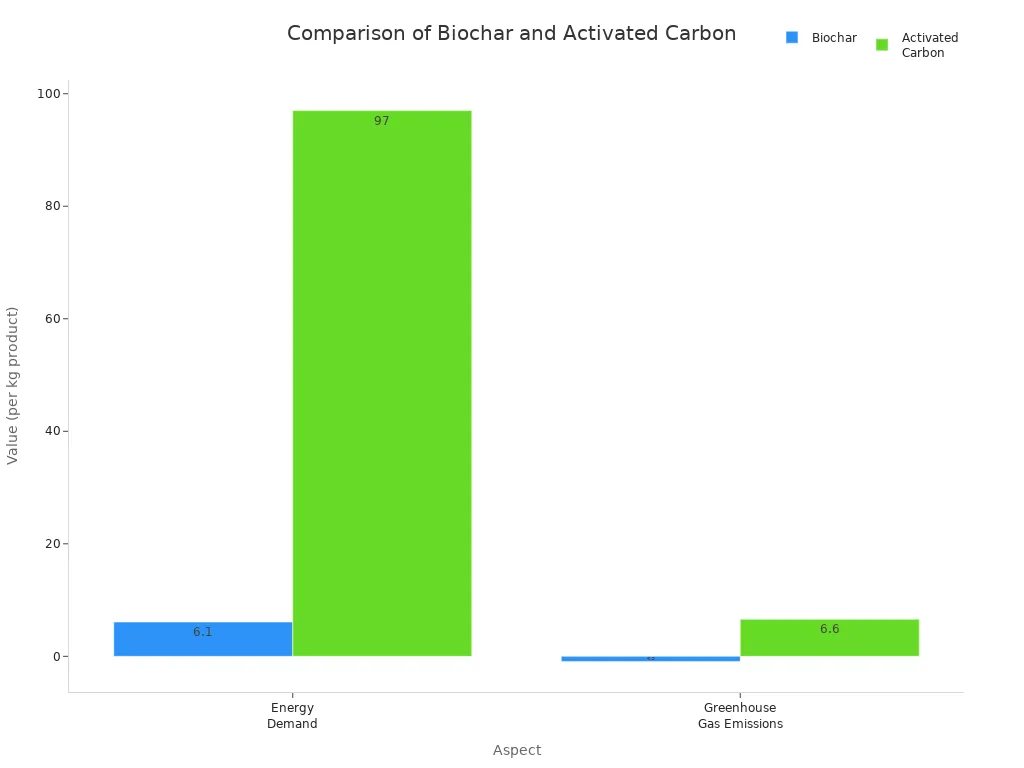

The table below compares biochar and activated carbon:

Aspect | Biochar | Activated Carbon |

|---|---|---|

Energy Demand | 97 MJ/kg | |

Greenhouse Gas Emissions | -0.9 kg CO2 eq/kg | 6.6 kg CO2 eq/kg |

Adsorption Efficiency | Comparable or lower (depends on type) | Generally higher (high iodine value) |

Adsorption Cost | Lower for Cr and Zn removal; comparable for Pb and Cu | Higher overall cost |

Environmental Impact | Lower global warming potential and energy demand | Higher environmental impact |

High-quality activated carbon with an iodine value over 800 mg/g works better and lasts longer. It costs more at first, but you do not have to replace it as often, so you save money later. Manufacturers can spend less by using waste materials or making the process better.

Environmental Impact

Caring for the environment is important when picking how to make activated carbon. The coconut shell activated carbon business helps the planet by using waste that grows back. Making coal-based activated carbon uses more energy and makes more greenhouse gases, which is bad for the environment. Wood-based activated carbon is renewable, but cutting down too many trees can hurt nature if not done carefully.

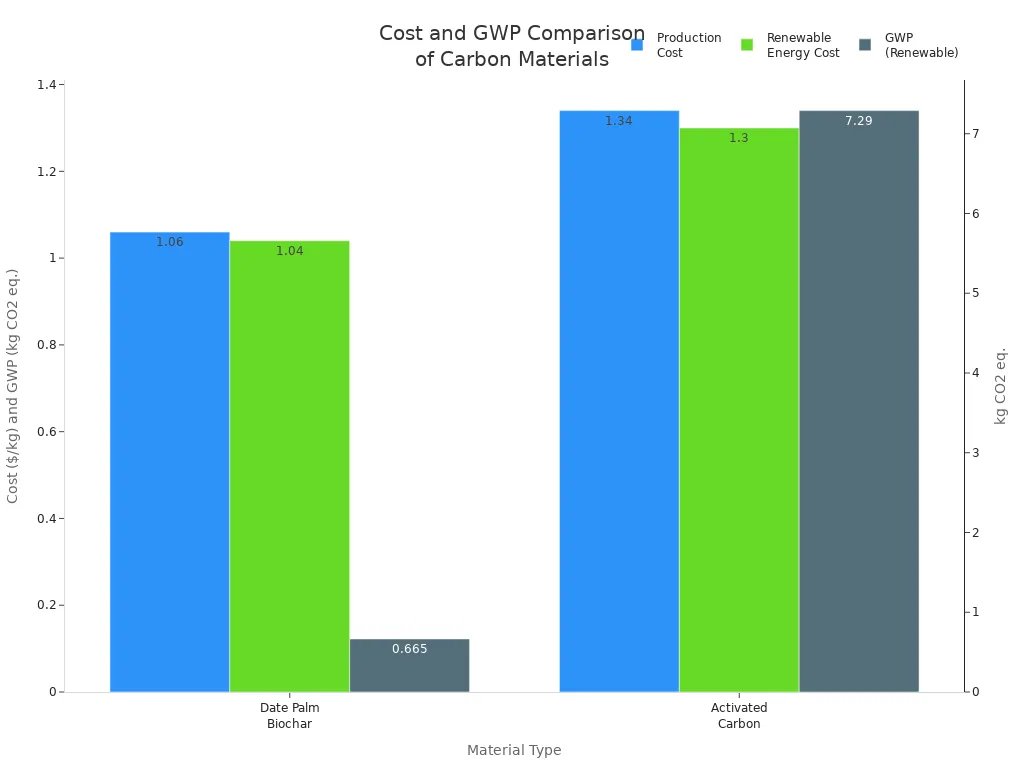

Using green energy and waste materials can help lower the global warming effect of both biochar and activated carbon. The chart below shows that biochar made from date palm waste costs less to make and is better for the environment than activated carbon, especially when using green energy.

Manufacturers who care about the environment can save money and help the planet by picking greener materials and energy.

Practical Tips

Manufacturers can use some easy tips to make high-quality activated carbon. These tips help make the process safer and better. They also help save money.

1. Choose the Right Raw Material

Pick raw materials that fit the job you want.

Coconut shells make hard carbon with tiny pores for cleaning water.

Coal gives many pore sizes for factories.

Wood makes carbon with medium pores for removing color and gases.

2. Control Process Parameters

Watch the temperature and heating speed during carbonization and activation.

Use good sensors so things do not get too hot or too cold.

Keep the activation time the same to make even pores.

3. Maintain Equipment Regularly

Check rotary kilns, washing machines, and dryers for damage.

Clean machines that move materials to stop dirt from mixing in.

Do regular check-ups to keep machines working longer and avoid stops.

4. Prioritize Quality Control

Test every batch for iodine value, ash, and size.

Use trusted methods like ASTM or ISO for good results.

Write down test results to spot problems early.

5. Optimize Washing and Drying

Wash with clean water and gentle acids to clean well.

Dry the product fully so it does not have too much water.

Store activated carbon in closed containers to keep it dry.

6. Focus on Safety and Environmental Impact

Give workers safety gear when they use chemicals or hot items.

Use machines to handle exhaust and keep air clean.

Reuse washing water and use green energy if you can.

7. Adapt to Market Needs

Make activated carbon in different shapes like granular, powdered, or bead.

Change the size and packaging to match what customers want.

Learn about new rules and trends in the industry.

💡 Tip: Small changes in how you run things can make the product much better and save money.

Step | Key Action | Benefit |

|---|---|---|

Raw Material Choice | Pick what fits the job | Works better |

Process Control | Watch heat and time | Same quality every time |

Equipment Care | Check and fix machines | Fewer problems |

Quality Checks | Test each batch | Product you can trust |

Safety Measures | Use safety gear | Fewer injuries |

By following these tips, manufacturers can make activated carbon that is high quality. They can also spend less and help the environment.

Manufacturers make activated carbon by doing several main steps. These steps are carbonization, activation, washing, drying, sizing, and packaging. Each raw material, like coconut shell, coal, or wood, needs its own way and special machines. Picking the right raw material and watching the process closely makes the product better. People who want to make activated carbon should look for local materials and buy good machines.

Note: Learning about new rules and testing ways helps keep activated carbon high quality for all uses.

FAQ

What raw materials can manufacturers use to produce activated carbon?

Manufacturers use coconut shells, coal, wood, or nut shells. Each one makes different pores and has special adsorption abilities. The choice depends on what is nearby, the price, and how it will be used. Coconut shells are very hard. Coal and wood give different pore sizes for many jobs.

How does physical activation differ from chemical activation?

Physical activation uses steam or carbon dioxide with high heat. Chemical activation uses acids or salts at lower heat. Physical methods make smaller pores and need less washing. Chemical methods make even pores and more surface area but need lots of washing to clean out chemicals.

What equipment do manufacturers need for activated carbon production?

Manufacturers use rotary kilns to heat the material. Washing units clean the product. Drying ovens take out water. Sizing machines control the size of the particles. Material handling systems and exhaust equipment help keep things safe and running well. Keeping machines in good shape helps make the same quality every time.

Why is quality control important in activated carbon manufacturing?

Quality control checks if activated carbon is safe and works well. Manufacturers test iodine value, pH, ash, and size. Good quality keeps users safe and makes customers trust the product. Regular tests help find problems early and keep performance high.

What safety precautions should workers follow during production?

Workers wear safety gear when using chemicals or hot things. They check oxygen in storage to stop dangers. Manufacturers use exhaust systems to handle gases. Training and safety rules help lower risks and keep everyone safe at work.

Can activated carbon be reused after application?

Activated carbon can sometimes be used again. Manufacturers use heat or chemicals to bring back its adsorption power. If it can be reused depends on what it cleaned and where it was used. Good handling helps it last longer and saves money.

What are the main applications for activated carbon?

Activated carbon takes out pollution from water, air, and gases. It cleans food and drinks, helps treat poisoning, and is used for cleaning up the environment. Manufacturers change the pore size and form—granular, powdered, or bead—to fit each job.

How do manufacturers choose the right activated carbon for each application?

Manufacturers look at pore size, hardness, and how much it can adsorb. They pick the form—granular, powdered, or bead—that fits the job. Water cleaning needs hard carbon with small pores. Air cleaning works well with bead or extruded forms. The job decides which type to use.