You use the impregnation process in activated carbon manufacturing to add special chemicals or substances to the carbon. This step changes the surface of the carbon. It helps the carbon capture certain pollutants better. Many industries now use impregnation activated carbon. It works well to remove contaminants from air and water. The table below shows how the process improves the properties of Impregnated Activated Carbon:

Aspect | Description |

|---|---|

Surface Modification | The process changes the carbon’s surface for better performance. |

Adsorption Capacity | You get a higher ability to trap unwanted substances. |

Selectivity | It helps you target specific pollutants. |

Regeneration Ability | You can reuse the carbon more easily. |

Key Takeaways

The impregnation process makes activated carbon better by adding chemicals. These chemicals help it catch more pollutants.

Impregnated activated carbon works well to remove hard contaminants. It can take out things like mercury, ammonia, and hydrogen sulfide.

Picking the right chemicals for impregnation is very important. Different pollutants need special chemicals to work best.

The carbon must be cleaned and dried before impregnation. This step is needed for the process to work well.

Activated carbon comes in different forms, like granular or pellet. Each type is used for certain jobs, so pick the right one.

Quality control checks make sure the impregnated carbon works well. It is important to check if it is even and effective.

After impregnation, steps like drying and curing are done. These steps help keep the chemicals on the carbon and make it last longer.

Testing and watching the process often helps stop problems. This also makes sure the activated carbon is high quality.

Impregnation Activated Carbon Basics

What Is Impregnated Activated Carbon

You use impregnated activated carbon to clean air, water, or soil. This carbon has special chemicals on its surface. These chemicals help trap certain pollutants better. Regular activated carbon cannot remove some tough pollutants. Impregnated activated carbon can catch things like mercury, ammonia, or hydrogen sulfide. You see it used in cleaning up the environment, in factories, and in water plants.

Tip: You can pick different chemicals for different pollutants. Some common ones are metals, acids, alkalis, and oxidants. Here are some examples:

Silver: helps stop bacteria and supports oxidation.

Copper: works for ammonia and cyanide.

Manganese: removes iron and manganese from water.

Sodium hydroxide and potassium hydroxide: trap acidic gases.

Phosphoric acid and sulfuric acid: catch alkaline gases.

Potassium permanganate and hydrogen peroxide: help with oxidation of organic compounds.

Composite mixes: use several chemicals for hard pollution problems.

Forms and Types

You can pick granular or pellet forms of impregnated activated carbon. Each form works best for certain jobs. Granular activated carbon has bigger pieces. You use it in fixed beds for water or soil cleanup. Pellet activated carbon has small, even pieces. You use pellets for cleaning air or controlling emissions.

Here is a table that shows how granular and pellet activated carbon are different:

Property | Granular Activated Carbon | Pellet Activated Carbon |

|---|---|---|

Particle Size | Bigger pieces, good for fixed beds | Even, small pieces, good for gas cleaning |

Specific Surface Area | Medium surface area | A bit less surface area |

Adsorption Capacity | Medium, good for bigger pollutants | High, works well for small pollutants |

Regeneration Capacity | High, can be used many times | Good, but can break down |

Useful Life | Lasts a long time, good for long use | Shorter life, depends on flow |

Cost Factors | Medium cost, good for big jobs | Higher cost, good for fast jobs |

Key Benefits

Impregnated activated carbon gives you many benefits. The main one is better trapping of certain pollutants. You can target gases, metals, or organic compounds that regular activated carbon misses. You also get better selectivity, so you only trap what you want. This means you use less material and get better results.

You can reuse impregnated activated carbon more easily because the chemicals help with regeneration. It also lasts longer in many uses. Here are some common ways to use impregnated activated carbon:

Application Type | Description |

|---|---|

Soil and Groundwater Remediation | Used to trap pollutants from dirty sites. |

Emission Control | Helps control harmful gases in factories. |

Targeting Specific Odors | Works well for smells like hydrogen sulfide and ammonia. |

Note: Always pick the right type of impregnated activated carbon for your needs. This helps your filter work better and last longer.

Pre-Treatment Steps

Before you begin the impregnation activated carbon process, you must get the carbon ready. Good preparation helps you make a better final product. You need to check particle size, surface area, and clean and dry the carbon.

Particle Size

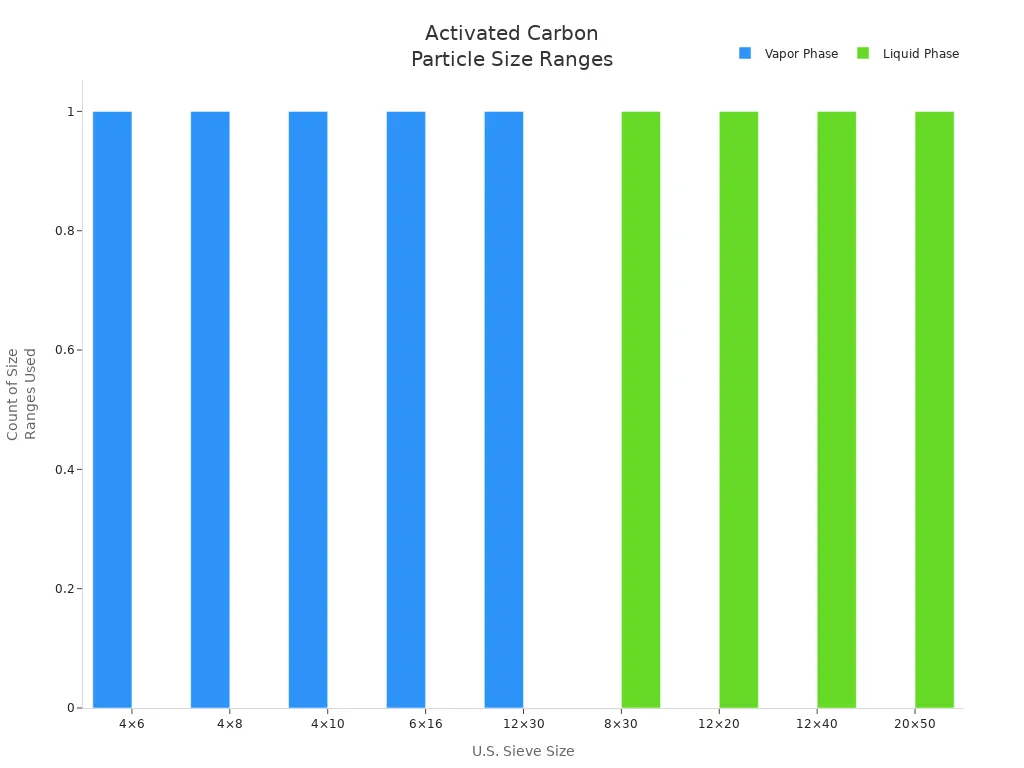

You have to pick the right particle size for your activated carbon. The size changes how well the carbon works in different systems. Bigger particles are used for vapor phase. Smaller particles are used for liquid phase. The table below shows some common sizes:

Phase | Common U.S. Sieve Sizes | Size Range Description |

|---|---|---|

Vapor | 4×6, 4×8, 4×10, 6×16, 12×30 | Covers 85-95% of total product |

Liquid | 8×30, 12×20, 12×40, 20×50 | Usually somewhat smaller than vapor phase |

You can also see the difference in this chart:

Choosing the right size helps you control air or water flow. It also helps you get the best adsorption rate.

Surface Area

You want your carbon to have a high specific surface area. This means the carbon has lots of tiny pores where pollutants can stick. More micropores mean higher specific surface area. If you increase microporosity, the carbon traps more pollutants.

More surface area helps you get better results in the impregnation process.

The table below shows how changing the impregnation ratio affects surface area:

Impregnation Ratio | Specific Surface Area (m²/g) | Observations |

|---|---|---|

1.0:1 | < 3000 | Initial increase in surface area |

4.0:1 | > 3000 | Maximum surface area achieved |

> 4.0:1 | Decrease | Excessive ablation of carbon materials leads to reduced surface area |

You should try to find the best balance. Too much treatment can lower the surface area and make the carbon less useful.

Cleaning and Drying

You need to clean and dry the carbon before adding chemicals. This step removes dust and things that block the pores. Follow these steps to get your carbon ready:

Stop using the filter and get it ready for cleaning.

Take apart the filter with the right tools.

Remove dust and dirt with a soft brush or vacuum.

Rinse the carbon bed to wash away impurities.

Put the filter in a cleaning solution.

Rinse again to remove leftover cleaner.

Air dry the filter in a place with good airflow so it does not get wet.

Put the filter back together and install it when dry.

Tip: Dry carbon works better for impregnation. Water can block the pores and make the process less effective.

When you follow these pre-treatment steps, your carbon works better in the next stages. You get higher adsorption and longer life for your product.

Solution Preparation

Choosing Impregnants

You have to pick the right chemicals for your impregnation solution. The chemical you choose depends on the pollutant you want to remove. For example, sulfur is best if you want to get rid of mercury in the air. Research shows sulfur-impregnated activated carbon works better for mercury vapors than other choices. Sulfur helps the carbon trap both elemental and organic mercury. You can use other chemicals for different pollutants, but always match the chemical to your need.

Sulfur: Best for mercury removal from air.

Silver: Good for bacteria and oxidation.

Copper: Useful for ammonia and cyanide.

Potassium permanganate: Helps with organic compounds.

Tip: Always make sure your chemical works well with your type of activated carbon.

Concentration and pH

You need to make your impregnation solution with the right concentration and pH. These two things affect how well the chemicals stick to the carbon. They also affect how much pollutant the carbon can trap later. Most experts say to use a concentration between 0.1 and 0.5 mol/L. This range gives enough chemical to cover the carbon but does not waste it. The pH should be between 3 and 5. This slightly acidic level helps the chemicals bond to the carbon.

Parameter | Recommended Range |

|---|---|

Concentration | 0.1–0.5 mol/L |

pH | 3–5 |

If you use the right concentration and pH, the carbon traps more pollutants and works better.

Mixing Methods

You need to mix your impregnation solution well so the chemicals spread evenly. Good mixing makes sure every piece of carbon gets the same amount of chemical. You can stir by hand for small batches. For bigger amounts, you might use machines or even ultrasonic waves. Ultrasonic mixing breaks up clumps and helps the solution reach deep into the carbon pores.

Stirring: Works for small batches.

Mechanical mixing: Good for medium to large batches.

Ultrasonic mixing: Best for deep and even coverage.

Note: Always check that your mixing method does not break the carbon pieces. Gentle mixing keeps the carbon strong for the next steps.

If you follow these steps, your impregnation activated carbon will work its best. The right solution and mixing help you get great results every time.

Impregnation Process

When you do the impregnation step, you help make activated carbon better. This step lets you add special chemicals to the carbon. These chemicals help the carbon work better for certain jobs. There are different ways to add the chemicals. Each way changes how the chemicals spread and how well the carbon works.

Equal-Volume Method

The equal-volume method is a simple way to add chemicals. You mix the carbon with a solution that is the same amount as the carbon. This stops you from wasting chemicals. It also helps the chemicals cover the carbon evenly.

First, you measure the dry activated carbon.

Next, you make a solution with the chemical you want.

Then, you pour the solution so it matches the carbon’s amount.

You mix gently so the solution goes into the pores.

This method is good for small batches. You can control how much chemical you add. It is used for making carbon for air filters or water cleaning. The equal-volume method is easy to repeat and keeps things simple.

Tip: Always check that the solution covers all the carbon. If some carbon is not covered, it will not work as well.

Injection and Soaking

Injection and soaking help chemicals go deeper into the carbon. You can inject the solution into the carbon bed. Or you can soak the carbon in a bath of chemicals. This helps the chemicals reach inside the pores.

You use pumps or syringes to inject the solution.

You can also soak the carbon for a set time.

The chemicals move into the pores by spreading out.

Soaking can leave some unwanted liquid behind. Supercritical CO2 impregnation is cleaner and loads more chemicals. For example, supercritical CO2 can load 3.4% drug, but soaking only loads 1.3%. Soaking may also cause chemicals to come out too fast. Supercritical CO2 gives a slower, more controlled release.

Supercritical impregnation uses special fluids that move fast and spread well. This helps the chemicals go into the carbon quickly and evenly. You get better chemical spread inside the carbon. This method is good when you need high performance and clean results.

Soaking can leave some liquid behind.

Supercritical CO2 does not leave liquid and gives better control.

Even spread helps the carbon work better.

Ultrasonic Oscillation

Ultrasonic oscillation uses sound waves to shake the solution and carbon. The shaking helps the chemicals move into the pores and spread out.

Parameter | |

|---|---|

Surface Area (SBET) | 29.05 |

Micropore Volume (Vmic) | 30.23 |

Mesopore Volume (Vmes) | 113.33 |

Ultrasonic oscillation makes more pores and more surface area. This gives more places for pollutants to stick. The sound waves help mix the chemicals better. You get a more even spread, especially for metals like palladium.

You get better mixing of chemicals.

You get more mesopore area compared to total area.

You spread active parts better.

Note: Ultrasonic oscillation helps you make better impregnated activated carbon. You can use it for special jobs, like removing hard-to-catch pollutants or making the carbon trap more stuff.

You can also use new technology to make the process better. AI and machine learning help you design better carbon. Special tools like scanning electron microscopy and high-performance liquid chromatography help you see how the process works. Immersion calorimetry helps you connect pore shape to how the carbon traps things. These tools help you make carbon that works better and costs less.

Different pore sizes change how well the carbon traps gases like CO2. For example, using NaOH can make the carbon trap 142% more CO2. You can use these ways to make your carbon work better for different jobs.

Post-Treatment

After you finish the impregnation step, you need to treat the carbon so it works well in real applications. Post-treatment makes sure the chemicals stay on the carbon and the product is safe to use. You will go through three main steps: separation, drying, and curing.

Separation

You start by separating the pre-treated activated carbon from the leftover solution. This step removes extra liquid and helps you keep only the carbon with the right amount of chemicals. You can use a filter or a centrifuge for this job. A filter lets the liquid drain away while keeping the carbon in place. A centrifuge spins the mixture fast, which pushes the liquid out and leaves the carbon behind. Make sure you do this step carefully so you do not lose any carbon or chemicals.

Tip: If you remove too much liquid too quickly, you might lose some of the chemicals you just added. Take your time and check the carbon after separation.

Drying

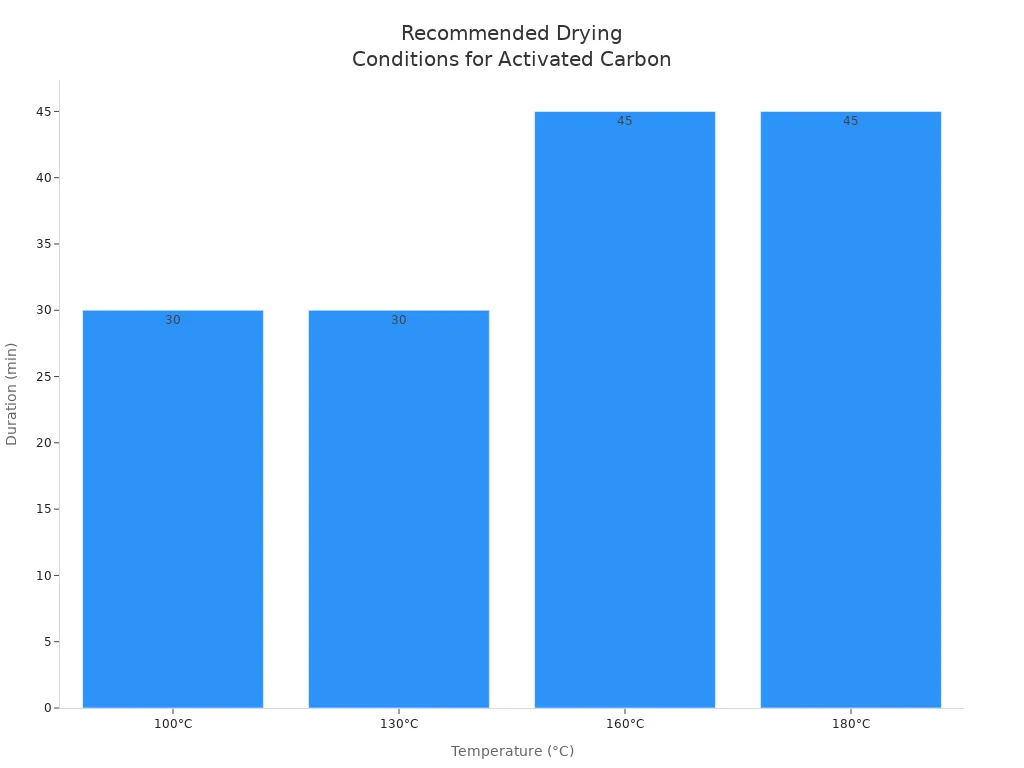

Next, you need to dry the carbon. Drying and activation are important because water left in the carbon can block the pores and lower performance. You want the carbon to be dry but not burned. The temperature that can cause combustion in modified activated carbon is between 175 and 180 °C. You should keep the temperature below this level to stay safe.

Here are some common drying temperatures and times:

100 °C for 30 minutes

130 °C for 30 minutes

160 °C for 45 minutes

180 °C for 45 minutes

You can see these drying options in the table below:

Temperature (°C) | Duration (min) |

|---|---|

100 | 30 |

130 | 30 |

160 | 45 |

180 | 45 |

You should pick the right temperature and time for your carbon. If you dry it too fast or too hot, you might damage the carbon. If you dry it too slow, you might not remove all the water.

Curing

The last step is curing. Curing helps the chemicals stick to the carbon and makes the product stable. You usually heat the carbon at a lower temperature for a longer time. This step locks the chemicals in place and stops them from washing away during use. Good curing improves the carbon’s performance and makes it last longer. You can test the carbon after curing to make sure it meets your needs.

Note: Curing is not the same as activation. Activation opens up the pores in raw carbon, while curing happens after impregnation to set the chemicals.

When you follow these post-treatment steps, you get activated carbon that works well for your job. You can trust that the carbon will trap pollutants and stay strong during use.

Quality Control

Quality control helps you make sure your impregnated activated carbon works well and meets industry rules. You need to check if chemicals are spread out evenly. You also test how well the carbon removes pollutants. Watching the process closely helps you get better and safer products.

Uniformity Testing

Uniformity testing checks if chemicals cover the carbon the same way everywhere. You want each piece of carbon to have the same amount of chemical. If chemicals are not spread out, some carbon will not work as well. You can use easy tests like looking at color. You can also use special tools like scanning electron microscopes. These tools help you see if chemicals are on the surface or deep in the pores.

You can use a table to keep track of your results:

Test Type | What It Shows | Why It Matters |

|---|---|---|

Color Check | Evenness of coverage | Quick and easy |

Microscopy | Chemical distribution | Detailed and accurate |

Tip: Always test samples from different spots in your batch. This helps you find problems early.

Effectiveness Checks

Effectiveness checks show how well your carbon removes pollutants. You can do lab tests to see how much gas or metal the carbon can trap. Many labs use adsorption isotherms, like the Langmuir and Freundlich models, to measure how much pollutant the carbon can hold. These tests help you know if your impregnation process worked.

You can follow these steps for effectiveness checks:

Take a sample of your activated carbon.

Expose it to a set amount of pollutant.

Measure how much pollutant the carbon removes.

Compare your results to industry rules.

If your carbon meets or beats the standard, your process is good. If not, you may need to change your steps.

Process Monitoring

Process monitoring means you watch every step as you make your product. You check temperatures, times, and chemical amounts. You also write down what happens with each batch. This helps you find problems before they get big.

You can use a checklist to help you:

Check solution concentration before impregnation.

Record drying temperature and time.

Test samples after curing.

Keep all records for future checks.

Note: Many companies follow ISO or ASTM standards for quality control. These standards give you best ways to work and help you make safe, high-quality products.

When you use good quality control, you get activated carbon that works better. You also make sure your product is safe and ready to use.

Applications and Challenges

Gas Removal

Impregnated activated carbon is used to clean gases. It helps remove bad chemicals from air in factories, labs, and homes. This carbon can trap things like sulfur gases, mercury, and VOCs. It works well because it can catch more pollutants than regular carbon. People use the iodine value to see how good the carbon is. If the iodine value is high, the carbon can hold more chemicals.

Here is a table that shows where you use this carbon for gas removal:

Application | Description |

|---|---|

Air purification | Takes out VOCs, mercury, and sulfur gases from air. |

Gas processing | Catches sulfides, mercaptans, acidic gases, and mercury. |

Chemical processing | Cleans up dangerous chemicals to keep people and nature safe. |

Tip: Always check the iodine value before using carbon for gas removal. This helps you choose the best carbon for your job.

Mercury and VOCs

You can use impregnated activated carbon to take out mercury and VOCs from factory smoke. Sulfur-impregnated granular activated carbon is great for mercury. It can remove 90% to 95% of mercury. This is important in oil and gas plants, where mercury can get into the air. You also use this carbon to trap VOCs. Changing the carbon with chemicals makes it better at catching these pollutants. In coal power plants, you often add activated carbon before other filters. This helps control mercury in the smoke. If there are nitrogen oxides and hydrogen chloride, the carbon works even better for mercury.

You should test the iodine value and iodine number of your carbon. These tests show how much pollution the carbon can hold. A high iodine value means the carbon is strong at trapping chemicals.

Note: You need to pick the right type of impregnated activated carbon for each pollutant. This helps you get the best results and keeps the environment safe.

Common Issues

There are some problems you might face when making impregnated activated carbon. You have to control the temperature, pressure, and mixing during the process. The materials you use and your goals can change how you do things. You must follow the right steps to get good results.

Here are some common problems you might see:

You need the right temperature and pressure.

The process changes if you use different materials.

You must do each step correctly to get good carbon.

If you do not control these things, your carbon might not work well. It could have a low iodine value or not trap enough pollution. You should always watch your process and test your carbon. This helps make sure your carbon works for gas removal, mercury, and VOCs.

Tip: Test your carbon often and control your process carefully. This helps you avoid problems and keeps your product strong.

You now know the impregnation process in activated carbon making has many steps. First, you get the carbon ready. Then, you mix the right solution. Next, you add the chemicals to the carbon. Last, you treat the carbon again to finish. This process helps you make carbon that fits your needs:

You can use it to clean air or water.

It helps remove hard-to-catch things like hydrogen sulfide.

It can stop germs in water.

Quality checks make sure your carbon works well. But this process uses a lot of energy and makes more CO₂ than some other ways. Always think about how impregnation changes both how the carbon works and its effect on the environment.