医用干燥剂

购买医用干燥剂

医用干燥剂是用于关键任务的湿度管理产品。医用干燥剂用于在运输、储存和/或使用过程中保护对湿气敏感的医疗设备、药品、诊断产品和装置。干燥剂的设计目的是捕捉和保持环境中的水蒸气,以防止冷凝、化学降解、药效降低、微生物滋生和金属部件腐蚀。主要形式有:高纯度硅胶(始终符合 USP / EP 标准)、分子筛(粘土)(干燥剂包装在特卫强® 袋或罐中,用于洁净室应用)。.

行业挑战

法规与安全合规

- 符合全球严格的生物相容性、安全性(如 USP VI 级)和纯度规定(FDA、EMA)。.

- 确保沥滤物/萃取物的最小化和全面的可追溯性。.

- 证明与药物/器械直接接触的安全性,这对所有类型(二氧化硅、蒙脱石、纤维、钙/镁氯化物)都至关重要。.

材料性能与完整性

- 在所有干燥剂类型中保持超高的材料纯度,防止产品污染。.

- 确保与受保护产品的兼容性(例如,避免 CaCl₂/MgCl₂ 等氯化物的腐蚀,避免 attapulgite/montmorillonite 等粘土的粉尘)。.

- 防止可能损害设备/药品的物理退化(如破损、灰尘)。.

包装和工艺要求

- 开发坚固耐用的包装(如用于硅胶、纤维的特卫强®),可经受灭菌(伽马射线、ETO、电子束)而不失效。.

- 最大限度地减少处理和使用过程中产生的棉絮/粉尘(尤其是粘土干燥剂与纤维干燥剂)。.

- 确保包装完整性,保持无菌屏障和干燥剂功能。.

验证和性能保证

- 准确计算各种产品和气候条件所需的干燥剂容量/正确类型。.

- 在整个产品保质期内显示出一致且可预测的吸附性能。.

- 验证复杂协议在实际条件下的性能。.

为什么选择我们的干燥剂

加强监管保证

我们的干燥剂在纯度、生物相容性和安全文件方面始终符合并超过严格的全球标准(FDA、EMA、USP/EP)。.

卓越的材料兼容性

设计用于防止污染、腐蚀和与敏感医疗产品之间的各种类型(二氧化硅、氯化物、粘土、纤维)的相互作用风险。.

保证性能可靠性

在各种极端的储存或运输条件下提供可预测的高效吸湿性。.

全面的供应链支持

针对复杂的医疗行业需求,提供始终如一的质量、可靠的可用性和专业技术。.

优化安全和清洁

其特点是最大限度地减少粉尘、破损和可浸出物,确保关键应用的物理和化学安全。.

使用方法

药品包装(小瓶、泡罩包装)

使用概述

干燥剂(主要是硅胶和分子筛)被集成到药品包装中,以保护对湿度敏感的药物、药片和胶囊不被降解。.

主要优势

- 保持稳定性:防止水解,保持活性药物成分的化学完整性

- 延长保质期:为吸湿性药物创造最佳的低湿度环境

- 符合法规要求:USP/EP 级硅胶符合药典标准,可直接接触药物

- 清洁操作:无除尘纤维干燥剂可防止自动泡罩包装生产线受到污染

医疗设备和仪器保护

使用概述

蒙脱石、芒硝和硅胶罐可在消毒、储存和运输过程中保护手术工具、电子设备和光学设备。.

主要优势

- 防腐蚀:粘土干燥剂(蒙脱石/阿塔波尔石)可吸收导致金属器具生锈的水分

- 电子保护:硅胶保护诊断设备中的敏感电路免受潮湿损坏

- 物理弹性:非易碎格式在设备处理和运输过程中不易破损

- 灭菌兼容性:干燥剂包装在伽马/环氧乙烷灭菌周期后仍能保持完整性

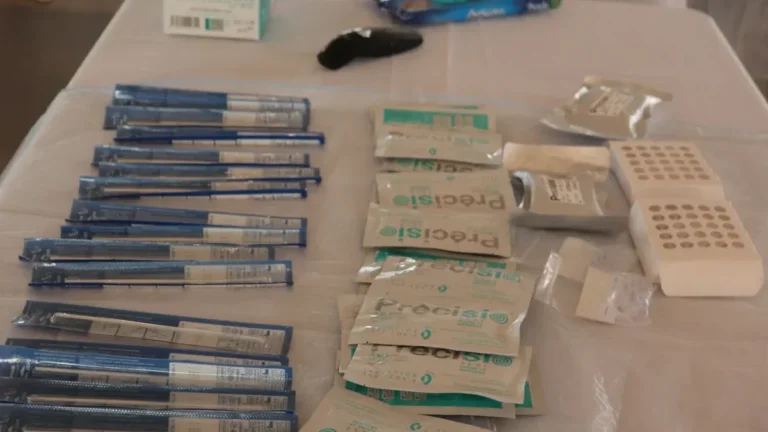

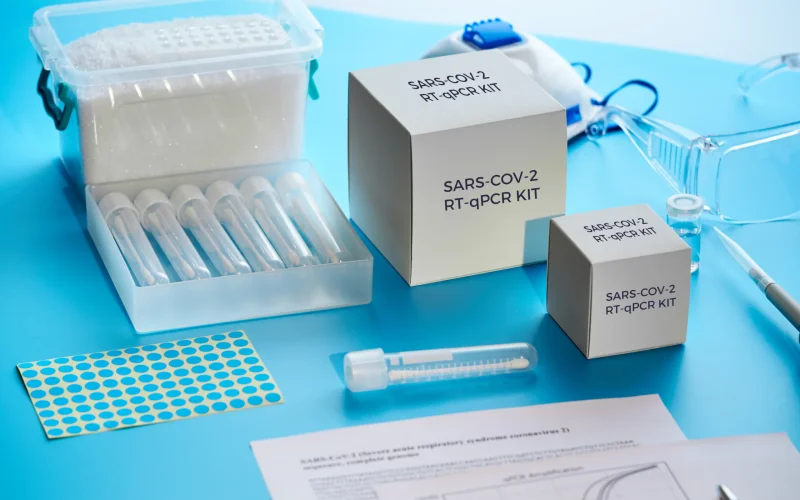

诊断试剂和检测包保存

使用概述

硅胶和纤维干燥剂可保持密封袋中诊断条、试剂和侧流测试包的准确性。.

主要优势

- 湿敏保护:防止酶基试剂过早活化

- 低微粒:纤维干燥剂可消除灰尘对微流控测试组件的干扰

- 性能均匀:在不同温度条件下提供一致的湿度控制

- 紧凑集成:小袋包装外形纤薄,适合小型测试套件包装,功能不受影响

植入物和无菌屏障系统

使用概述

高纯度氯化钙(CaCl₂)、氯化镁(MgCl₂)和硅胶可在植入物和一次性使用设备的无菌阻隔包装中保持干燥环境。.

主要优势

- 生物相容性保证:超纯氯化物可防止在直接接触植入物的情况下发生浸出物

- 高容量保护:氯化钙可在长期储存中提供出色的吸湿性

- 温度适应性:氯化镁可在高温下保持吸附效率

- 保持无菌:与所有灭菌方法兼容,不会产生内毒素