You use a dessecante de fibra to keep things dry and fresh. This plant-based product controls moisture very well. Fiber desiccant is made from cellulose materials and follows FDA rules. You can use it for food or medicine. You find it in packaging as thin sheets that soak up water. It does not leave any chemicals behind. Fiber desiccant gives you high absorption, is biodegradable, and is safe. When you pick a Dessecante alimentar, you protect food quality and follow strict rules. Fiber desiccant helps you keep things safe and dry.

Principais conclusões

Fiber desiccants come from plant fibers. They break down naturally. This makes them safe for the earth.

They soak up five times more water than silica gel. This gives better protection for food, medicine, and electronics.

Using fiber desiccants stops things from going bad. They keep products fresh. They do not leave anything harmful behind.

These desiccants meet FDA safety rules. This means they are safe for food and drug packages.

Fiber desiccants work in many industries. They help with food storage, medicine, and electronics. They are useful in many ways.

Putting fiber desiccants in the right spot helps them work better. The right size also helps control moisture.

Check fiber desiccants often. Replace them to keep them working well.

Picking fiber desiccants helps the planet. It cuts down on plastic waste in packages.

Fiber Desiccant Basics

What Is a Fiber Desiccant

Fiber desiccants help keep things dry and safe. They come from plant fibers, so they are good for the environment. These desiccants break down naturally over time. Makers use food-grade calcium chloride to help them soak up water better. You can trust fiber desiccants because they follow FDA rules for food safety. If you pick fiber desiccants, you do not use plastics, salts, or dust. This gives you a clean and safe way to pack food, medicine, and electronics.

How Fiber Desiccants Work

Fiber desiccants pull in water because of their special chemical makeup. Plant fibers have pectin, hemicelluloses, and lignin inside. Pectin has groups that grab onto water using hydrogen bonds. The fibers have tiny holes that let water get inside and stay there. When fiber desiccants touch moisture, their hydroxyl groups change old bonds and make new ones with water. This makes the fibers swell and hold water tightly. You get strong moisture control with no leaks or leftover chemicals.

Tip: Fiber desiccants can soak up five times more water than silica gel. This means your products stay safer.

Propriedades principais

Fiber desiccants have many features that make them special:

Made only from biodegradable plant fiber

Soaks up five times more water than silica gel

Leaves no leaks, residue, or bad chemicals

Safe for food contact and follows FDA rules (21CFR175.300)

Certified compostable by SGS

Soft, reusable, and works the same every time

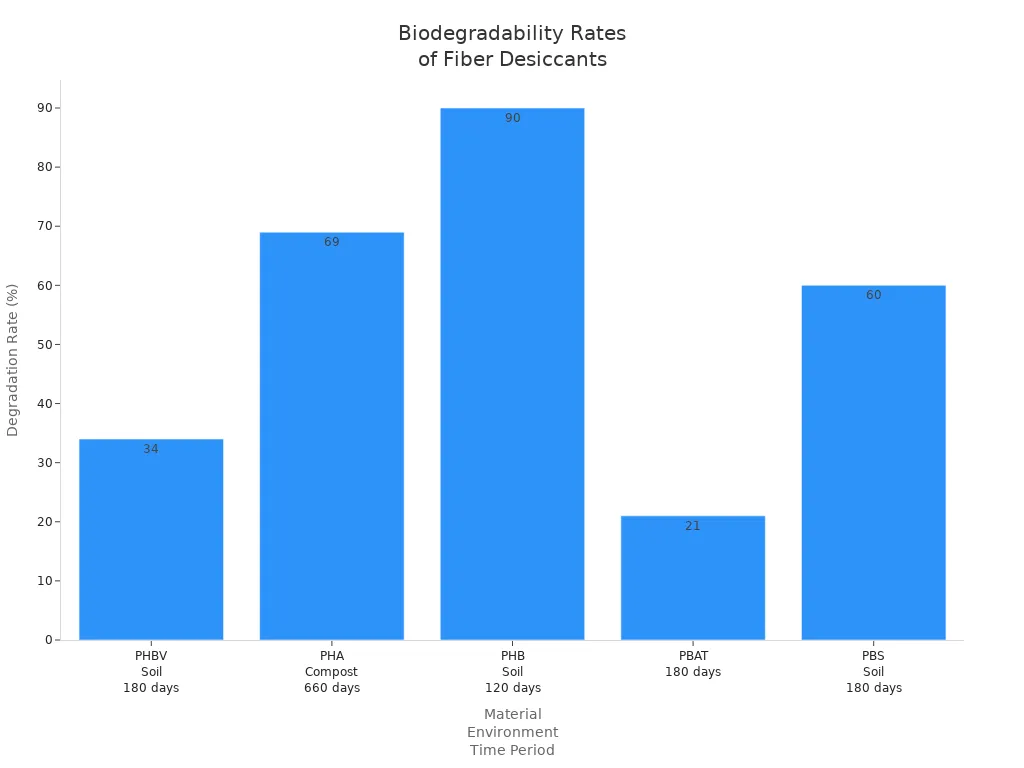

You can see how fiber desiccants break down in compost and soil. The table below shows how fast different materials in fiber desiccants break down:

Material | Environment | Temperatura | Degradation Rate | Time Period |

|---|---|---|---|---|

PLA | Composto | <30 °C | Very slow | N/A |

PHBV | Soil | 25 °C | 34% | 180 days |

PHA | Composto | 20 °C | 69% | 660 days |

PHB | Soil | 25 °C | 90% | 120 days |

PBAT | N/A | N/A | 21% | 180 days |

PBS | Soil | 30 °C | 60% | 180 days |

You can also look at the chart below to see how fast fiber desiccants break down in different places:

Fiber desiccants soak up lots of water, leave no mess, and break down well. You keep your products safe and help the planet too.

Fiber Desiccants in Use

Produtos farmacêuticos

Medicines need protection from moisture. Fiber desiccants keep tablets and capsules safe. They also protect medical equipment. You find desiccant paper in tablet bottles and blister packs. It is also in injectable bottles and vials. These desiccants block water from getting inside. This stops damage to your products. Fiber desiccants help keep medicine strong and stable. They stop loss of potency. Your medicine stays good for longer.

Medicinal products

Medical equipment

Tablet bottles

Blister packs

Injectable bottles

Vials

Desiccant paper guards these packages from moisture. This prevents spoilage. Your medicine stays effective longer. Fiber desiccants are safe and clean for packaging.

Note: Fiber desiccants do not leave residue or dust. You can use them with sensitive medical items.

Eletrónica

Electronics need to stay dry to work well. Fiber desiccants control moisture in boxes and cans. They also work in sealed bags. Desiccant paper protects circuit boards and chips. It also helps sensors stay safe. Fiber desiccants work better than silica gel for many electronics. They soak up more water. They break down safely after use.

Caraterística | Gel de sílica | Fiber Desiccants (e.g., Zorbette Dri-Tabs) |

|---|---|---|

30-40% of weight | Up to 100% of weight | |

Material | Synthetic | Natural fibers and hygroscopic compounds |

Eco-Friendliness | Non-biodegradable | Biodegradable and renewable |

Fiber desiccants give you better moisture control. They help electronics last longer. You help the environment by choosing biodegradable options.

Food Storage

You want food to stay fresh and safe. Fiber desiccants help store dry snacks and baked goods. They also protect spices. Desiccant paper works in cans, boxes, and buckets. It keeps food crisp and tasty. Fiber desiccants are good for low oil foods. These include nuts, tea, and dried vegetables.

Packaged dry snacks

Baked goods

Confectionery

Spices

Powdered ingredients

Dried meats

Jerky

Premium tea and coffee

Fiber desiccants stop mold and spoilage. They keep food from getting soggy or stale. You can use desiccant paper in chips, crackers, and cereals. This helps food keep flavor and texture. Fiber desiccants help seasoning stick to snacks. They also stop clumping.

Fiber desiccants control moisture without changing taste. You can trust desiccant paper to keep food safe and fresh.

Packaging and Logistics

You want your products to stay fresh and safe. Fiber desiccants are important for packaging and shipping. You can use desiccant paper in bottles, caps, cans, boxes, and buckets. These help control moisture when you ship or store things. They protect food, medicine, and electronics from getting ruined.

Moisture can cause mold, rust, or spoilage when you pack goods. You need desiccants to keep things dry. Desiccant paper soaks up water fast. You can put it inside packages or containers. This keeps your products safe until they reach customers.

Desiccants are found in many kinds of packaging. You see them in food boxes, medicine bottles, and electronic parts. Desiccant paper works well in sealed packages. You can use it for big shipments or single items. Every package gets good moisture control.

Tip: Put desiccant paper near the top of the package. This lets it soak up moisture before it touches your products.

You can pick different sizes and shapes of desiccants. Some are sheets, strips, or pads. You choose what fits your package best. Desiccant paper fits into small spaces. You do not need extra room in your box or bucket.

Here is a table that shows where you can use desiccants and desiccant paper in packaging:

Package Type | Use of Desiccants | Use of Desiccant Paper |

|---|---|---|

Bottles | Sim | Sim |

Caps | Sim | Sim |

Cans | Sim | Sim |

Boxes | Sim | Sim |

Buckets | Sim | Sim |

Using fiber desiccants helps your business. You have less waste and fewer returns. Your products stay safe from moisture. Desiccant paper is an easy way to help with packaging and shipping. Your goods arrive in great shape.

You also help the planet. Fiber desiccants break down after you use them. You do not add plastic or chemicals to your shipments. Desiccant paper is safe for food and medicine. You follow safety rules and keep your customers safe.

You can trust desiccants and desiccant paper for all your packaging. You get strong moisture control and help the environment. Your products stay fresh from the warehouse to the customer.

Fiber Desiccant Advantages

Absorption Efficiency

You want your things to stay dry. Fiber desiccants control moisture very well. They soak up five times more water than silica gel. This means food, medicine, and electronics get better protection. Plant fibers in fiber desiccants have tiny holes. These holes trap water and keep items safe from mold. You can use fiber desiccants in bottles, boxes, and cans. There are no leaks or mess. The desiccant holds water tightly for a long time. You see good results at room temperature, about 77℉ (25℃). Your products stay fresh and dry.

Tip: Pick fiber desiccants for things that need extra moisture protection. They work better than other desiccants.

Safety and Compliance

Safety is important to you. Fiber desiccants help you follow strict rules for food and medicine. They use natural plant fibers and food-grade calcium chloride. There are no plastics or bad chemicals inside. Fiber desiccants meet FDA standards for safe contact with food and drugs.

Fiber desiccants are safe for food packaging.

You can use them with medicine, snacks, and electronics.

Studies show fiber desiccants do not harm people. You can trust them for sensitive uses. They do not leave dust or residue. Your products stay clean and safe.

Caraterística | Fiber Desiccants | Outros dessecantes |

|---|---|---|

FDA Compliance | Sim | Sometimes |

Non-Toxic | Sim | Varia |

Residue-Free | Sim | Not always |

Environmental Benefits

You help the earth when you pick fiber desiccants. They come from renewable plants. They break down after use, so you do not add waste. Fiber desiccants support green packaging and shipping.

Fiber desiccants work in many climates. They soak up moisture in high and low humidity. Their performance changes with temperature. Higher temperatures can make them absorb more water at first. If it gets too hot, they may let some water go. You get the best results in normal storage.

Note: Fiber desiccants are 100% biodegradable. You protect your products and the planet at the same time.

You make a smart choice for your business and the earth. Fiber desiccants give you strong moisture control, safety, and eco-friendly benefits.

Versatilidade

You need something that keeps things dry in many ways. Fiber desiccants can do this job well. You can use them for food, medicine, electronics, and shipping. Their plant-based design makes them safe for sensitive items. You do not have to worry about bad chemicals or leftover mess.

Fiber desiccants come in different shapes and sizes. You can find sheets, strips, pads, and special pieces. This helps you pick the right one for your package. You can put a small pad in a pill bottle. You can use a big sheet in a shipping box. You choose what fits your product best.

Tip: You can cut fiber desiccant sheets to fit odd-shaped packages. This helps you protect every item, no matter the size.

Many industries use fiber desiccants. Food companies use them to keep snacks fresh. Medicine makers use them to protect tablets and capsules. Electronics makers put them in boxes to stop water damage. Shipping teams use them in containers and pallets. You can trust fiber desiccants in all these places.

Here is a table that shows where you can use fiber desiccants:

Indústria | Utilizações comuns | Fiber Desiccant Form |

|---|---|---|

Food | Snacks, spices, tea, coffee | Sheets, pads, strips |

Produtos farmacêuticos | Tablets, capsules, vials | Pads, strips, sachets |

Eletrónica | Circuit boards, sensors | Sheets, pads |

Logistics | Shipping boxes, containers | Large sheets, rolls |

You do not need special tools to use fiber desiccants. You just put them inside your package. They start working right away. You can use them in closed or open containers. They keep working even if you open and close the package.

Fiber desiccants work in many places. You can use them in hot, cold, dry, or wet areas. They keep soaking up water at room temperature, about 77℉ (25℃). You do not see leaks or mess. Your products stay safe.

Some fiber desiccants can be used again. If you dry them out, they soak up water again. This saves you money and cuts down on waste. You help the earth by using something more than once.

Note: Fiber desiccants work with low-oil foods like nuts and dried vegetables. They do not change taste or texture.

You get strong moisture control and lots of choices. Fiber desiccants fit many products and packages. You keep your goods safe and follow safety rules. You make a smart choice for your business and the planet. Fiber desiccants give you the flexibility you need for modern packaging.

Desiccant Comparison

Fiber Desiccant vs Silica Gel

Silica gel is found in shoe boxes and electronics. It traps water in tiny holes. Fiber desiccants use plant fibers and calcium chloride. They soak up moisture better than silica gel. Fiber desiccant paper holds much more water. It can hold five times more water than silica gel. You do not see leaks or dust with fiber desiccants. Silica gel sometimes leaves beads or powder behind.

Caraterística | Fiber Desiccant Paper | Gel de sílica |

|---|---|---|

Absorption Capacity | Very high | Moderado |

Safety for Food | Sim | Sometimes |

Biodegradable | Sim | No |

Residue-Free | Sim | Not always |

Fiber desiccants break down in compost and soil. Silica gel does not break down. You help the planet by using fiber desiccant paper. You also get strong moisture control for food, medicine, and electronics.

Tip: Pick fiber desiccant paper for extra protection and green packaging.

Fiber Desiccant vs Clay

Clay desiccants come from minerals found in nature. You see them in shipping boxes and storage containers. Clay absorbs water but not as much as fiber desiccant paper. Fiber desiccants work better in humid places. Clay works best in cool and dry areas.

Fiber desiccant paper uses plant fibers. It is safe for food and medicine. Clay desiccants may have dust or small bits. Fiber desiccant paper does not have this problem. Fiber desiccants also soak up water faster.

Clay desiccants: Good for basic moisture control

Fiber desiccant paper: Best for high absorption and safety

You help the environment when you pick fiber desiccants. Clay desiccants do not break down quickly. Fiber desiccant paper is compostable and leaves no harmful residue.

Note: Use fiber desiccant paper for sensitive items and green packaging.

Fiber Desiccant vs Molecular Sieve

Molecular sieve desiccants trap water and gases in tiny holes. You find them in lab equipment and medical devices. Molecular sieves work well in very dry places. Fiber desiccant paper controls moisture at room temperature.

Fiber desiccants give you safer packaging. Molecular sieves may release dust or chemicals. Fiber desiccant paper does not do this. You can use fiber desiccants for food, medicine, and electronics. Molecular sieves are not always safe for food.

Caraterística | Fiber Desiccant Paper | Peneira molecular |

|---|---|---|

Absorption Speed | Fast | Very fast |

Food Safety | Sim | Not always |

Biodegradable | Sim | No |

Residue-Free | Sim | Not always |

Fiber desiccant paper comes in sheets, pads, and strips. Molecular sieves are usually beads or pellets. You can cut fiber desiccant paper to fit any package.

Tip: Use fiber desiccant paper for everyday packaging and storage. Pick molecular sieve desiccants for special lab uses.

Suitability Differences

You need to pick the right desiccant for your job. Each kind works best in different ways. You should check how well they work, if they are safe, and if they are good for the earth. Desiccant paper has many good points, but other types can be useful too.

Desempenho

Desiccant paper soaks up water fast. You can use it for food, medicine, and electronics. It keeps things dry for a long time at room temperature. Silica gel does not hold as much water, so you may need more packets. Clay desiccants work best in cool and dry places. Molecular sieve desiccants trap water very quickly, but you mostly see them in labs or special tools.

Segurança

You want your food and medicine to be safe. Desiccant paper follows FDA rules and does not leave dust or chemicals. You can use it with sensitive items. Silica gel is sometimes safe for food, but not always. Clay desiccants might leave dust, which can be a problem. Molecular sieve desiccants are not always safe for food or medicine.

Impacto ambiental

You care about helping the planet. Desiccant paper comes from plants and breaks down after use. It does not add plastic or chemicals to the earth. Silica gel and molecular sieve desiccants do not break down easily. Clay desiccants come from minerals, but they do not compost as well as plant-based ones.

Here is a table to help you compare which is best:

Tipo de dessecante | Best Use Cases | Safety for Food | Impacto ambiental | Absorption Speed |

|---|---|---|---|---|

Desiccant paper | Food, pharma, shipping | Sim | Biodegradable | Fast |

Gel de sílica | Shoes, electronics | Sometimes | Not biodegradable | Moderado |

Clay desiccants | Storage, shipping | Sometimes | Slow to degrade | Moderado |

Molecular sieve | Labs, medical devices | Not always | Not biodegradable | Very fast |

How to Choose

Think about what you need to keep dry. If you want strong moisture control and safety, desiccant paper is a smart pick. You can use it for snacks, pills, and electronics. If you ship things in hot or wet places, desiccant paper works well. Silica gel and clay desiccants are fine for simple jobs, but they are not as safe or good for the earth.

Tip: Always check if your desiccants are safe for your products. Desiccant paper helps you feel sure about food and medicine.

You can cut desiccant paper to fit any box or bag. You do not need special tools. You get strong moisture control and help the earth too. When you pick desiccant paper, you make a smart choice for your business and your customers.

Choosing Fiber Desiccants

Application Needs

You want to pick the right desiccant for your products. Start by thinking about what you need to keep dry. If you store food, medicine, or electronics, you need strong moisture control. Fiber desiccants work well for snacks, pills, and sensitive devices. You can use them in bottles, boxes, or bags. Each product needs a different amount of moisture protection. For example, dry foods like nuts and tea need a desiccant that keeps them crisp. Medicine needs a desiccant that stops pills from breaking down. Electronics need a desiccant that prevents rust and damage.

Tip: Match your desiccant to the type of product and how long you plan to store it. This helps you keep everything safe and fresh.

Environmental Factors

You must consider the environment where you store your products. Temperature and humidity change how well a desiccant works. When the air is hot, the desiccant can release moisture faster. Heat gives water molecules energy to leave the desiccant. If the air is very humid, the desiccant has to work harder to keep things dry. High humidity slows down how quickly the desiccant can release water. You get the best results when you store products at room temperature and keep humidity low.

Store products in cool, dry places for best desiccant performance.

Check the temperature and humidity in your storage area often.

Use more desiccant if you expect high humidity or heat.

Note: Fiber desiccants work best at room temperature, around 77℉ (25℃). You may need extra desiccant in hot or humid places.

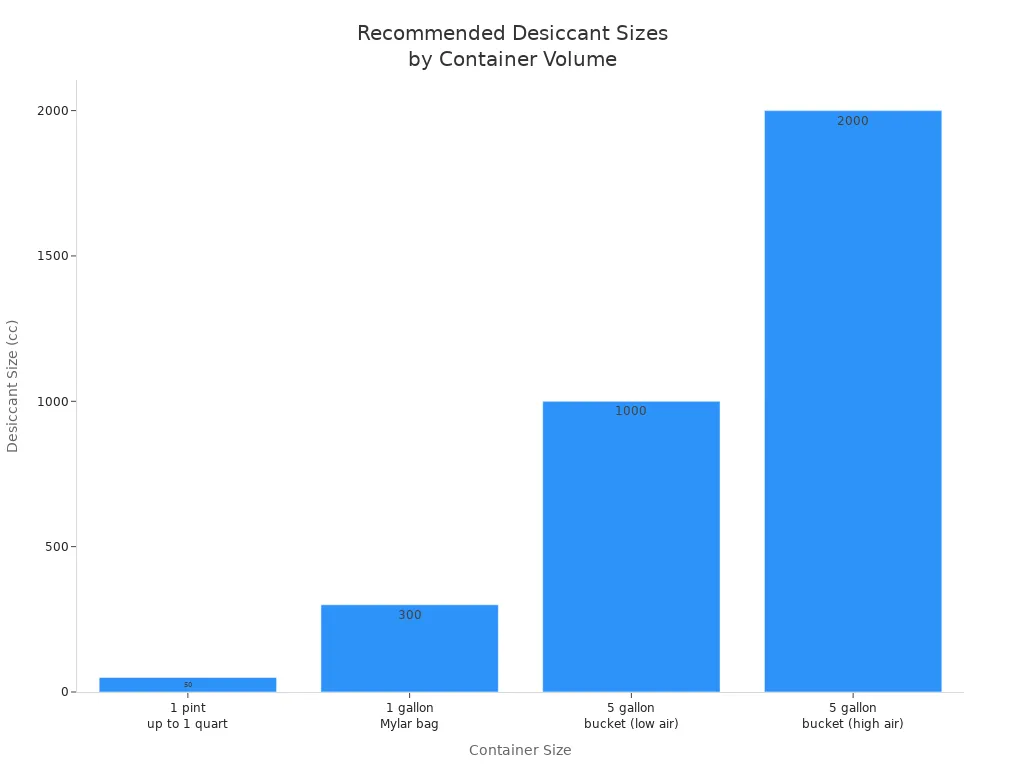

Size and Packaging

You need to choose the right size of desiccant for your container. If you use a small jar, you need a small desiccant. Big buckets or bags need larger desiccants. Using the right size helps you control moisture without wasting space. Industry guidelines show which desiccant size fits each container.

Container Size | Desiccant Size |

|---|---|

1 pint up to 1 quart Mason jar | 50cc |

1 gallon Mylar bag | 300cc |

5 gallon bucket (low air volume) | 1000cc |

5 gallon bucket (high air volume) | 2000cc |

You can use this table and chart to pick the right desiccant for your package. If you use a Mason jar, choose a 50cc desiccant. For a 1-gallon bag, use a 300cc desiccant. Large buckets need 1000cc or 2000cc, depending on how much air is inside. Always check your packaging size before you buy desiccants.

Tip: Use the right size desiccant to keep your products dry and avoid waste.

Safety Standards

You want your products to be safe. Fiber desiccants help you follow strict safety rules. You need to check if your desiccant meets rules for food, medicine, and packaging. These safety rules keep your customers and business safe.

Look for these important certifications:

FDA Compliance: Fiber desiccants must follow FDA rules for food contact. The FDA makes rules for things that touch food and medicine. You find these rules in 21CFR175.300. This means your desiccant does not let out bad chemicals.

SGS Certification: SGS checks products for safety and quality. You can trust fiber desiccants with SGS compostable certification. This shows your desiccant breaks down safely and does not hurt the earth.

ISO Standards: ISO makes global rules for quality and safety. Fiber desiccants with ISO certification meet high rules for making and testing.

REACH and RoHS Compliance: These European rules limit dangerous things. Fiber desiccants that follow REACH and RoHS do not have heavy metals or toxic chemicals.

Here is a table to help you check safety standards:

Safety Standard | What It Means | Porque é que é importante |

|---|---|---|

FDA (21CFR175.300) | Safe for food and drug contact | Protects health |

SGS Compostable | Breaks down in soil or compost | Good for the environment |

ISO Certification | Meets global quality rules | Ensures reliability |

REACH/RoHS | Limits harmful substances | Safer for people and planet |

You need to read product labels and certificates. You should ask your supplier for proof of these rules. You need to see test reports and certifications before you buy. You can also check for batch numbers and expiration dates. This helps you watch quality and safety.

Tip: Always pick fiber desiccants with clear safety certifications. You keep your products safe and build trust with your customers.

You should store fiber desiccants in clean, dry places. You must keep them away from chemicals and strong smells. You need to wear gloves if you handle a lot. You should never use damaged or expired desiccants.

You want to follow local laws and industry rules. You must check if your country has extra rules for packaging or food safety. You should update your safety checks every year. You need to teach your team to spot unsafe products.

You help your business when you follow safety rules. You avoid recalls and complaints. You keep your products fresh and safe. You show your customers that you care about their health.

You make smart choices when you pick fiber desiccants with strong safety rules. You protect your products, your customers, and the earth.

Using Fiber Desiccants

Placement Tips

You want your fiber desiccants to work well. Good placement helps you get the best moisture control. Start by making sure your packaging is clean and dry. This step keeps extra water out before you seal your items. Use the right amount of desiccant for your container size. Too little will not protect your products. Too much can take up space you need.

Place desiccants in spots where water collects easily. Corners and edges often trap moisture. In large boxes or buckets, spread the desiccants out. This stops wet spots from forming in one area. If you use more than one desiccant, put them in different places. This gives you even protection.

Choose the right number and type for your container.

Place desiccants in corners and near moisture-prone areas.

Spread them out in big packages for even coverage.

Check and replace desiccants if you see signs of dampness.

Tip: Even placement helps you avoid mold and spoilage. Your products stay fresh longer.

Storage and Handling

You need to store fiber desiccants the right way before you use them. If you leave them out, they can soak up water from the air. This makes them less effective when you need them most. Keep desiccant packets in airtight containers. This stops them from pulling in moisture too soon.

Store your desiccants in a cool, dry place. Heat and sunlight can damage the fibers. Pick a spot away from windows and heaters. Watch the humidity in your storage area. High humidity can lower the power of your desiccants.

Use airtight containers for storage.

Keep desiccants away from heat and sunlight.

Store in a cool, dry area.

Monitor humidity to keep desiccants strong.

Note: Proper storage keeps your desiccants ready for top moisture control when you need them.

Monitoring Effectiveness

You want to know if your fiber desiccants still work. Check them often, especially in humid places. Look for signs that they have soaked up too much water. If a desiccant feels soft, swollen, or heavy, it may be full. Some desiccants change color when they reach their limit.

Replace old or used desiccants right away. This keeps your products safe from moisture. If you store items for a long time, set a schedule to check your desiccants. Write down the date you added new ones. This helps you remember when to inspect and replace them.

Check desiccants for swelling or color change.

Replace them if they feel heavy or damp.

Set a regular schedule for inspections.

Record the date of each replacement.

Tip: Regular checks help you keep strong moisture control and protect your goods.

Encontra fiber desiccants in food, medicine, and electronics. They help keep things dry and safe. Reports say more companies want better moisture control now. The table below shows why fiber desiccants are popular:

Key Highlights | Descrição |

|---|---|

Demand rising | More businesses want to protect sensitive products. |

Fiber desiccants keep chips and sensors safe. | |

Food and pharma | They help food and medicine stay fresh. |

Regulations | New rules ask for safer, greener choices. |

Better formulas | New designs work better and help the earth. |

Fiber desiccants use natural fibers that break down, so they cut down on plastic trash.

You get safe and strong moisture control that is good for the planet.

The fiber desiccant market is growing quickly, with a 5.9% yearly growth rate.

Pick fiber desiccants if you want safe and earth-friendly moisture protection.