You use granular activated carbon to clean water by taking out bad stuff. It works because it has lots of tiny holes that catch things through adsorption. This makes it very good for cleaning water and in factories. New studies say it can remove up to 87% of some chemicals, even tough ones like PFAS. Many water companies pick this way because it keeps drinking water safe and clean.

Key Takeaways

Granular activated carbon cleans water by trapping bad stuff. This happens through a process called adsorption. The structure of activated carbon has many tiny pores. These pores help it hold lots of unwanted molecules. The raw material used for activated carbon is important. It changes how strong the carbon is. It also affects what contaminants it can remove. Pore size matters a lot. Different pore sizes catch different contaminants. Pick carbon based on what you want to remove. Water should touch the carbon for a long time. Slow water flow helps remove more contaminants. Change or clean your activated carbon filters often. This keeps them working well. It also stops bacteria from growing. Activated carbon makes water taste and smell better. That is why people use it in home water filters. In factories, activated carbon removes harmful pollutants. This keeps people and the environment safe.

Granular activated carbon

Definition

Activated carbon comes in different shapes and sizes. Granular activated carbon is special because of its small, hard pieces. It is found as granules or as extruded forms. These pieces are bigger than powdered activated carbon. They have less outside surface but are easier to use in filters. People use granular activated carbon in big water plants and factories. It works well in large systems and can be cleaned and used again.

Here is a table that shows the usual forms and sizes you might see:

Property | Description / Range |

|---|---|

Physical Forms | Granular or extruded |

Typical Sizes | 8×20, 20×40, 8×30 (liquid phase); 4×6, 4×8, 4×10 (vapor phase) |

Particle Size | 1–6 mm diameter; length about 0.7 to 4 times diameter |

Structure

The way activated carbon is built makes it work so well. If you look at granular activated carbon under a microscope, you will see lots of tiny holes called pores. These pores come in many sizes, like micropores and mesopores. The inside of the carbon has a huge surface area. Scientists use BET surface area analysis to measure this. The big surface area and many pore sizes help activated carbon trap many kinds of bad stuff.

Tip: More pores and more surface area mean activated carbon can clean water and air better.

Properties

Activated carbon has some important features that help it remove things we do not want. The most important feature is its many pores, which give it a large surface area for adsorption. This lets activated carbon hold many molecules at the same time. Its pore sizes can be changed to catch certain contaminants. The different sizes of pores help it trap both organic and inorganic contaminants. Another key feature is the surface functional groups, like carboxyl groups. These groups help with chemical reactions and make it easier for microbes to break down natural organic matter.

People use activated carbon in water treatment to take out chemicals, bad tastes, and smells. In factories, it helps clean up waste and air pollution. Because of its special structure and features, activated carbon is one of the best ways to keep water and air clean.

Activated carbon production

Raw materials

Activated carbon can be made from many things. Each thing gives the carbon special features. The most used sources are coal, wood, coconut shells, and peat. Some factories use leftovers like petroleum coke, sawdust, or bark. Picking a raw material changes how strong the carbon is. It also changes the pore size and how well it adsorbs.

Here is a table that lists some popular raw materials and what they are:

Raw Material | Description |

|---|---|

Bituminous Coal | A common precursor for activated carbon production. |

Anthracite | A high carbon content coal used in GAC. |

Subbituminous Coal | Another type of coal used in the production. |

Lignite | A lower grade of coal used as a precursor. |

Wood | Various types of wood can be used. |

Coconut Shells | A popular source for high-quality GAC. |

Peat | An organic material used in some GAC production. |

Coconut shells are often used to make commercial activated carbon. Bituminous coal is also picked a lot. Factories sometimes use lignite or petroleum coke for certain jobs. Sawdust and bark, which come from wood, can be used too.

Tip: The raw material you pick changes how well the carbon works for different uses.

Activation process

After picking a raw material, you need to make it into activated carbon. This is done by a special step called activation. First, you heat the raw material without oxygen. This is called carbonization. It takes away things you do not want and leaves mostly carbon. Then, you activate the carbon to make lots of pores. These pores help the carbon adsorb things well.

There are different ways to activate carbon. Here are the main steps:

Heat the raw material at high heat with no oxygen (carbonization).

Add a binder if you need to shape the material before activation.

Use steam or carbon dioxide at high heat to activate the carbon (physical activation).

Use chemicals like zinc chloride, phosphoric acid, or potassium hydroxide for chemical activation.

The activation step changes the pores inside the carbon. High heat opens more pores and makes more surface area. Using the right particle size, like 20-40 mesh, helps the activating agents go deeper. This makes the carbon better at catching bad stuff.

How you make activated carbon changes how well it works. The raw material and activation method decide the strength, pore size, and adsorption power. By controlling these steps, you get carbon that works for water, air, or factories.

Adsorption

Granular activated carbon uses adsorption to clean things. Adsorption means the carbon grabs and holds unwanted molecules. This happens on the surface and inside the tiny pores. Granular activated carbon works well because it traps contaminants in two ways. It uses both physical and chemical adsorption.

Physical adsorption

Physical adsorption is the main way it removes contaminants. Molecules stick to the surface without making chemical bonds. Granular activated carbon has many pores and a big surface area. This helps it trap more molecules.

Pore size

The pores come in different sizes. There are micropores, mesopores, and macropores. The size of the pores decides what gets trapped. Big molecules fit in mesopores and large micropores. Small micropores catch tiny molecules. The pore size mix decides what contaminants get removed. If you want to remove certain pollutants, pick carbon with the right pore sizes.

Surface area

Activated carbon has a very large surface area. This gives many spots for molecules to stick. More surface area means better adsorption. Using activated carbon in filters helps catch more contaminants. Scientists use tests to measure the surface area. Activated carbon can have thousands of square meters per gram. This big surface area is important for adsorption.

Note: Pore size and surface area together help activated carbon trap many contaminants.

Chemical adsorption

Chemical adsorption happens when molecules react with the carbon’s surface. Special groups on the surface help with this.

Chemical interactions

The surface has groups like carboxyl, hydroxyl, and phenol. These groups attract and hold certain molecules. For polar contaminants, these groups make strong bonds. They use hydrogen bonding, van der Waals forces, and electrostatic interactions. Treating carbon with chemicals can change these groups. This can help it remove more pollutants. Sometimes, surface chemistry is more important than pore size. For example, to remove arsenate, the type and amount of oxygen groups matter a lot.

Surface groups on activated carbon help by:

Making it better at adsorbing polar molecules.

Helping with non-polar molecules if the surface is hydrophobic.

Increasing adsorption after treatments like acid washing or oxidation.

Granular activated carbon uses both physical and chemical adsorption. The pores trap molecules. The surface groups help hold them. This makes activated carbon great for cleaning water and air.

Tip: For the best results, choose activated carbon with the right pore size and surface chemistry for your needs.

Contaminant removal

Granular activated carbon can take out many bad things from water and air. Its special shape and big surface area help it clean up harmful stuff. You can use activated carbon to get rid of organic chemicals, make water taste and smell better, and deal with tough factory pollution.

Organic chemicals

Organic chemicals get into water from things like pesticides, spills, or home products. Activated carbon takes these chemicals out by adsorption. The pores in activated carbon catch the molecules and stop them from going through the filter. This keeps you safe from toxins and makes your water safer.

Here is a table that shows how well activated carbon removes some pesticides:

Pesticide Class | Removal Percentage (%) |

|---|---|

Acetanilide Pesticides | 72 – 98 |

Triazine Pesticides | 47 – 62 |

Pendimethalin | > 99 |

Activated carbon also takes out other organic chemicals, like:

Pesticides (such as acetanilide and triazine)

Volatile Organic Compounds (VOCs)

Haloalkanes (like MTBE)

Acetone

PFAS (including PFOA and PFOS)

Activated carbon can remove more than 98% of haloalkanes and MTBE. It also takes out about 47% of acetone. This shows that activated carbon works well to protect you from toxins and organic pollution.

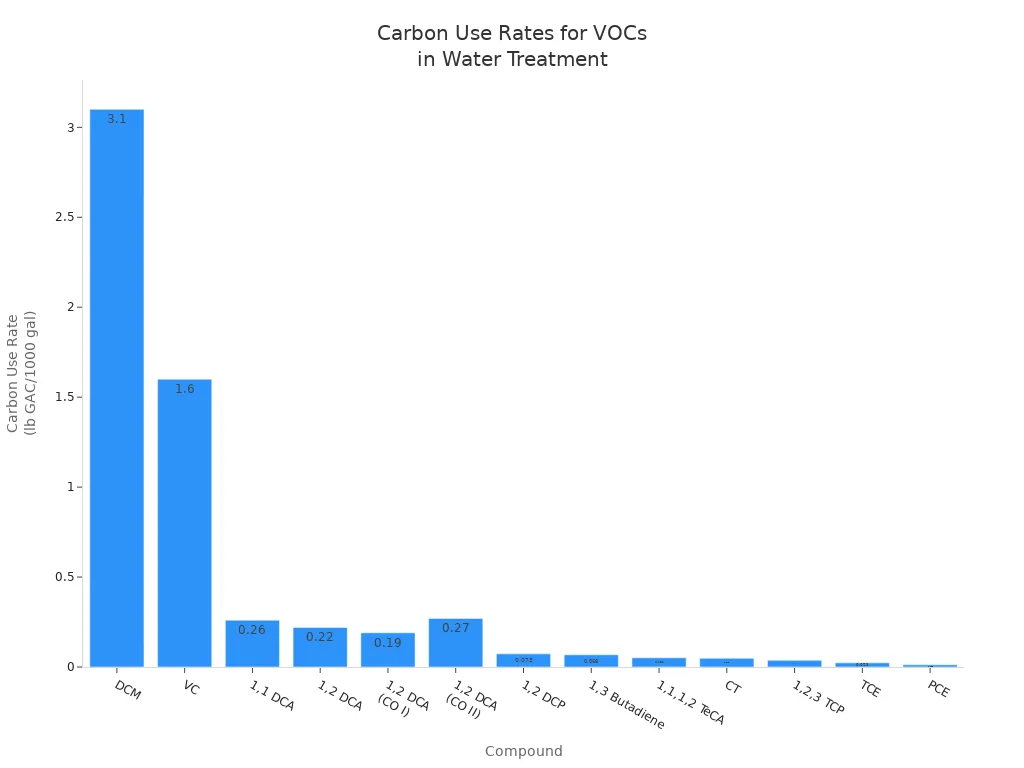

Water treatment plants use activated carbon to remove many VOCs. The chart below shows how much activated carbon is needed to take out different VOCs from water:

You can see that activated carbon works for many chemicals. It helps keep your water safe and clean.

Taste, odor, color

Sometimes your tap water tastes, smells, or looks strange. These problems often come from organic compounds or natural stuff. Activated carbon fixes these problems by catching the molecules that cause them.

Activated carbon is good at grabbing organic compounds and non-polar things. These are the main reasons for bad taste and smell. When you use activated carbon, it holds these molecules on its surface. This makes your water taste better and look clearer.

Tip: If you want fresh and clean water at home, use activated carbon filters to get rid of bad tastes, smells, and colors.

You can trust activated carbon to make your drinking water better. It works in labs and in real life. Many water plants use activated carbon for this reason.

Industrial contaminants

Factories put many bad things into water and air. Activated carbon helps take out these harmful things before they reach your home or nature. It uses different pore sizes to catch many kinds of toxins.

Here is a table that shows how activated carbon catches different industrial contaminants:

Contaminant Type | Adsorption Mechanism |

|---|---|

Micropore Adsorption | Best for adsorbing smaller molecules, such as chlorine and VOCs. |

Mesopore Adsorption | Suitable for removing larger organic molecules, like color, taste, and some heavy metals. |

Macropore Adsorption | Used for the removal of larger particles or complex organic pollutants. |

Activated carbon uses micropores for small things like chlorine and VOCs. Mesopores help remove bigger organic molecules and some metals. Macropores catch large particles and complex pollution.

Activated carbon keeps you safe from factory toxins by trapping them. You can use it in factories, water plants, or even at home if you live near factories.

Note: Activated carbon gives you a simple and strong way to take out many kinds of bad things from water and air.

Performance factors

Pore size

When picking granular activated carbon, look at pore size. The size of the pores decides what it can catch. There are three main pore types in granular activated carbon. These are micropores, mesopores, and macropores. Each type is best for certain molecules.

Micropores (less than 2 nanometers): These catch small molecules like chlorine and many organic chemicals.

Mesopores (2–50 nanometers): These trap medium-sized molecules, like some pesticides and things that cause taste or smell.

Macropores (greater than 50 nanometers): These help big molecules move into the carbon. This lets them reach the smaller pores inside.

To remove a certain contaminant, match the pore size to the molecule’s size. For example, micropores are good for catching VOCs. Mesopores help with bigger organic compounds. Having a mix of pore sizes gives the best results.

Tip: More micropores help remove small contaminants. More mesopores help with bigger molecules.

Contact time

Contact time means how long water or air touches the activated carbon. Longer contact time lets more contaminants stick to the carbon. If water moves too fast, some bad stuff might get through. Make sure water flows slowly enough for the carbon to work.

“Empty bed contact time” (EBCT) is a way to measure this. EBCT tells you how long water stays in the carbon bed. Most water systems use an EBCT of 10 to 20 minutes. If you want better removal, increase the contact time. This gives the carbon more chances to catch contaminants.

Short contact time: Removes less, especially tough contaminants.

Long contact time: Removes more, but needs a bigger filter.

Note: For the best results, balance flow rate and contact time.

Temperature

Temperature changes how well granular activated carbon works. Warmer water makes molecules move faster. This helps them reach the carbon more quickly. Adsorption happens faster at higher temperatures. But how much carbon can hold depends on the contaminant.

Here is a table that shows how temperature affects adsorption for different pollutants:

Pollutant | Temperature Effect on Adsorption Capacity | Notes |

|---|---|---|

MIB | No significant effect | Equilibrium adsorption capacity not significantly affected by temperature. |

Geosmin | Decreased at 4 °C | Similar behavior at 10 °C and 20 °C, but decreased at lower temperatures. |

Atrazine | Variable | Capacity decreased in warmer tap water; increased in warmer water with NOM. |

Multi-solute | Complex interaction | Competitive adsorption complicates temperature effects. |

Kinetics | Enhanced with temperature | Adsorption rate increases with temperature according to the Arrhenius equation. |

Some pollutants, like MIB, do not change much with temperature. Others, like geosmin, are removed less when it is cold. Atrazine acts differently depending on the water and what else is in it. In general, higher temperatures make adsorption happen faster. But the total amount removed can go up or down.

Remember: Warmer water can make carbon work faster, but it does not always mean better removal for every contaminant.

pH

It is important to check the pH when using granular activated carbon. pH tells you if water is acidic or basic. The pH level affects how well the carbon can trap contaminants. If water is too acidic or too basic, the carbon may not work well.

When pH is low, the carbon’s surface gets more positive. This helps it attract and hold negative contaminants, like some metals or chemicals. When pH is high, the carbon’s surface gets more negative. This helps it catch positive contaminants. Some organic chemicals stick best to carbon when pH is close to 7.

Some contaminants change their shape or charge at different pH levels. This can make them easier or harder to remove. For example, chlorine is removed better at low pH. Ammonia is removed better at high pH. To get the best results, test your water’s pH and change it if needed.

Tip: Most water treatment works best when pH is between 6 and 8. This range helps activated carbon remove the most contaminants.

Saturation

Saturation means the carbon is full of contaminants. When this happens, the carbon cannot trap more bad stuff. You need to watch for signs that your filter is full.

As carbon fills up, it removes fewer new contaminants. Big organic molecules can block the pores inside the carbon. When this happens, small molecules cannot get inside to be trapped. Over time, the filter works less well.

Here is a table that shows what happens as granular activated carbon gets full:

Aspect | Description |

|---|---|

Saturation Impact | As GAC fills up, it cannot adsorb more contaminants. |

Pore Blockage | Big organic molecules can block pores, stopping smaller ones from getting in. |

Effective Pore Size Range | |

Overall Capacity Decrease | When full, the carbon cannot remove as many contaminants. |

The best pores for removing natural organic matter (NOM) are between 5 and 10 nanometers. When these pores fill up, the carbon cannot hold as much. If your water starts to taste or smell bad again, your filter might be full.

Note: Change or clean your activated carbon often to keep your water safe and clean.

Applications

Water treatment

Activated carbon is used in many water systems. Granular activated carbon helps keep drinking water safe. Filters use it to take out bad chemicals and make water taste better. Big water plants have beds filled with activated carbon. These beds clean thousands of gallons every day.

Sometimes, activated carbon columns work with other methods like reverse osmosis. This helps remove even more bad stuff. Some cities use special units with activated carbon for emergencies, like PFAS spills.

Here are some ways activated carbon helps in water treatment:

It removes pesticides, endocrine disruptors, and medicine leftovers.

It makes water taste and smell better.

It controls disinfectant by-products.

Activated carbon works by adsorption. It traps unwanted molecules in its pores. This keeps your water clear and fresh. You get cleaner water every time you use the tap.

Tip: Water companies pick activated carbon because it can catch many kinds of contaminants.

Air filtration

Activated carbon is also used to clean air. Its many tiny pores help trap odors, gases, and VOCs. When air goes through a filter with activated carbon, pollutants stick to the surface. This is called adsorption.

Activated carbon is often used with HEPA filters. HEPA filters catch dust and particles. Activated carbon grabs harmful gases and VOCs that HEPA cannot. This gives you cleaner air at home, work, or in factories.

Activated carbon takes away smells from kitchens and bathrooms.

It helps control smoke and chemical fumes in factories.

You can use it in air purifiers to lower allergens and make indoor air better.

Note: Activated carbon makes air filters work better against hidden pollutants.

Industrial use

Factories use activated carbon for many jobs. It helps make products better and keeps the environment safe. Factories use it to clean water, air, and to recover valuable materials.

Here is a table that shows how factories use granular activated carbon and what it removes:

Contaminants Targeted | |

|---|---|

Reducing undesirable taste, odor, and color | Organic compounds, disinfection byproducts (THMs) |

Improving drinking water safety | Chlorinated solvents, industrial pollutants, pesticides |

Adsorbing heavy metals like lead and mercury | Heavy metals |

Activated carbon helps factories follow safety rules. It removes toxic chemicals before they get into nature. It is also used to recover gold or clean chemicals. Its strong adsorption power makes it a top choice for many factory jobs.

Remember: Activated carbon keeps people and the planet safer in factories.

Household use

You might use granular activated carbon at home every day. Many water filters use GAC to clean your tap water. When you pour water into a pitcher filter, GAC starts working. Faucet filters and built-in filters also use GAC.

GAC traps chemicals in its tiny pores. This helps remove things that make water taste or smell bad. For example, GAC is great at removing chlorine. Chlorine can make tap water taste strong and unpleasant. GAC also takes out hydrogen sulfide. Hydrogen sulfide makes water smell like rotten eggs. If your water tastes better after filtering, GAC is the reason.

Here are some ways you use GAC at home:

Pitcher filters

Faucet filters

Under-sink systems

Refrigerator dispensers

Shower filters

These products use GAC to catch certain contaminants. You will notice the biggest change with organic chemicals, chlorine, and hydrogen sulfide. These are the main reasons for bad taste and smell in water.

Tip: If your water tastes or smells weird, try a filter with granular activated carbon.

GAC cannot remove everything. Some things, like iron and nitrate, go through GAC filters. If you want to remove these, you need a different filter. Reverse osmosis can help with nitrate. Always check what your filter can and cannot do before buying.

Here is a table that shows how GAC works compared to other methods:

Contaminant | Removed by GAC? | Notes |

|---|---|---|

Chlorine | Yes | Removes taste and odor |

Hydrogen sulfide | Yes | Removes rotten egg smell |

Organic chemicals | Yes | Removes many, but not all |

Iron | No | Needs special filter |

Nitrate | No | Needs reverse osmosis or ion exchange |

You should change your GAC filter often. The pores fill up and stop trapping contaminants. Most companies say to change filters every two to six months. This depends on how much water you use.

GAC helps in other places at home too. Some air purifiers use GAC to remove smells and chemicals from the air. Aquarium filters use GAC to keep fish tanks clean and clear.

Maintenance

Lifespan

You want your filter to last as long as possible. The lifespan of granular activated carbon depends on how you use and care for it. If you install it the right way, you help it work better and last longer. Soaking the carbon before use removes trapped air and lets water flow through all the pores. Backwashing your system often keeps the carbon clean and working well. Using pretreatment steps, like removing big particles before water reaches the carbon, also helps. Many water treatment plants use two carbon beds in a row. This setup lets you watch for “breakthrough,” which is when contaminants start to get through the first bed. By switching beds at the right time, you get the most out of your carbon.

Soak the carbon before use to remove air.

Backwash the system regularly.

Use pretreatment to remove large particles.

Operate two beds in series and monitor for breakthrough.

Tip: Good care and setup can make your filter last much longer.

Regeneration

When your carbon gets full, you can sometimes bring it back to life. This process is called regeneration. There are several ways to do this. The most common method is thermal regeneration, where you heat the carbon to very high temperatures. This method works well but can cause you to lose 10% to 30% of your carbon each time. It can also create harmful gases like sulfur dioxide. Other methods include electrochemical, Fenton-like oxidative, microwave, and ultrasonic regeneration. These may help you save more carbon and reduce pollution.

Researchers have found that heating spent carbon with steam at 800°C can restore most of its ability to adsorb contaminants. However, this process can change the size of the pores inside the carbon. You may get more medium-sized pores but lose some of the smallest ones. This change can make it harder for the carbon to catch small molecules.

Thermal regeneration: Most common, but causes carbon loss and pollution.

Steam at high heat: Restores adsorption but changes pore sizes.

Other methods: May save more carbon and reduce harmful by-products.

Note: Regeneration helps you reuse carbon, but it may not work as well as new carbon for all contaminants.

Replacement

You need to replace your carbon filter on a regular schedule. If you wait too long, the filter can fill up and stop working. Old filters can let water flow through channels, which means some water skips the carbon and stays dirty. Bacteria can also grow in old filters, making your water unsafe. The amount of carbon in your filter and how long water stays in contact with it both affect how well it works. By changing your filter on time, you keep your water clean and safe.

Replace filters before they get full.

Prevent channeling and keep removal rates high.

Stop bacteria from building up in the filter.

Tip: Set a reminder to change your filter so you always have clean water.

Now you know how granular activated carbon works. It traps unwanted stuff by using adsorption. Its special structure and how it is made give it a big surface area. You can use it to clean water at home, in factories, or in big plants. After treatment, water tastes better and smells fresher. It also makes water safer because it works well. You will find granular activated carbon anywhere clean water is important.